Send My Request

Bost Custom Plastics Injection Molding — Durable, High-Precision Solutions

Custom Plastics Injection Molding by Bost

Bost is a professional, innovative high-tech manufacturer focused on green energy engineering plastics. Our custom plastics injection molding service combines advanced material science with precise mold design to deliver durable, high-performance plastic parts for industrial, automotive, medical, and consumer applications.

Why choose Bost?

- Material expertise: We produce engineered plastics with superior abrasion resistance, corrosion resistance, fatigue durability, flame retardancy, and high-temperature transparency.

- Precision molding: In-house mold design and manufacturing ensure tight tolerances and consistent part quality.

- Customer-first service: Fast prototyping, responsive communication, and tailored production runs to match your schedule and budget.

Practical Benefits for Your Products

Our injection molded parts translate technical advantages into real value: longer-lasting components, fewer failures in harsh environments, lighter assemblies, and improved appearance for visible parts. Whether you need small precision components or large, structurally demanding parts, Bost optimizes material selection and mold design to reduce cost and increase lifetime.

Applications and Use Cases

Bost parts are widely used in industrial machinery, electrical housings, automotive components, consumer products, and specialized equipment requiring combined properties like conductivity, toughness, and temperature resistance. We also support hybrid solutions that combine steel, rubber, and plastic where needed.

Quality, Testing, and Support

Every project benefits from our experienced R&D and production teams. We perform material verification, dimensional inspection, and performance testing to ensure parts meet specifications. Our goal is to deliver reliable parts on time and provide clear technical support throughout the product lifecycle.

Contact Bost to discuss custom plastics injection molding for your next project. We focus on practical, cost-effective solutions that protect performance and enhance product value.

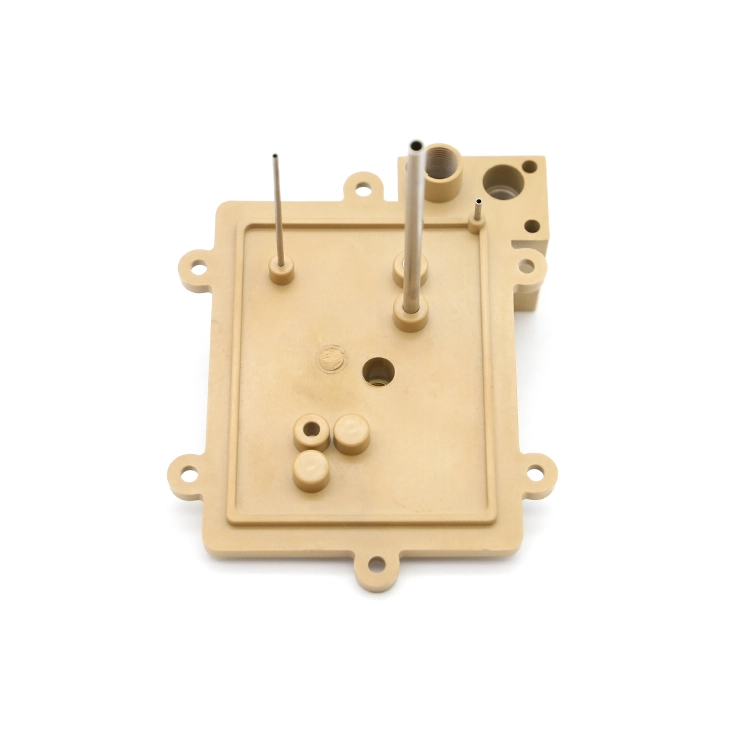

Product Images

Q&A

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

If you have another questions, please feel free to contact us.

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code