Send My Request

Injection Molding, Injection Molds, and Engineering Plastics: The "Three Musketeers of Plastics" Shaping Our Lives

Bost explores injection molding, precision injection mold design, and advanced engineering plastics—how these three musketeers shape products across industries. Learn applications, benefits and solutions for manufacturing excellence.

- Engineering Plastics: The "High-Quality Raw Material Bank" for Injection Molding

- Injection Molds: The "Precision Shapers" for Injection Molding

- Injection Molding: The "Magical Process" That Turns Raw Materials into Products

- Synergy of the Three: Shaping Countless Products for Industry and Daily Life

- Future Outlook: A More Eco-Friendly and Intelligent Development Direction

When you pick up a plastic toothbrush in the morning, grip a phone case during your commute, touch the car dashboard while driving, or even use the inner drum of your home washing machine—these ordinary daily items all come from a key manufacturing technology: injection molding. Supporting the realization of injection molding are two core "partners": engineering plastics as raw materials, and injection molds that determine the product shape. Like the "Three Musketeers of Plastics," these three work together to turn unremarkable plastic pellets into countless indispensable products in our lives. Today, let’s uncover their mysteries.

Engineering Plastics: The "High-Quality Raw Material Bank" for Injection Molding

When people hear the word "plastic," they often think of the fragility of disposable plastic bags, but engineering plastics are the "tough players" in the plastic family. The reason they can become the core raw material for injection molding lies in their performance far exceeding that of ordinary plastics: they can withstand temperatures above 100°C (some special engineering plastics can resist over 200°C). For example, parts around a car engine remain unsoftened and undeformed even in long-term high-temperature environments. They also have excellent mechanical strength—laptop casings made of engineering plastics are not easily broken if accidentally dropped. Additionally, most engineering plastics are resistant to chemical corrosion and will not be damaged when in contact with detergents, engine oil, or similar substances.

Common engineering plastics include polyamide (PA, commonly known as nylon), polycarbonate (PC), and polyoxymethylene (POM). For instance, car bumpers are often made of PA engineering plastics reinforced with glass fibers, which are both lightweight and impact-resistant; the shells of safety helmets we wear are mostly made of PC engineering plastics, which protect the head during accidental impacts; and the gears in printers frequently use POM engineering plastics due to their wear resistance and low deformation. It is these excellent properties of engineering plastics that provide "good materials" for injection molding. If ordinary plastics were used, they could never meet the industrial requirements for strength and heat resistance, and the products made via injection molding would not withstand daily use. It can be said that without high-quality engineering plastics, even the most advanced injection molding technology would be "like a skilled craftsman unable to cook without rice."

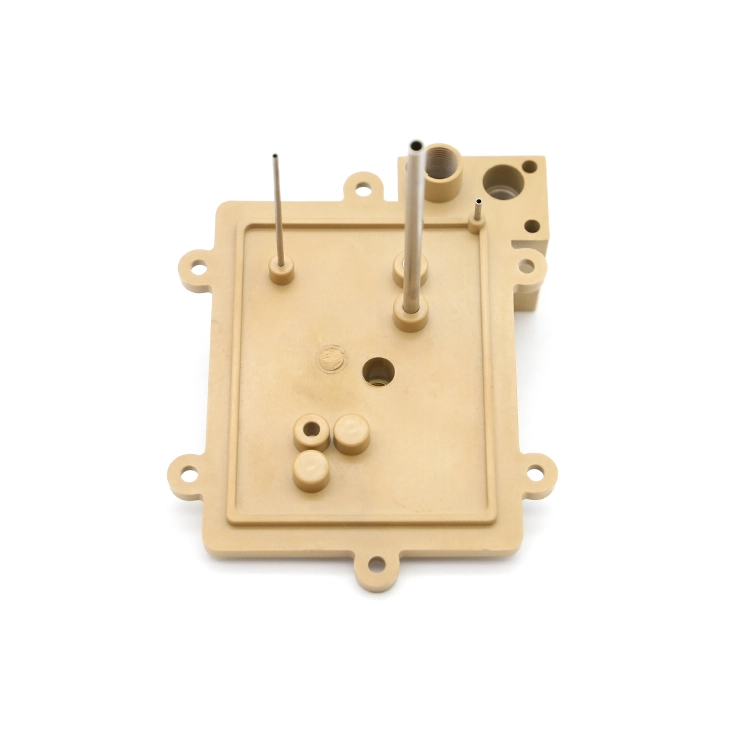

Injection Molds: The "Precision Shapers" for Injection Molding

With good engineering plastics, a "shaper" is still needed to give them specific shapes—and that is the injection mold. An injection mold is like a custom template that "dresses" engineering plastics; its core component is a "cavity" that is identical to the final product. Just like the groove of a cookie cutter, when molten engineering plastics enter the cavity, they cool and solidify into the corresponding shape. Beyond the cavity, an injection mold also includes key parts such as a gating system (which transports molten engineering plastics), a cooling system (which accelerates plastic solidification), and an ejection system (which pushes out the molded product).

