Choosing between ABS plastic vs PVC? Don’t risk project failure with the wrong material. Our 10-year industry expert breaks down impact strength, UV protection, and ABS plastic molding costs. Discover how specialized ABS plastic manufacturers can cut your waste by 20% using custom ABS plastic sheet 4x8 solutions. Read more for a free material optimization analysis and secure your high-performance supply chain today!

Introduction

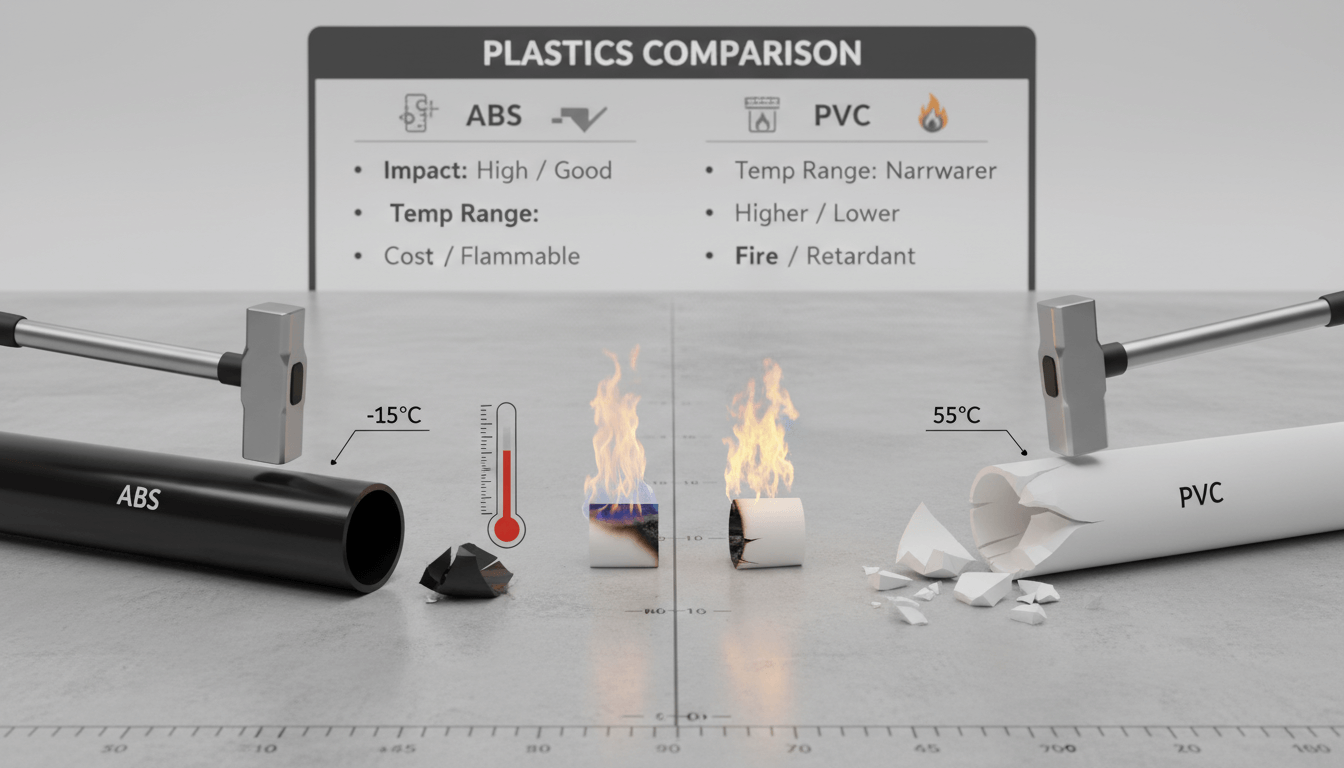

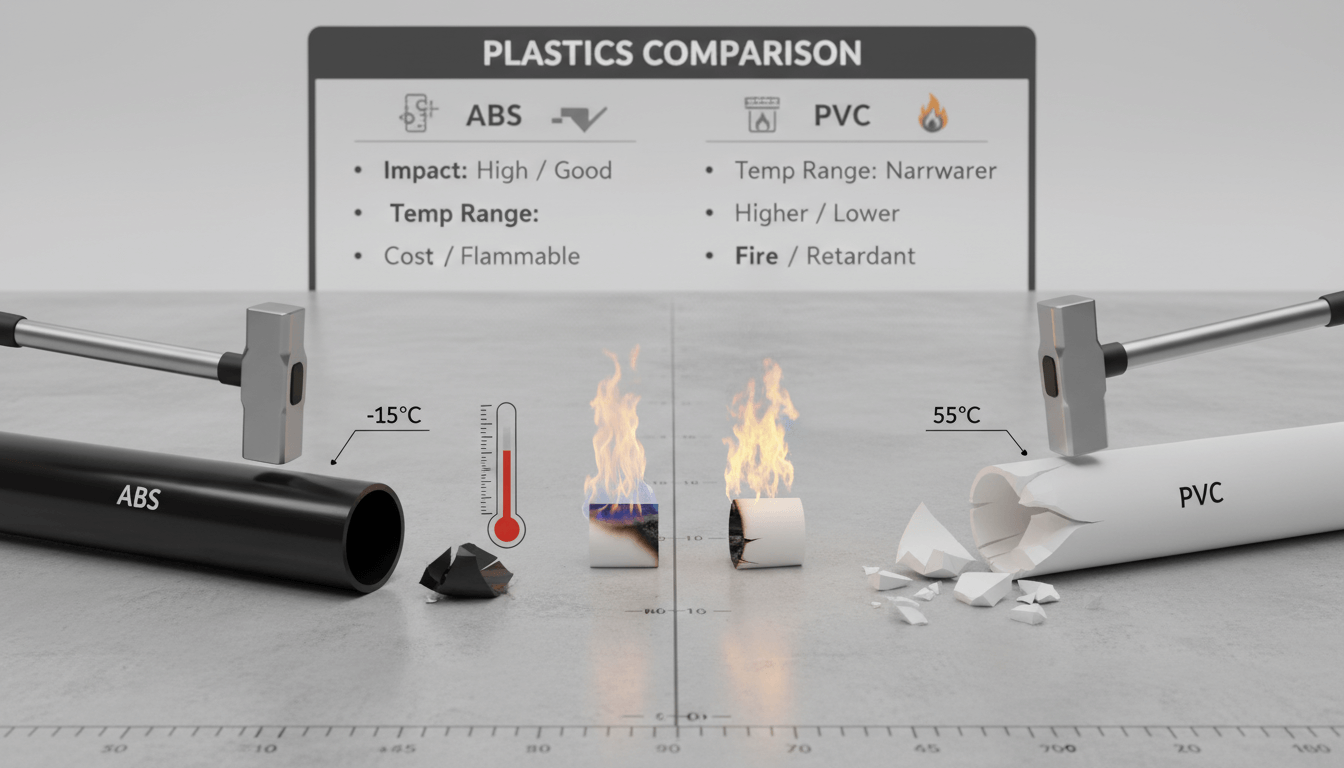

In the world of high performance plastics, two names consistently dominate the conversation: PVC (polyvinyl chloride) and ABS (acrylonitrile butadiene styrene). Both are versatile, cost-effective, and widely available. However, choosing the wrong one can lead to brittle failures, chemical degradation, or manufacturing bottlenecks.

As the global market for engineering plastic shifts toward more specialized applications, understanding the nuanced differences between ABS plastic vs PVC is critical for any B2B buyer.

What is PVC material?

PVC, or Polyvinyl Chloride, is one of the most widely produced synthetic plastic polymers. It comes in two basic forms: rigid (RPVC) and flexible. In the industrial world, PVC is prized for its exceptional chemical resistance and inherent flame retardancy.

From a manufacturing standpoint, plastic PVC is highly stable. It handles exposure to acids, alkalis, and many corrosive chemicals better than most mid-range polymers. For buyers, this means a lower total cost of ownership in environments where chemical exposure is a daily reality.

What is PVC used for?

PVC is the "workhorse" of the construction and medical industries. Because of its resistance to corrosion and biological growth, it is the primary choice for potable water systems and medical-grade tubing. In the industrial sector, it is frequently used for:

-

Electrical cable insulation.

-

Chemical storage tanks and liners.

-

Rigid panels for hygienic wall cladding.

