Bost leads among Insert Molding Companies, specializing in advanced Insert Molding Technology. Our core capabilities ensure seamless integration of inserts and plastics for durable, precise components. Trust Bost for expert solutions in efficient, high-quality insert molding services.

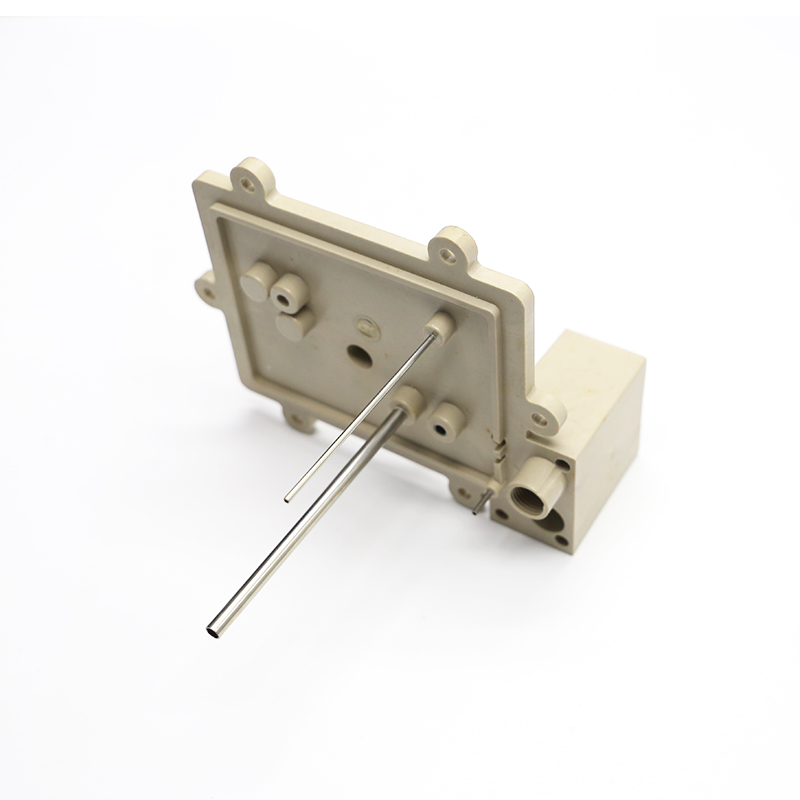

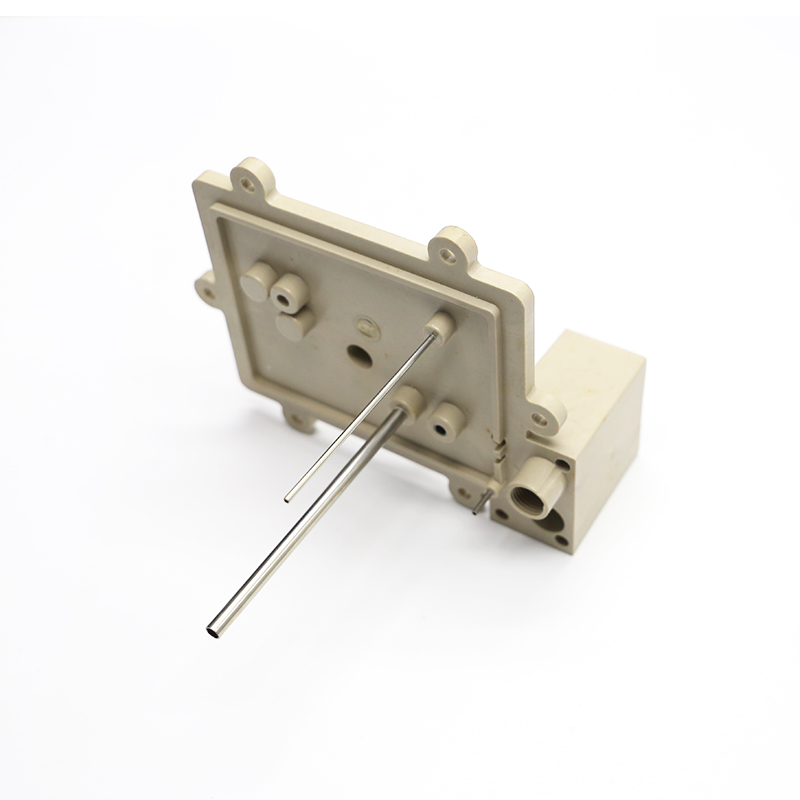

In daily life, household appliance terminal blocks with metal threads, automotive sensor brackets with built-in copper pins, and medical connectors with metal contacts—these composite parts of "plastic + inserts" are all precision-manufactured by insert molding companies. Insert molding technology accurately integrates inserts such as metal and ceramics with plastics, enabling parts to have both the high strength of inserts and the lightweight, easy-forming characteristics of plastics. Insert molding companies are the core carriers for the implementation of this technology. They need to have full-chain technical control capabilities.

BOST is a professional injection mold company, and as a long-term cooperative partner of senior insert molding companies, it has provided mature insert molding solutions for home appliances, automotive, medical and other industries.

Material compatibility and pretreatment are the basic core capabilities of insert molding companies. The compatibility between inserts and plastics directly determines the bonding strength and service life of parts, and material requirements vary significantly across industries: the home appliance industry commonly uses "brass inserts + PP plastic" to balance conductivity and temperature resistance; the automotive industry prefers "stainless steel inserts + PA66 plastic" to meet the needs of impact resistance and extreme temperature resistance; the medical industry selects "titanium alloy inserts + medical PC plastic" to meet biocompatibility requirements. In addition, inserts need to undergo pretreatment (such as grinding and degreasing) to enhance bonding with plastics. BOST is a professional injection mold company, and its technical team conducts special tests for different material combinations: for example, when customizing insert connectors for a medical enterprise, BOST performs surface micro-roughening treatment on titanium alloy inserts, selects suitable medical PC plastics, and ensures firm bonding through compatibility tests, with no loosening after multiple disinfections, meeting medical safety standards.

