Send My Request

Bost China Plastic Spur Gears — Precision, Durability, Reliability

Product Overview

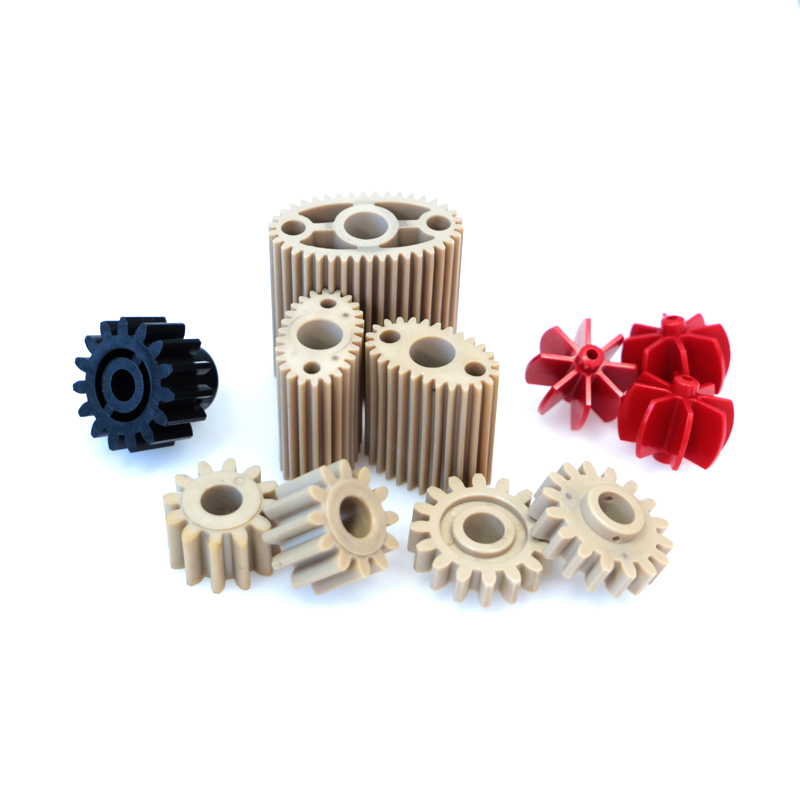

Bost China plastic spur gears are designed for reliable power transmission in a wide range of applications. Made from advanced engineering plastics, these gears combine strength, low friction, and excellent wear resistance. They deliver smooth, low-noise operation and require little or no lubrication, making them ideal for machines where cleanliness and maintenance reduction matter.

Key Features

- High wear and abrasion resistance for long service life

- Low noise and vibration for quieter operation

- Good chemical and corrosion resistance for harsh environments

- Lightweight and low inertia, improving energy efficiency

- Precision tooth profiles for accurate meshing and minimal backlash

- Available in common engineering plastics (PA, POM) and custom blends

Materials and Quality

Our spur gears are produced from modified engineering plastics developed by Bost’s R&D team. Materials are selected and modified to enhance toughness, abrasion resistance, temperature performance, and dimensional stability. Each batch undergoes strict quality control and precision machining to ensure consistent gear geometry and reliable performance.

Typical Applications

Bost plastic spur gears suit many industries, including packaging, food processing, medical devices, office equipment, conveyor systems, and light machinery. They are especially useful where corrosion resistance, low noise, and reduced maintenance are priorities.

Why Choose Bost

Bost is a professional, innovative, high-tech manufacturer focused on green energy engineering plastics. We specialize in developing special property plastics—anti-scar, corrosion-resistant, high-temperature, flame retardant, and conductive grades. Our strong production capability, toolmaking, and material modification expertise ensure each gear meets performance and longevity expectations.

Customization and Support

We offer custom sizes, tooth profiles, and material grades to match your design needs. Technical support is available for material selection, gear design, and production planning. Fast delivery and consistent after-sales service give you confidence in every order.

Contact Bost today to discuss your spur gear requirements and get a tailored solution that balances performance, cost, and durability.

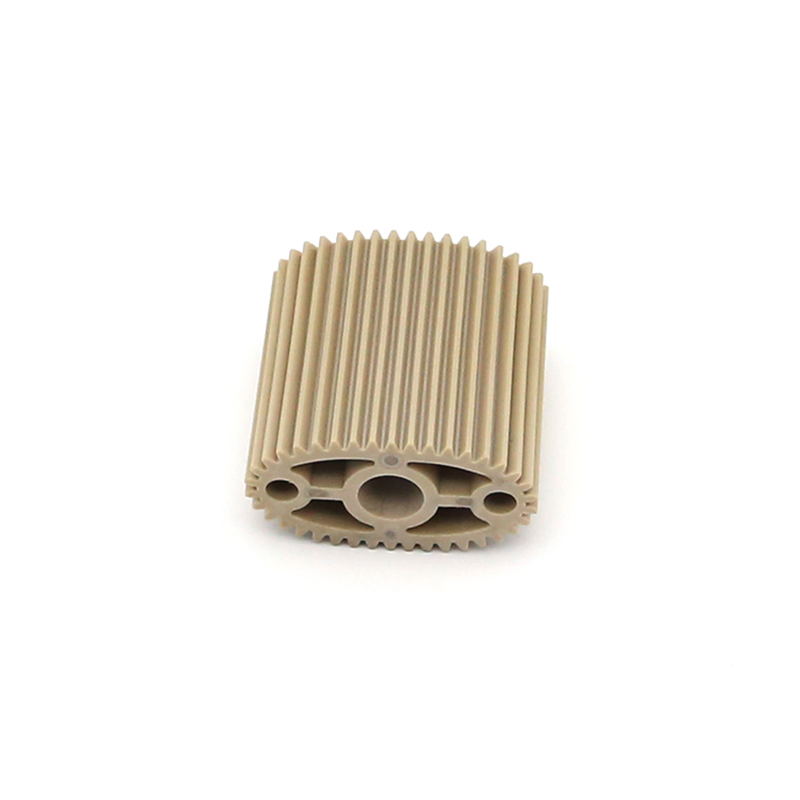

Detailed display

Frequently Asked Questions

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code