What is ABS plastic?

If PVC is the "workhorse," then ABS is the "athlete" of the engineering plastic world. ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. This specific chemistry provides a "best of all worlds" scenario: the strength of acrylonitrile, the impact resistance of butadiene rubber, and the processability of styrene.

Top-tier ABS plastic manufacturers focus on the balance of these three components to create grades that can withstand significant physical abuse without cracking.

What is ABS plastic used for?

ABS is the go-to material for products that require a high-quality aesthetic finish combined with structural toughness, and its popularity is largely driven by the injection molding advantages of ABS material, including excellent flowability, dimensional stability, and cost-effective mass production. Its high impact resistance at low temperatures makes it superior to PVC in colder climates. Common applications include:

-

ABS plastic molding for consumer electronics and appliance housings.

-

Black ABS plastic sheets for heavy-duty industrial protective covers.

-

Laser engraving ABS plastic for durable signage, control panels, and identification tags.

-

-

Is ABS and PVC pipe compatible?

One of the most frequent technical inquiries we receive as an engineering plastic leader is whether these two systems can be mixed. The short answer: Technically yes, but with strict caveats.

Because ABS plastic vs PVC involves two entirely different chemical structures, they cannot be "solvent welded" together using standard single-material glues. Standard PVC cement will not bond to ABS, and vice versa. To ensure compatibility in a professional system:

-

Transition Cement: You must use a specialized transition cement (ASTM D3138) specifically designed to bond the two dissimilar plastics.

-

Mechanical Couplings: In many industrial codes, the preferred method is using a shielded mechanical coupling rather than a chemical bond.

