Send My Request

Bost Plastic Spur Gears for Sale — Reliable, Low-Noise Performance

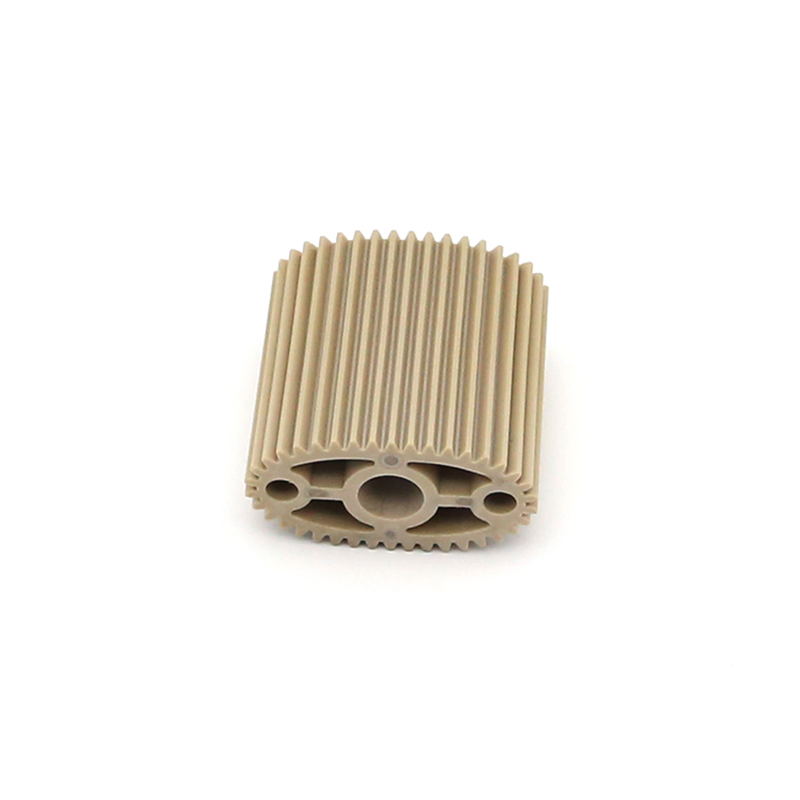

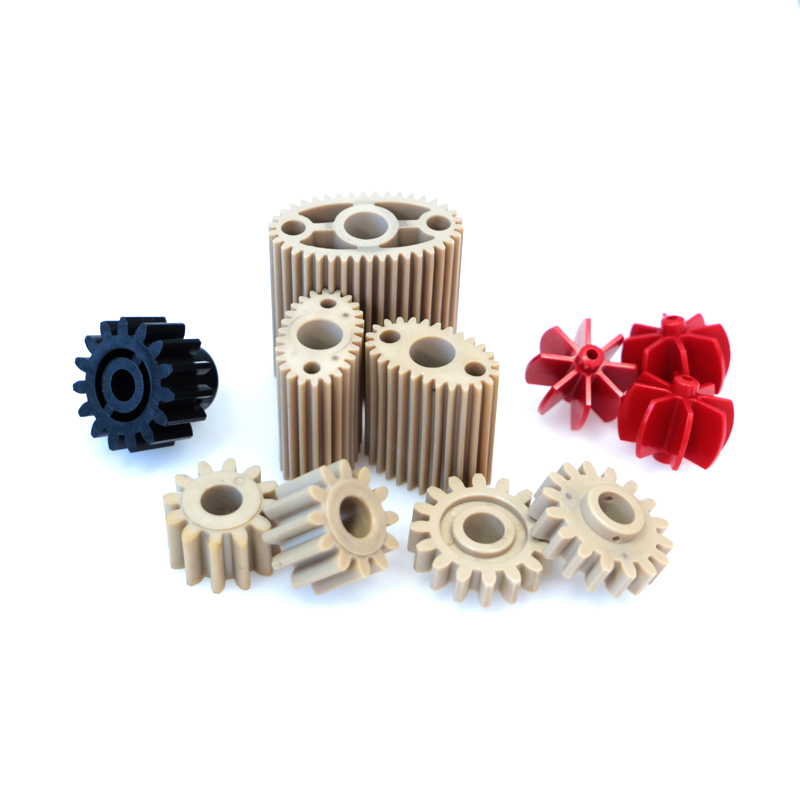

Bost Plastic Spur Gears for Sale

Bost plastic spur gears combine advanced engineering plastics with precise manufacturing to deliver quiet, long-lasting power transmission. Designed for a wide range of industries, our gears reduce weight and noise while offering excellent resistance to wear, corrosion and fatigue.

Why Choose Bost?

Bost is a professional, innovative high-tech manufacturer focused on green energy engineering plastics. We specialize in research, development and production of special engineering plastics with enhanced properties such as anti-scar, superior corrosion resistance, high abrasion resistance, and improved toughness. Our experienced R&D and production teams ensure each gear meets consistent quality and performance standards.

Key Features

- Lightweight and low-noise design — smoother operation and reduced vibration.

- High wear and abrasion resistance — longer service life in demanding applications.

- Corrosion resistant — ideal for moist or chemically active environments.

- Good fatigue strength — reliable under repeated loads.

- Custom sizes and materials — tailored to your equipment and torque needs.

Applications and Benefits

Our plastic spur gears are used in conveyors, packaging machines, printers, household appliances, robotics and light industrial equipment. Compared with metal gears, Bost plastic gears offer quieter operation, lower weight, no lubrication in many cases, and reduced manufacturing costs. This makes them an excellent choice for projects where noise reduction, cost efficiency and corrosion resistance matter.

Ordering & Support

Looking for plastic spur gears for sale? Bost provides quick quotes, custom machining and small-to-large production runs. We offer technical support to help you select the right material and dimensions for your application. Contact our sales team for samples, lead times and pricing.

Choose Bost for high-quality plastic spur gears that balance performance, durability and affordability. Get in touch today to discuss your requirements and request a competitive quote.

Product Image

FAQ

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code