Send My Request

Bost Self-Lubricating Guiding Engineering Plastics

Self-Lubricating Guiding Solutions by Bost

Product Overview

Bost Self-Lubricating Guiding materials are a specialized family of engineering plastics designed to minimize friction and maintenance while maximizing service life. Formulated for guiding, sliding and bearing applications, these materials combine intrinsic low-friction characteristics with enhanced toughness, abrasion resistance, and dimensional stability. Available as sheets, rods and custom-molded parts, they are ideal where continuous guiding performance and reduced lubrication are required.

Technical Advantages

Our Self-Lubricating Guiding products feature ultra-high anti-scar surfaces, superior corrosion resistance, and outstanding fatigue durability. High-temperature grades maintain transparency and mechanical strength, while flame-retardant and conductive-thermal formulations meet specialized safety and heat-dissipation needs. Bost’s modification technology improves impact toughness and wear resistance without compromising low friction, delivering consistent guiding performance under heavy loads and repetitive motion.

Typical Applications

Designed for high-demand environments, Self-Lubricating Guiding plastics perform excellently in linear guides, slideways, bushings, conveyor rails, food-processing guides, and steel-plastic hybrid components. They are widely used in automation equipment, packaging machines, molding tools, and marine or chemical environments where corrosion resistance and reduced maintenance are critical.

Why Choose Bost

Bost is a high-tech, green-energy engineering plastics manufacturer with strong R&D and production capabilities. Our team excels in material modification, mold design, and integrated steel-plastic solutions. We deliver custom formulations, precise machining, and reliable production capacity—ensuring parts meet exact tolerances and long-term field performance.

Service & Customization

We offer technical consultation, sampling, rapid prototyping and full-scale production. Bost supports customers through application testing, material selection, and post-sale service to optimize lifecycle costs and performance. For tailor-made Self-Lubricating Guiding solutions, contact our engineering team to evaluate your operating conditions and design requirements.

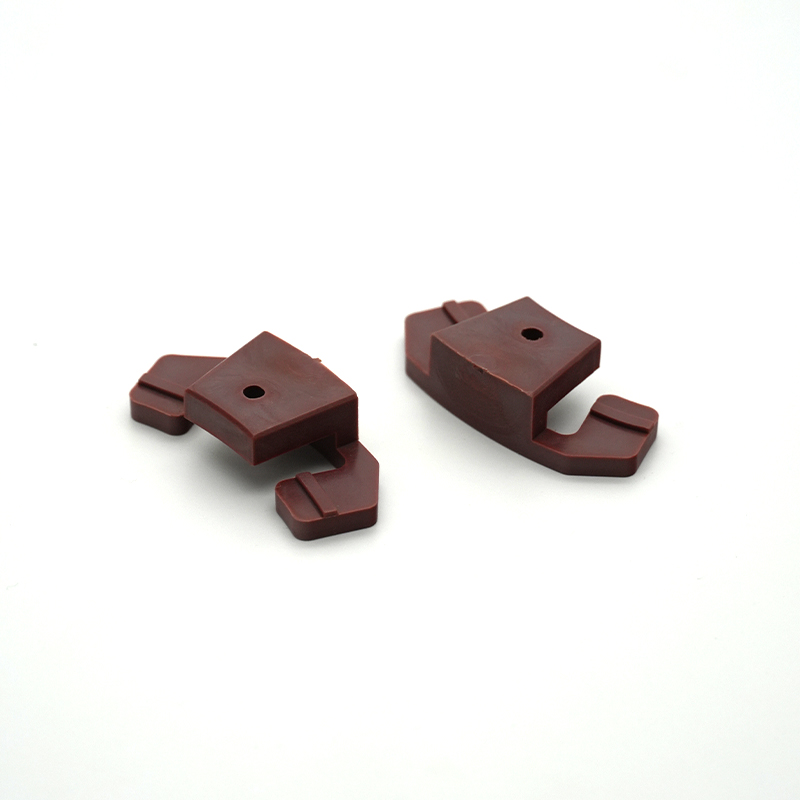

Self-Lubricating Guiding Display

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

The plastic plug manufactured by Insert molding with stainless steel plate

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

The Bost custom flow meter by injection molding with PES plastic

The plastic plug manufactured by Insert molding with stainless steel plate

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

The Bost custom flow meter by injection molding with PES plasticGet in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2026 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code