The precision of an injection mold directly determines product quality. For example, the cavity tolerance of an injection mold for producing phone middle frames must be controlled within 0.02 millimeters (about 1/3 the diameter of a human hair); otherwise, the molded middle frame will not fit with other phone components. For injection molds used to make children’s toys, although the precision requirements are slightly lower, the cavity must have no sharp edges to avoid scratching children. Moreover, the service life of an injection mold is crucial: a high-quality injection mold can continuously produce hundreds of thousands or even millions of products, while a low-quality one may suffer from cavity wear and product deformation after only tens of thousands of productions. In the injection molding process, the design and manufacturing of injection molds play a "connecting" role—they must adapt to the fluidity of engineering plastics (for example, plastics with poor fluidity require thicker mold gates) and match the parameters of injection molding. Without a precise injection mold, even the best engineering plastics cannot become qualified products.

Injection Molding: The "Magical Process" That Turns Raw Materials into Products

When engineering plastics and injection molds are ready, injection molding becomes the core process that transforms "raw materials" into "products." This process is like an efficient "plastic magic trick," usually taking only tens of seconds to a few minutes, and can be divided into five steps:

1. Feeding and Melting: Engineering plastic pellets are poured into the hopper of an injection molding machine. The pellets enter a heating cylinder and are heated to 200-280°C (temperatures vary by engineering plastic—for example, PC requires around 250°C, while PA needs about 220°C), melting into a flowing "plastic melt."

2. Injection and Filling: The screw of the injection molding machine, like squeezing cream, rapidly presses the plastic melt into the cavity of the injection mold to ensure every corner is filled.

3. Pressure Holding and Compensation: The screw maintains a certain pressure to prevent bubbles or material shortages caused by the cooling and shrinkage of the plastic melt.

4. Cooling and Setting: The cooling system of the injection mold uses cold water to lower the temperature, quickly solidifying the plastic melt in the cavity into a solid.

5. Mold Opening and Part Removal: The mold opens automatically, and the ejection system pushes out the molded product—completing a finished injection-molded product.

In the injection molding process, the coordination between engineering plastics, injection molds, and process parameters is critical. For example, if engineering plastics have poor fluidity, the injection temperature or pressure needs to be increased; uneven cooling of the injection mold will cause product deformation; and insufficient pressure-holding time may lead to "shrinkage" marks on the product. Take the casing of a home appliance remote control as an example: first, a tough ABS engineering plastic is selected; then, the injection mold is designed according to the fluidity of ABS to ensure precise key grooves; finally, the injection molding parameters are adjusted—heating temperature of 230°C, injection pressure of 70MPa, and cooling time of 25 seconds. Only through these steps can a remote control casing with a smooth surface and flexible buttons be produced.

Synergy of the Three: Shaping Countless Products for Industry and Daily Life

In fact, injection molding, injection molds, and engineering plastics form an "interdependent, indispensable" whole. For example, when producing plastic parts for car engines: first, PPS engineering plastic is selected based on the requirements of "high temperature resistance and engine oil corrosion resistance"; then, the injection mold is designed according to the shrinkage rate of PPS (it shrinks after cooling), with the cavity size 1.5% larger than the final product to offset shrinkage; finally, the injection molding temperature is adjusted to 300°C to ensure PPS is fully melted without decomposition. It is this synergy that allows plastic parts to work stably in the harsh environment of the engine.

Another example is the casing of medical syringes: non-toxic, high-temperature sterilization-resistant PP engineering plastic must be used; the injection mold must meet medical-grade precision to avoid tiny gaps that trap dirt; and the "flash-free" process must be adopted during injection molding to ensure smooth casing edges and prevent scratches on medical staff or patients. From industrial parts to daily necessities, from medical equipment to electronic devices, the synergy of these "Three Musketeers of Plastics" is constantly expanding the application boundaries of plastic products.

Future Outlook: A More Eco-Friendly and Intelligent Development Direction

With the advancement of technology, injection molding, injection molds, and engineering plastics continue to evolve. In the field of engineering plastics, "bio-based engineering plastics" are emerging—plastics made from corn starch and plant fibers not only meet performance standards but also biodegrade naturally, reducing environmental pollution. In terms of injection molds, 3D printing technology is being used for rapid mold manufacturing; a mold that originally took 30 days to make can now be completed in 10 days, greatly shortening the R&D cycle. Injection molding is moving toward "intelligence": factories use sensors to monitor temperature and pressure in real time, and once an abnormality occurs, the AI system immediately adjusts parameters, increasing the product qualification rate to over 99%.

In the future, we may use car parts made from recycled engineering plastics, personalized phone cases mass-produced quickly with 3D-printed injection molds, or ultra-thin, ultra-light electronic device casings produced via intelligent injection molding. These "Three Musketeers of Plastics" will not only make products better and more eco-friendly but also continue to transform our lives and industrial production methods.

From toothbrushes to cars, from home appliances to medical equipment, injection molding, injection molds, and engineering plastics have long integrated into every corner of life. Although they seem like industrial technologies, they use "plastic magic" to create a convenient and comfortable modern life for us. With continuous technological breakthroughs, these three will create more possibilities, enabling plastic products to move further toward "high performance" and "sustainability."

Guangzhou Bost Rubber & Plastic Technology Co,ltd, (BOST) focuses on deeply engaging in the plastics industry and is capable of providing you with professional plastic optimization and solutions.

Recommended for you

FAQ

FAQs

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

You may also like

Customized Plastic Injection molding -faster delivery and economical

BOST Injection molding -Customized and OEM Supplier

Injection molding parts-Precision plastic parts custom

Leave a Message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code