Send My Request

Bost Shaft Component Protection

Reliable Shaft Component Protection by Bost

Bost offers shaft component protection solutions made from high-performance engineering plastics designed to extend service life, reduce maintenance, and ensure smooth operation. Our materials resist corrosion, abrasion, and fatigue while providing dimensional stability in demanding environments.

Key Benefits

- Excellent wear and abrasion resistance to reduce downtime and part replacement

- Superior corrosion resistance against chemicals, moisture, and harsh conditions

- High fatigue durability for components with repeated loads and motion

- Enhanced toughness and impact resistance to prevent cracking and chipping

- Custom sizes and shapes for easy retrofit or OEM integration

Practical Applications

Ideal for shafts in pumps, conveyors, gearboxes, mixers, and marine or chemical equipment. Bost components protect metal shafts from direct contact, reducing noise, vibration, and wear. They are suitable for both new designs and repair/upgrading of existing machinery.

Why Choose Bost?

Bost is a professional and innovative high-tech green energy engineering plastics manufacturer. We focus on R&D, production, and sales of specialized plastics with enhanced properties like anti-scar, super corrosion resistance, and high abrasion resistance. Our experienced team supports product mold design, precision machining, and tailored solutions so you get the right part for your application.

Easy Installation & Support

Components are delivered ready for fast installation. We offer technical guidance, material selection help, and custom machining options to ensure a perfect fit and reliable performance. Our goal is to make customers feel valued and confident in their equipment uptime.

Contact Bost to discuss shaft protection options and get a quote tailored to your equipment and environment.

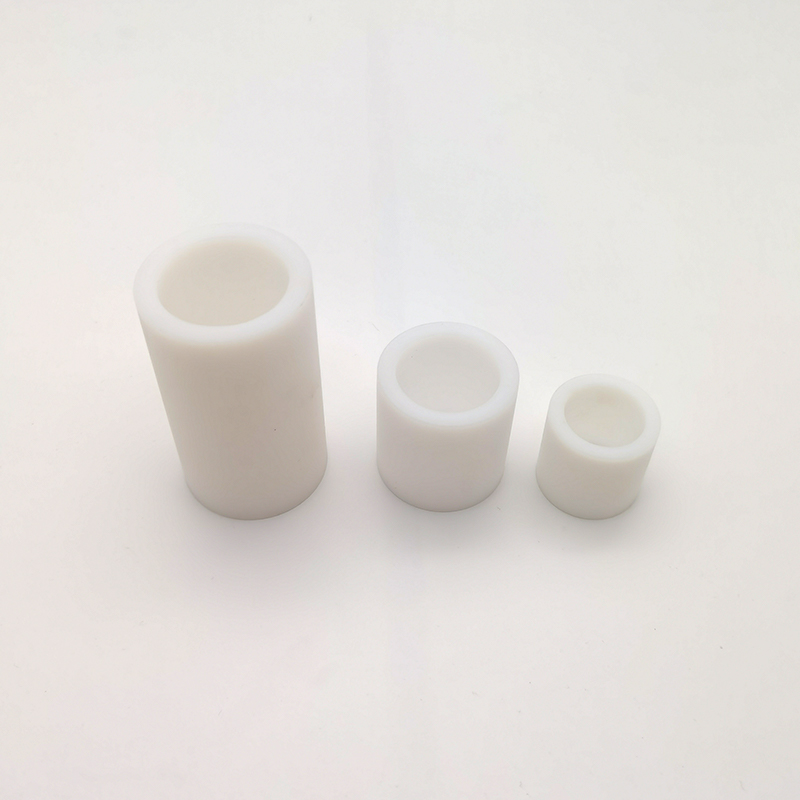

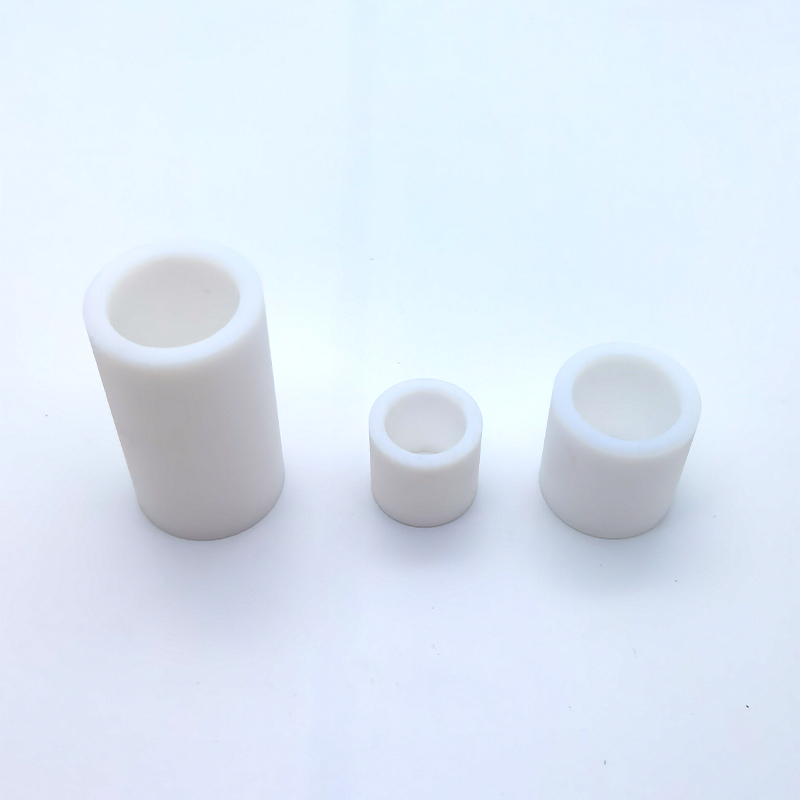

Product Images

FAQ

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code