Send My Request

Bost Low Temperature & Chemical Resistance Engineering Plastics

Bost Low Temperature & Chemical Resistance Engineering Plastics

Bost offers advanced engineering plastics engineered to perform in extreme cold and aggressive chemical environments. Backed by a professional R&D team and high-tech production, our materials combine low-temperature toughness with outstanding chemical resistance to protect parts and extend service life.

Key Features

- Excellent low-temperature toughness—remains tough and dimensionally stable at sub-zero temperatures.

- Superior chemical resistance—resists acids, alkalis, solvents and common industrial fluids.

- High wear and fatigue resistance—reduces maintenance and replacement costs.

- Good machinability—sheets, rods and custom-molded parts are easy to process and install.

- Optional enhancements—flame retardancy, conductivity, and surface toughening available on request.

Benefits for Your Products

Choose Bost plastics to reduce downtime and improve reliability. Our materials keep seals, bearings, gears, and insulation performing in cryogenic storage, outdoor cold climates, and chemical processing lines. The combination of low friction and high corrosion resistance means smoother operation and longer life.

Typical Applications

- Cryogenic equipment and pipelines

- Chemical tanks, valves and fittings

- Cold-climate automotive and transportation parts

- Outdoor equipment exposed to de-icers and solvents

- Seals, gaskets, bearings and wear pads in corrosive environments

Why Bost?

Bost is a professional and innovative high-tech green energy engineering plastics manufacturer. We focus on R&D, production and sales of special engineering plastics with unique properties—anti-scar, super corrosion-resistant, fatigue-durable, and more. Our experienced team supports mold design, mechanical processing and tailored modifications to meet your exact needs.

Whether you need standard sheets and rods or custom molded parts with enhanced properties, Bost delivers reliable materials that perform where ordinary plastics fail. Contact us to find the right low-temperature, chemical-resistant solution for your project.

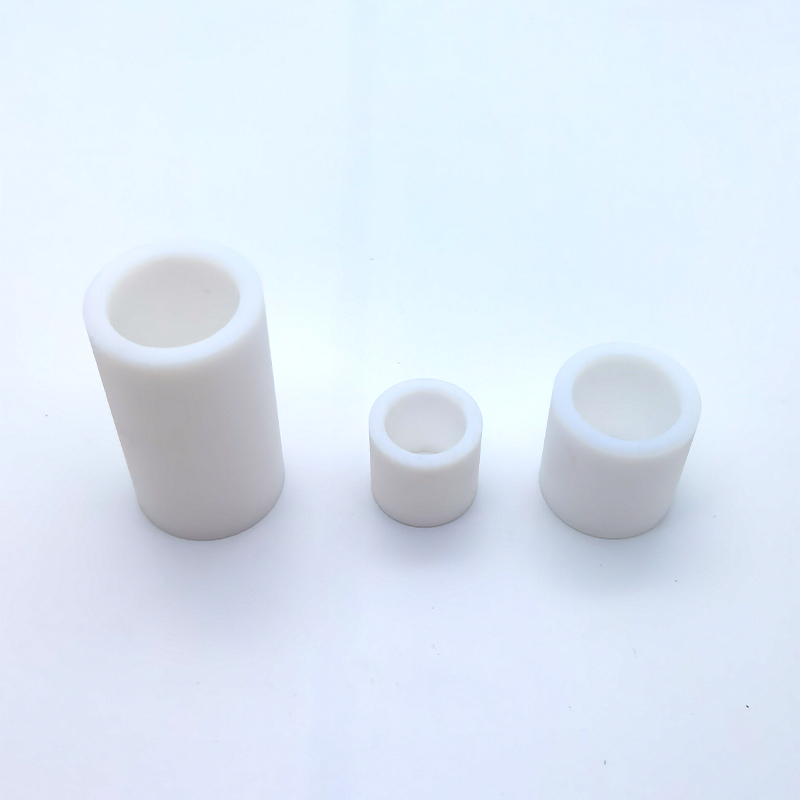

Detailed display

FAQ

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

If you have any questions about our goods or services, please feel free to contact us.

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code