Send My Request

About us

Bost is a trusted engineering plastics manufacturer dedicated to research, production, and sales of high-performance plastics. We focus on innovation, quality, and customer satisfaction, serving industries worldwide with reliable material solutions.

Company Profile of Bost

Guangzhou BEST Rubber & Plastic Technology Co,ltd, operating under the brand Bost, is located in the No.21 liangtian Road, Liangtian Town industrial Park, Baiyun District, Guangzhou China. Bost is a professional and innovative high-tech manufacturer specializing in green energy engineering plastics. Since its establishment, Bost has been committed to the research, development, production, and sales of engineering plastics and special engineering plastics. Our mission is to deliver high-quality products and services while continuously striving for customer satisfaction.

Bost operates with integrity and a strong commitment to quality, meeting customer needs across China, Europe, America, and other international markets. Our products are widely recognized for their reliability and customer satisfaction. Over the years, Bost has developed a unique production management model, guided by the principles of customer satisfaction, trust, and quality service. Based on reciprocity, mutual benefit, and long-term cooperation, we continue to uphold balanced and sustainable business practices, striving to create win-win partnerships between employees and enterprises, businesses and society.

As a professional manufacturer, Bost specializes in the production of high-performance engineering plastics with exceptional properties, including ultra-high scratch resistance, superior corrosion resistance, fatigue durability, abrasion resistance, and high-temperature transparency. Our expertise also extends to toughening, flame retardancy, wave absorption, and thermal conductivity in modified engineering plastic sheets, rods, and molds. With a strong R&D team for plastics modification, in-house mold design and manufacturing, advanced machining capabilities, and an experienced production team, we deliver innovative solutions. In particular, our strength lies in steel-plastic and plastic-rubber composite applications, demonstrating advanced technology and strong production capacity.

We warmly welcome domestic and international manufacturers to collaborate with Bost. With your ideas and our expertise, we strive to turn inspiration into reality and achieve shared success.

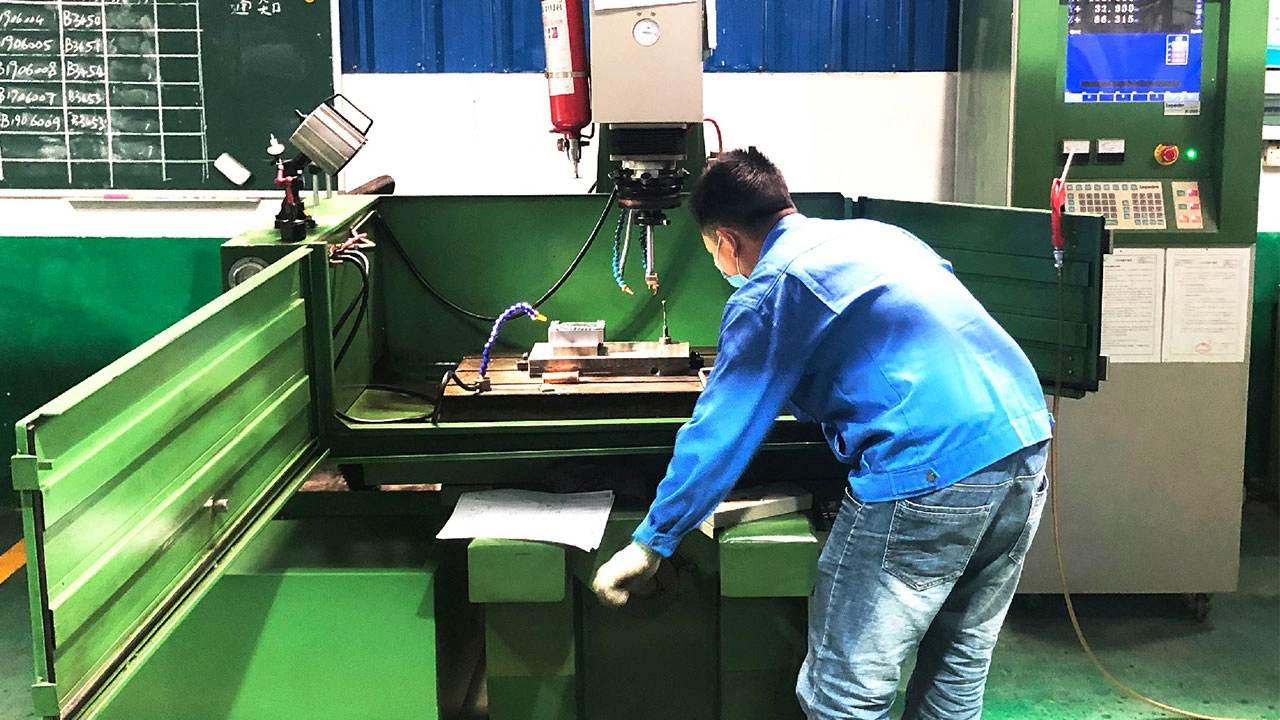

Bost's Processing strength

6

Gaskets, sealing rings, O-rings, V-rings, solid balls, bushings/bushings, screws, nuts, insulation kits, pipe fittings, pins, etc.

Engineering plastics PEEK, PPS, PFA, PTFE, PVDF, PSU, PE|, POM, PA6, UHMWPE, PE, PP, PVC, PCPMMA; metal: SS316, SS304, SS216.

5

O-ring, ∪-ring, V-ring, rubber sealing ring, rubber flat gasket, rubber valve seat, rubber ball, rubber-coated metal custom parts

FKM、FPM、Silicone Rubber、HNBR、CR、NBR、EPDM、NR。

11 (1 vertical injection molding machine, 1 80T injection molding machine, 2 120T injection molding machines, 1 320T injection molding machine, 1 220T injection molding machine, 5 150T injection molding machines

Plastic shells, customized plastic parts, gaskets, seal rings, O-rings, V-rings, bushings/bushings, screws, nuts, insulation kits, pipe fittings, gears, overmolding and insert molding, etc.

Engineering plastics PEEK, PPS, PFA, PTFE, PVDFPSU, PE|, POM, PA6, UHMWPE, PE, PP, PVC, PCPMMA, TPE elastomer.

4

O-ring, ∪-ring, V-ring, rubber sealing ring, rubber flat gasket, rubber valve seat, rubber ball, rubber-coated metal custom parts

FKM、FPM、Silicone Rubber、HNBR、CR、NBR、EPDM、NR。

3

Injection mold

4

Injection molding models, customized plastic parts

2

Injection mold

The Milestones That Shaped Bost

Bost Brand Concept

Frequently Asked Questions

FAQs

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

Leave a Message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code