-

Pressure Limitations: Mixing materials is generally restricted to non-pressure DWV (drain-waste-vent) systems. For pressurized lines, it is always recommended to stick to one material throughout to avoid failure points.

How to recycle PVC and ABS plastic

Sustainability is no longer an "extra"—it's a procurement requirement.

-

Recycling ABS: ABS is a thermoplastic, meaning it can be melted and reshaped multiple times. Most ABS plastic manufacturers now offer "regrind" services where production scrap is fed back into the ABS plastic molding process. This reduces waste and lowers the carbon footprint of your project.

-

Recycling PVC: PVC is more challenging to recycle due to its high chlorine content. However, specialized recycling programs can mechanically process PVC scrap into "second-life" products like floor mats or speed bumps.

When choosing between ABS plastic vs PVC, consider the end-of-life cycle. If circularity is a KPI for your company, ABS generally offers a more straightforward recycling path.

When should you use PVC, and when should you use ABS?

This is the most common question I receive. The choice often boils down to the specific environment of the installation.

Choose PVC if:

-

Chemical Resistance is a Priority: If the component will be in contact with strong acids or household bleach.

-

Fire Safety is Critical: PVC is naturally self-extinguishing.

-

Cost is the primary driver: for high-volume, low-stress applications, PVC is typically more budget-friendly.

Choose ABS if:

-

Impact Strength Is Needed: If your component will be dropped, kicked, or pressurized.

-

Plumbing Specifics: ABS plastic plumbing fittings are easier to install (one-step solvent weld) and perform better in underground high-impact scenarios compared to PVC.

-

Precision Machining: If you need laser engraving of ABS plastic for clear, high-contrast markings.

-

Temperature Swings: ABS maintains its integrity in cold weather, whereas PVC can become brittle.

| Feature |

PVC (Polyvinyl Chloride) |

ABS (Acrylonitrile Butadiene Styrene) |

| Impact Resistance |

Moderate |

High |

| Joining Method |

Two-step (Primer + Cement) |

One-step (Solvent Cement) |

| Cold Weather |

Brittle |

Excellent |

| Chemical Resistance |

High |

Moderate |

Alternatives to PVC and ABS

While ABS plastic vs PVC is the main debate, sometimes a project requires high performance plastics that go beyond standard specs:

-

Polycarbonate (PC): For when you need transparency plus extreme impact resistance.

-

High-Density Polyethylene (HDPE): For superior moisture resistance and food-grade safety.

-

Nylon (PA): Best for high-friction mechanical parts like gears.

Conclusion

Choosing between ABS plastic vs PVC isn't about which plastic is "better"—it's about which is right for your environment. If you need a cost-effective, chemically resistant solution for indoor plumbing, plastic PVC is your winner. However, if you are designing industrial equipment that requires high impact strength, easy ABS plastic molding, and the ability to handle laser engraving ABS plastic, then ABS is the superior investment.

Don't let material failure be the reason your project goes over budget. Partner with experienced ABS plastic manufacturers who understand the technical demands of your industry.

FAQs

Can I use ABS plastic fittings with PVC pipes?

It is generally not recommended to mix them directly because the solvent cements are different. However, specialized transition fittings are available if you must connect ABS plastic plumbing fittings to PVC lines.

Is black ABS plastic UV resistant?

Standard black ABS plastic has some inherent UV resistance due to the carbon black pigment, but for long-term outdoor use, you should request a UV-stabilized grade from your manufacturer.

Which is easier to install: ABS or PVC?

Most contractors prefer ABS plastic plumbing fittings because they require a one-step solvent process, whereas PVC requires a purple primer and then the cement.

Is ABS plastic molding more expensive than PVC molding?

Generally, yes. The raw ABS plastic pellets are slightly more expensive, and the ABS plastic molding process requires tighter temperature control, but the result is a much tougher part.

Why choose laser engraving ABS plastic over PVC?

PVC releases toxic chlorine gas when laser cut or engraved, which is dangerous for operators and corrosive to the machine. ABS is much safer and cleaner for laser engraving abs plastic processing.

How do you help reduce unit costs and material waste for bulk purchases?

This is a very practical concern for any procurement professional. As experienced ABS plastic manufacturers, we don't just provide the standard 4x8 ABS plastic sheet 4x8, we also offer custom-sized precision cutting based on your specific part layout. By optimizing the ABS plastic pellets formulation for your specific needs and minimizing scrap during secondary processing, we can typically reduce procurement costs by 10% to 20% for our bulk clients. You are welcome to send us your CAD drawings or technical specifications, and we will perform a complimentary "Material Utilization & Cost-Efficiency Analysis" for your project.

Can you provide technical selection support for complex industrial environments?

Absolutely. In the engineering plastic industry, a material selection error can lead to catastrophic failure and expensive downtime. Our technical team has over a decade of experience in high performance plastics applications. We can provide a professional abs plastic vs pvc performance comparison report tailored to your specific chemical exposure list, pressure requirements, and temperature ranges. If you are currently facing a selection dilemma, please click [Contact Us] to schedule a 1-on-1 video consultation with one of our senior technical experts.

Scan QR Code

Scan QR Code