Send My Request

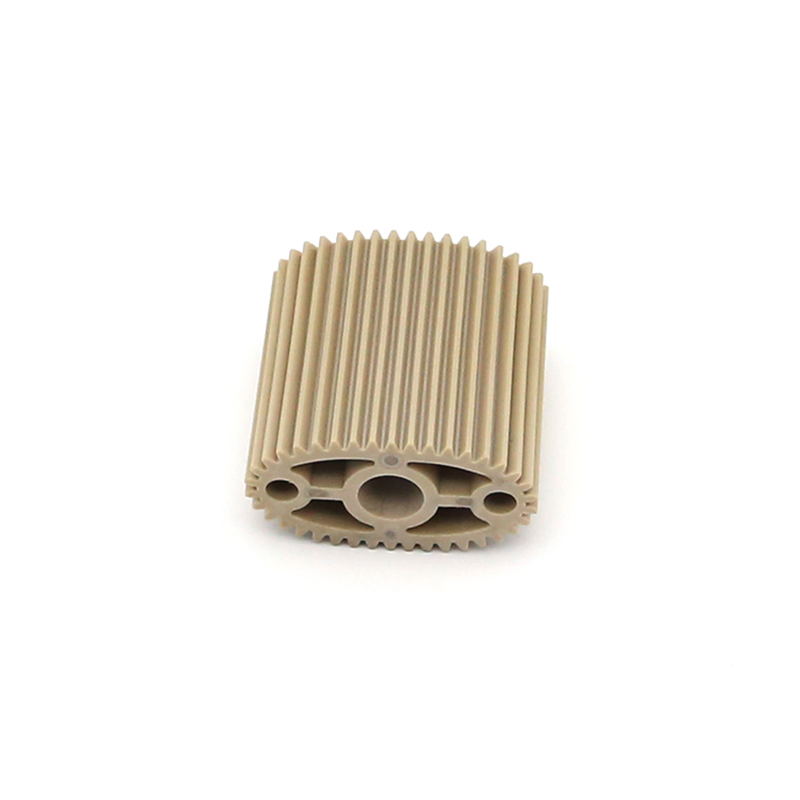

Bost Plastic Spur Gears — Reliable, High-Performance Engineering Gears

Product Overview

Bost plastic spur gears are engineered for reliable power transmission in a wide range of industrial applications. Manufactured by Bost, a professional and innovative high-tech green energy engineering plastics company, these gears combine advanced materials and precision molding to deliver consistent, quiet, and long-lasting performance.

Why Bost Plastic Spur Gears?

Our gears are made from specially modified engineering plastics that offer superior abrasion resistance, fatigue durability, and corrosion resistance. They reduce noise and vibration compared with metal gears, are lighter in weight, and require less lubrication—making them a practical choice for equipment that demands efficiency and low maintenance.

Key Features

Durability and Wear Resistance

Formulated for ultra-abrasion resistance and high fatigue life, Bost gears hold precise tooth geometry longer under load. This extends service intervals and reduces downtime.

Corrosion and Chemical Resistance

Ideal for humid or corrosive environments, the materials resist chemicals and moisture, ensuring steady operation even in challenging conditions.

High Temperature & Special Properties

Available in versions with higher temperature tolerance, transparency, flame retardancy, or enhanced toughness. We also offer conductive and thermally managed options for specialized needs.

Applications

Bost plastic spur gears are widely used in conveyors, printers, medical devices, HVAC systems, packaging machines, and low- to medium-load drives. Their low noise and lightweight properties make them suitable for equipment where quiet and efficient operation is essential.

Quality & Customization

Precision Manufacturing

Bost provides end-to-end capabilities: material R&D, mold design and manufacturing, mechanical processing, and assembly. We can produce custom sizes, tooth profiles, and composite steel-plastic solutions to meet specific performance requirements.

Trusted Support

With a strong technical team and rigorous quality control, Bost ensures every gear meets high standards. Contact us to discuss specifications, prototyping, and volume production.

Product Images

Question you may concern

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code