Send My Request

Bost Custom Plastic Spur Gears — Reliable Engineering Plastics

About Bost Custom Plastic Spur Gears

Bost is a professional, innovative high-tech manufacturer of green energy engineering plastics. Our custom plastic spur gears are designed and produced to meet demanding performance needs while keeping costs, weight and maintenance low. We focus on quality, fast delivery and clear communication so customers feel valued at every step.

Key Benefits

High Durability and Wear Resistance

Made from specially modified engineering plastics, our spur gears resist abrasion, scuffing and fatigue. This extends service life and reduces replacement frequency, saving time and money.

Low Noise and Smooth Operation

Plastic materials naturally damp vibration and reduce gear noise. This makes our gears ideal for applications where quiet operation matters, such as robotics, office equipment and consumer electronics.

Corrosion and Chemical Resistance

Bost gears withstand corrosive environments better than many metals. They are suited for food processing, chemical handling and coastal applications where moisture and chemicals are a concern.

Applications

Our custom spur gears serve a wide range of industries: industrial machinery, automotive assemblies, conveyors, automation systems, medical devices and household appliances. We provide gears in sheets, rods and finished machined parts to match installation needs.

Customization and Quality

Tailored to Your Needs

We offer custom tooth profiles, sizes, materials and surface finishes. Whether you need high-temperature resistant, flame-retardant, conductive or extra-tough formulations, Bost’s R&D and production teams deliver practical solutions.

Strict Manufacturing Controls

From mold design to precision machining and final inspection, we control every step to ensure dimensional accuracy and consistent performance. We also provide technical support to help choose the right material and design for your application.

Why Choose Bost

Bost combines advanced plastics modification expertise with strong production capacity. Choosing our custom plastic spur gears means getting a durable, cost-effective and quieter alternative to metal gears — backed by responsive service and proven technical know-how.