Customized mold design is the core competitiveness of insert molding companies and also the professional advantage of BOST. The core difference between insert molding molds and ordinary injection molds lies in the need to achieve precise positioning of inserts and uniform wrapping of plastics. Unreasonable mold positioning structure is likely to cause insert displacement and uneven plastic filling; improper layout of vent grooves will generate bubbles at the junction of inserts and plastics, affecting part strength. BOST is a professional injection mold company that customizes exclusive molds for insert molding characteristics: adopting a "multi-station positioning pin + annular vent groove" structure to ensure inserts are fixed without displacement; optimizing flow path trajectory through simulation software to ensure uniform wrapping of inserts by plastics. For example, when designing a mold for a "four-pin copper insert plastic interface" for an electronic enterprise, BOST controlled the insert spacing error within 0.02mm through this design, with no gaps in plastic wrapping, perfectly adapting to the precision docking needs of electronic equipment.

Process parameter optimization is a key link for insert molding companies to ensure product quality. Insert molding requires strict control of temperature, pressure and injection speed: excessively high plastic melting temperature is likely to cause insert deformation, and insufficient pressure will lead to incomplete plastic filling. BOST is a professional injection mold company with a complete database of insert molding process parameters, which can accurately match schemes according to different material combinations: when producing automotive sensor insert brackets, the barrel temperature is controlled in sections (230℃ at the front section, 240℃ in the middle section, 220℃ at the rear section), and the "low-speed filling + high-speed pressure holding" mode is adopted to avoid insert displacement; when processing thin-walled insert parts, the injection speed is reduced to ensure uniform plastic wrapping without bubbles. An automotive component enterprise was once troubled by the low qualification rate of insert molding parts. After BOST's intervention, by adjusting process parameters and optimizing the mold vent structure, the product qualification rate was increased from 82% to 99.3%, efficiently solving the production problem.

For insert molding companies, full-process service capability is the core support to adapt to the needs of multiple industries. From early material selection and insert pretreatment, to mid-term mold design and process debugging, to later mass production and quality inspection, each link needs precise control. As a professional injection mold company, BOST, with years of experience in the insert molding field, can provide customers with one-stop solutions. Whether it is mass production of daily consumer goods or customized needs of high-end industrial accessories, it can achieve efficient implementation with technical strength and become a reliable partner in the insert molding field.

Scan QR Code

Scan QR Code