Send My Request

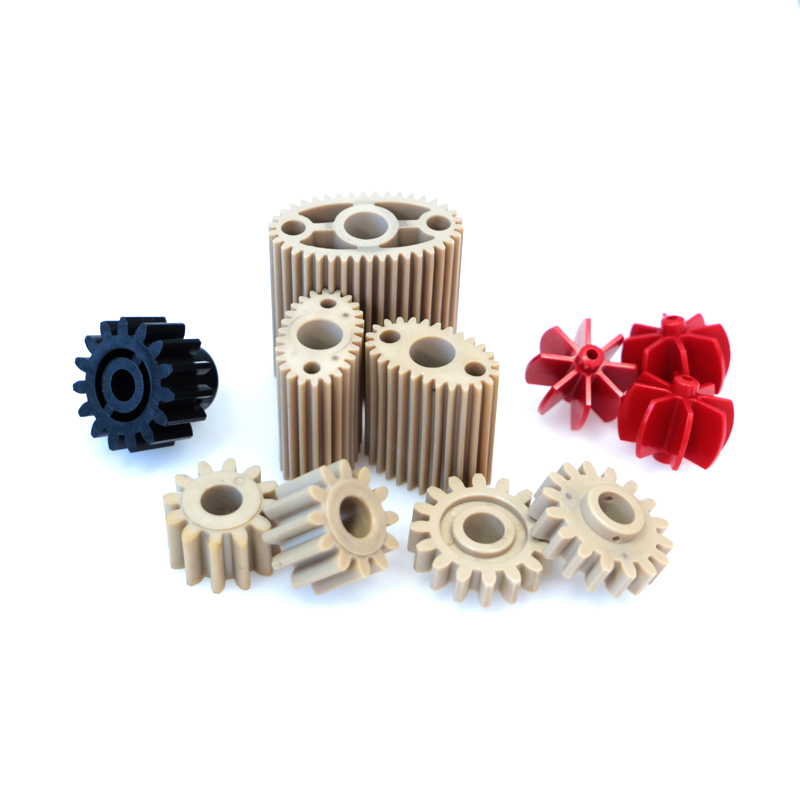

Bost Custom Plastic Spur Gears

Custom Plastic Spur Gears by Bost

Bost offers custom plastic spur gears engineered for durable, quiet, and cost-effective power transmission. As a professional high-tech green energy engineering plastics manufacturer, Bost combines advanced materials, mold design and precision processing to deliver gears that meet your exact specifications.

High Performance Materials

We use specially modified engineering plastics that provide excellent wear resistance, corrosion protection, fatigue life and thermal stability. Our materials can be toughened, flame-retardant, conductive or optimized for low friction — allowing gears to run quietly and last longer than standard plastics in many environments.

Tailored to Your Needs

Bost supports full customization: tooth profile, module, pitch diameter, thickness, bore, keyways, inserts and surface finishes. We also do steel-plastic and plastic-rubber combinations when hybrid strength or vibration damping is required. Quick prototyping and precise mold tooling ensure your parts fit and perform from the first run.

Practical Benefits

- Lightweight and low-noise operation compared to metal gears

- Corrosion resistant — ideal for humid or chemical exposure

- Lower maintenance and longer service intervals

- Cost-effective for small to large production runs

Applications

Our custom spur gears suit a wide range of industries: industrial machinery, automotive systems, consumer appliances, robotics, medical devices, and renewable energy equipment. Bost’s knowledge of engineering plastics makes these gears a reliable choice where performance and longevity matter.

Quality, Support and Fast Delivery

Bost combines strong R&D and production capabilities with rigorous quality checks. We provide engineering support from design to final inspection and offer flexible lead times to match project schedules. Choosing Bost means partnering with a manufacturer focused on innovation, consistency and customer satisfaction.

Contact Bost today to discuss your custom plastic spur gear requirements and get a solution designed for real-world performance.

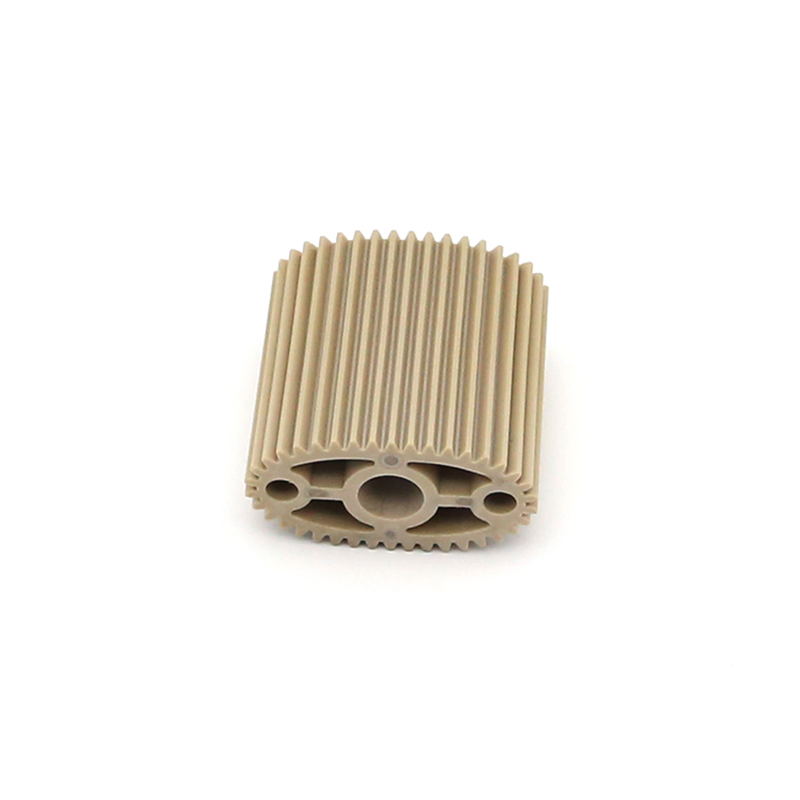

Detailed display

FAQ

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code