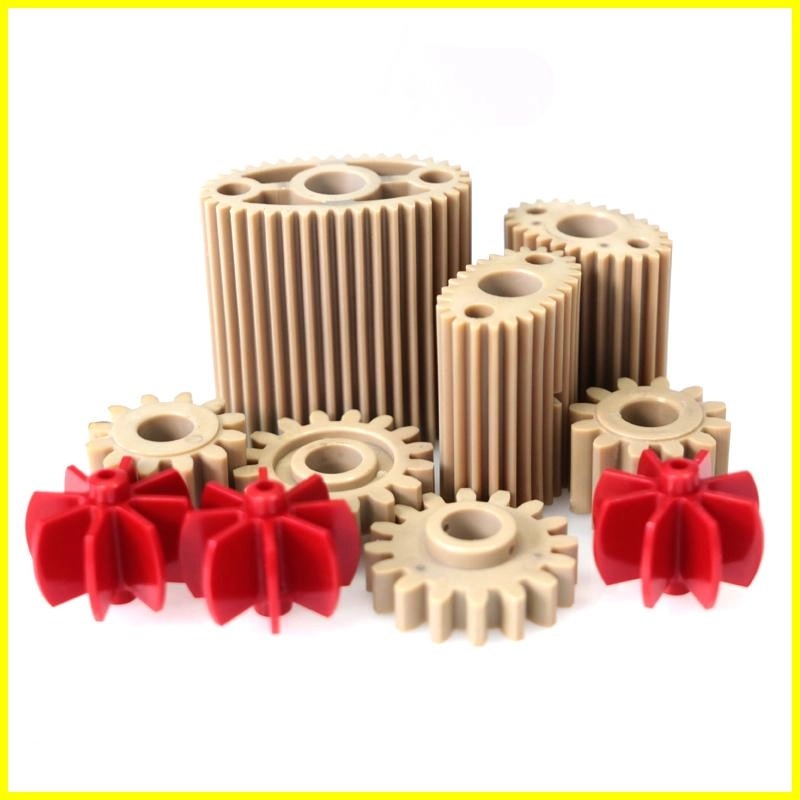

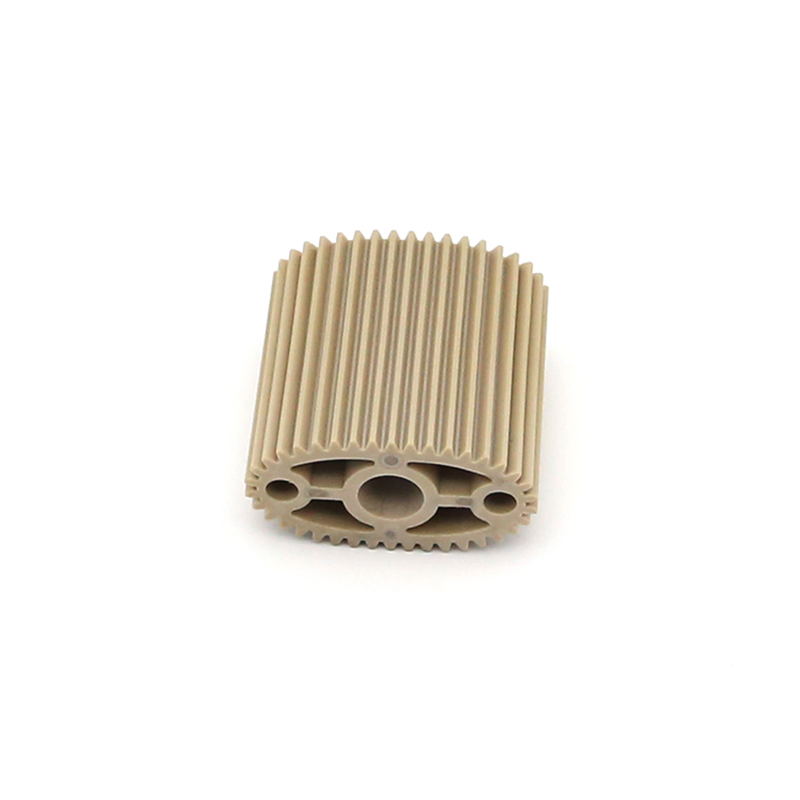

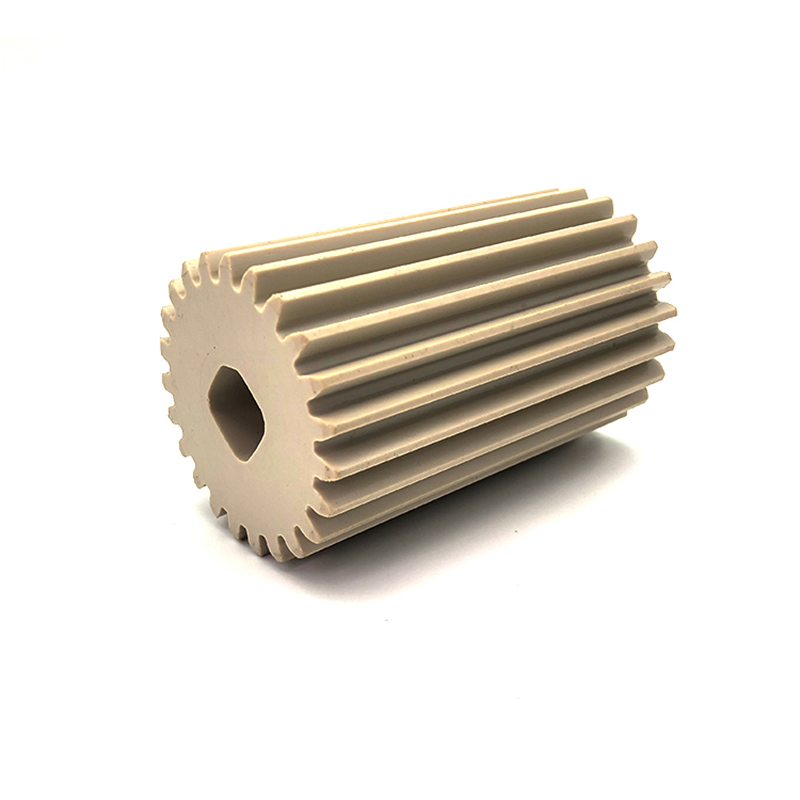

Picture Show

Question you may concern

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code