Send My Request

Bost Injection-Molded Black POM Wear-Resistant Spacing

Bost Injection-Molded Black POM Wear-Resistant Spacing

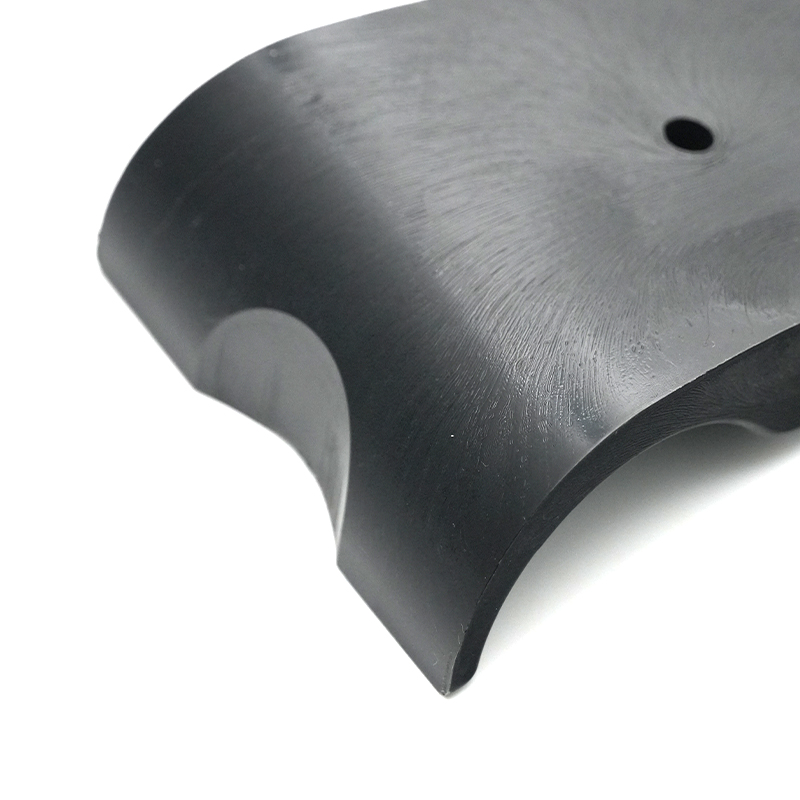

Bost presents a high-performance injection-molded black POM (polyoxymethylene) wear-resistant spacing designed for demanding industrial and mechanical applications. Backed by Bost’s experience in advanced engineering plastics, this spacer combines precision molding with robust material properties to deliver reliable, long-lasting components.

Why choose Bost Black POM Spacer?

- Wear-resistant: Superior abrasion resistance for long service life under repeated motion.

- Low friction: Smooth surface reduces friction, noise and energy loss in moving parts.

- Corrosion and chemical resistance: Performs well in contact with common oils and many chemicals.

- Dimensional stability: Precision injection molding ensures consistent tolerances and fit.

- High fatigue resistance: Maintains shape and function after repeated load cycles.

Key features

Manufactured from specially formulated POM, the spacer offers enhanced toughness and controlled hardness. Bost’s production process emphasizes quality control, ensuring each part meets strict standards for surface finish, concentricity and size accuracy. The black coloring provides UV and aesthetic benefits for visible applications.

Applications

This spacer is suitable for a wide range of uses including:

- Automotive assemblies and interior mechanisms

- Industrial machinery and conveyors

- Electrical housings and mechanical fittings

- Consumer appliances and precision devices

Installation and maintenance

Designed for easy installation, the spacer fits common shaft and bore sizes with minimal adjustment. Routine inspection and cleaning are recommended to remove debris and check wear; replacement intervals depend on operating conditions but are extended by POM’s wear-resistant properties.

About Bost

Bost is a professional and innovative green-energy engineering plastics manufacturer specializing in R&D, production and sales. The company focuses on high-quality special engineering plastics and modification technologies—offering anti-scar, corrosion-resistant, fatigue-durable and abrasion-resistant solutions. Bost’s experienced R&D and production teams ensure products that are reliable, precisely made and backed by solid technical support.

Choose Bost’s injection-molded black POM wear-resistant spacing for dependable performance, reduced downtime and confident long-term use.

Product Images

Question you may concern

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

If you have another questions, please feel free to contact us.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code