Send My Request

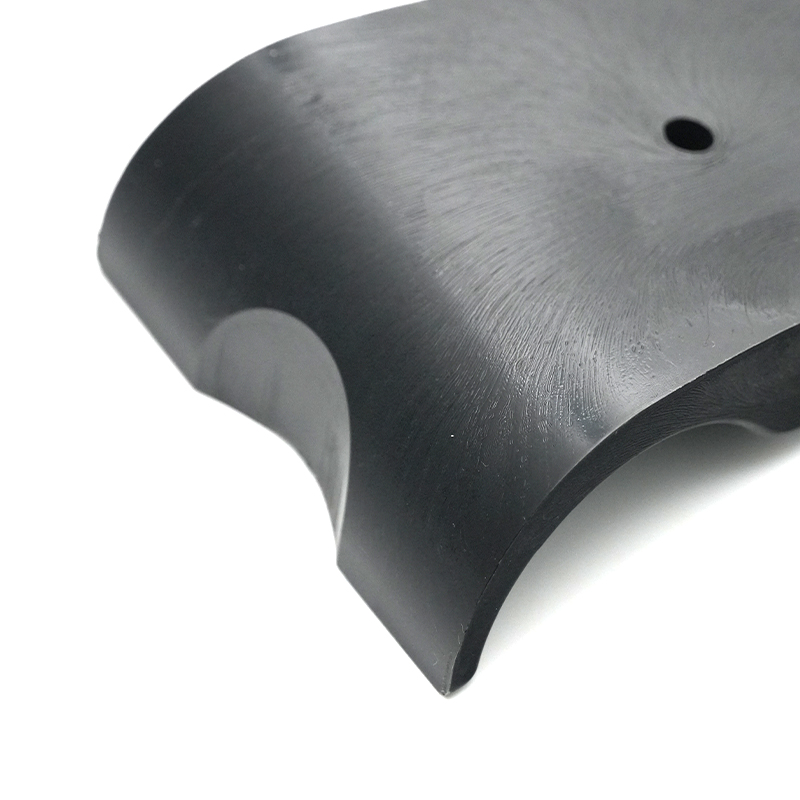

Black POM Injection-Molded Long-Lasting Spacing

Product Overview

What is Black POM Injection-Molded Long-Lasting Spacing?

Black POM Injection-Molded Long-Lasting Spacing from Bost is a precision-molded spacer made from high-quality polyoxymethylene (POM). Designed for demanding industrial applications, it provides stable dimensions, low friction and excellent wear resistance to keep assemblies running smoothly for longer.

Key Features and Benefits

Durability and Performance

- Long service life thanks to high wear and fatigue resistance

- Low friction surface reduces noise and wear on moving parts

- Stable under varying temperatures and loads, maintaining tight tolerances

Practical Advantages

- Corrosion-resistant and chemically stable for harsh environments

- Consistent injection-molded quality ensures interchangeability and fast installation

- Lightweight compared with metal spacers, reducing overall assembly weight

Common Applications

Where it works best

Ideal for machinery, automotive components, electrical assemblies, conveyor systems, and general industrial fixtures where reliable spacing, low wear and long-term dimensional stability are required.

Why Choose Bost

Trusted Manufacturer

Bost is a professional, innovative high-tech green energy engineering plastics manufacturer focusing on R&D, production and sales. Bost specializes in advanced modification and production of special engineering plastics, offering strict mold design, precise production and excellent quality control to ensure every spacer meets application needs.

Installation and Care

Simple Handling

Install like standard spacers—inspect for correct fit and alignment. Minimal maintenance required: periodic inspection and cleaning extend life. Avoid prolonged contact with incompatible solvents.

Value Proposition

Cost-Effective Reliability

Choosing Bost Black POM Injection-Molded Long-Lasting Spacing reduces downtime and replacement frequency, delivering lower total cost of ownership and dependable performance in industrial environments. Contact Bost for custom sizes and volume orders.

Picture Show

FAQ

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code