Send My Request

Bost Custom CNC Machined Parts

Overview

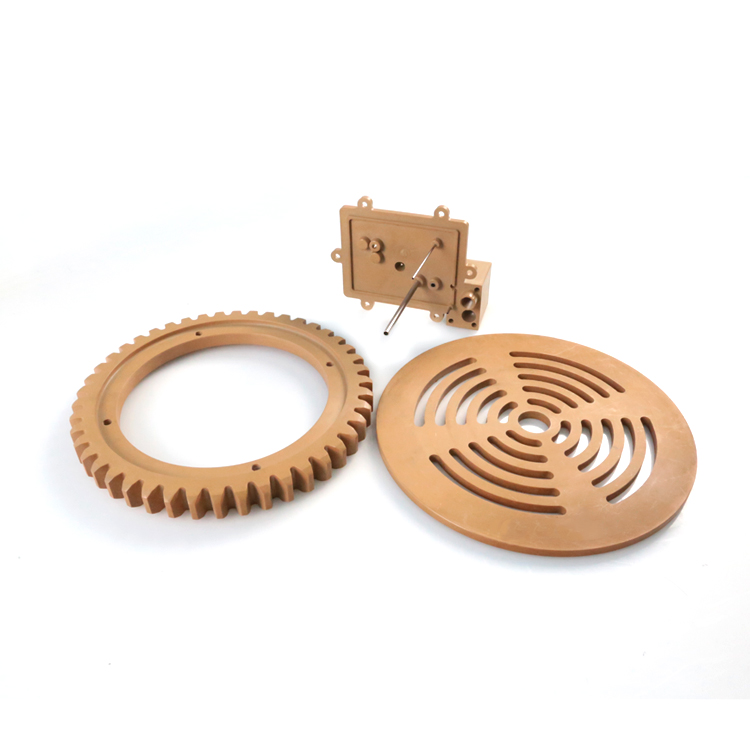

Bost custom CNC machined parts combine advanced engineering plastics with precise machining to deliver reliable components for demanding applications. As a professional, innovative and green-energy focused manufacturer, Bost specializes in producing materials and finished parts that offer superior wear resistance, corrosion resistance, high temperature performance and tailored mechanical properties.

Key Benefits

Durability and Performance

Our parts use specially modified engineering plastics that resist abrasion, fatigue and chemical attack. That means longer life, fewer failures and reduced maintenance for your products.

Precision and Fit

CNC machining ensures accurate dimensions and consistent surface finishes. We deliver tight, repeatable tolerances so components fit and function as intended in assemblies and machinery.

Materials and Properties

Bost works with a wide range of sheets, rods and molded plastics, including ultra-wear-resistant, anti-scratch, flame-retardant, conductive and high-temperature transparent grades. We also integrate enhanced toughness, thermal conductivity and steel-plastic combinations for hybrid solutions.

Manufacturing Capabilities

From Prototype to Production

We support rapid prototyping and scalable production runs. Our services include design for manufacturability, mold design, precision CNC machining, secondary processing and careful packaging for delivery.

Quality Assurance

Every part undergoes strict inspection and testing to meet customer requirements. Our experienced production team and R&D engineers ensure material performance and dimensional accuracy before shipment.

Applications

Typical uses include components for automotive, energy, electronics, industrial machinery, and other sectors that require durable, lightweight and corrosion-resistant parts.

Why Choose Bost

Bost offers deep expertise in modifying engineering plastics and strong production capacity. We combine R&D, mold-making and precision machining to deliver parts you can trust. Contact us for a quote, material guidance or design support to bring your project to life.

Product Images

FAQ

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

If you have any questions about our goods or services, please feel free to contact us.

Machined parts-CNC complex and precision plastic parts

Machined parts-CNC complex and precision plastic parts

PP plastic head with UL properties by Injection molding

PP plastic head with UL properties by Injection molding

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code