Send My Request

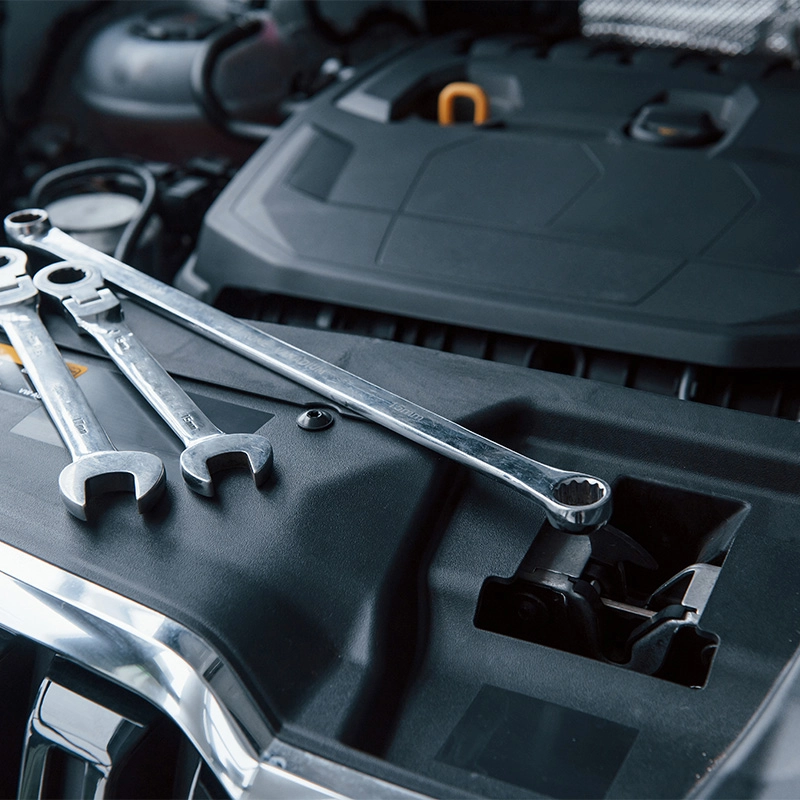

Automotive Industry

Bost specializes in engineering plastics & special engineering plastics for the automotive industry, providing materials that improve strength, reduce weight, and enhance resistance to heat and wear, ensuring high-quality vehicle performance.

Key Trends & Advantages

Engineering Plastics

Special Engineering Plastics

Leave a Message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code