Send My Request

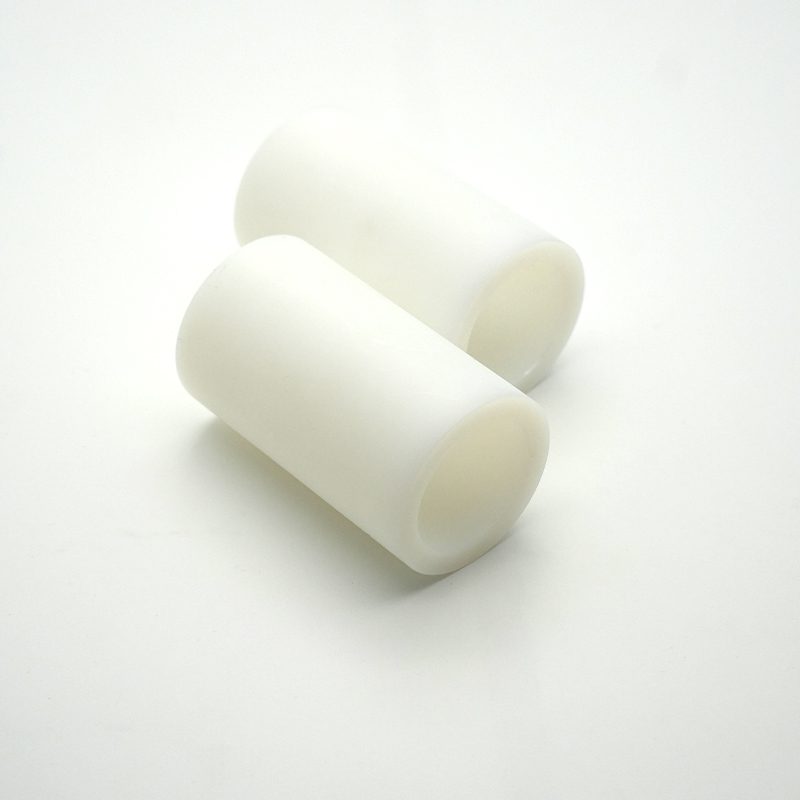

Impact-Resistant Stable Fitting

Impact-Resistant Stable Fitting by Bost

Bost brings a new level of reliability with the Impact-Resistant Stable Fitting. Made from advanced engineering plastics, this fitting combines superior impact resistance, dimensional stability, and long-term durability. It is designed for demanding industrial, construction, and green energy applications where secure, low-maintenance connections are essential.

Why choose Bost Stable Fitting?

- Exceptional impact resistance — reduces breakage and downtime.

- Stable fitting geometry — maintains tight tolerances and a secure fit over time.

- High abrasion and corrosion resistance — performs in harsh environments.

- Excellent fatigue life — stays reliable under repeated load cycles.

- High-temperature and conductive options — for specialized thermal needs.

Key advantages

Unlike ordinary fittings, Bost's product uses modified engineering plastics that add toughening, flame retardancy, and thermal conductivity where needed. The result is a fitting that reduces installation effort, limits maintenance costs, and extends service life. Its smooth surfaces resist scarring and buildup, while precision molding ensures a consistent, stable fit for fast assembly.

Applications

Ideal for renewable energy systems, machinery components, pipeline connectors, protective housings, and equipment where vibration, impact, or temperature changes occur. Bost fittings are especially valuable where steel-plastic combinations are used to balance strength and weight.

About Bost

Bost is a professional and innovative high-tech green energy engineering plastics manufacturer focused on R&D, production, and sales. With strong capabilities in plastics modification, mold design, and combined steel-plastic solutions, Bost delivers High Quality products and customer-focused service.

Buy with confidence

Choose Bost Impact-Resistant Stable Fitting for reliable performance, longer life, and lower total cost of ownership. Contact us to find the right specification for your project and to request samples or technical data.

Detailed display

Q&A

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code