Send My Request

Light weighting - High performance plastic parts replacement Metal parts

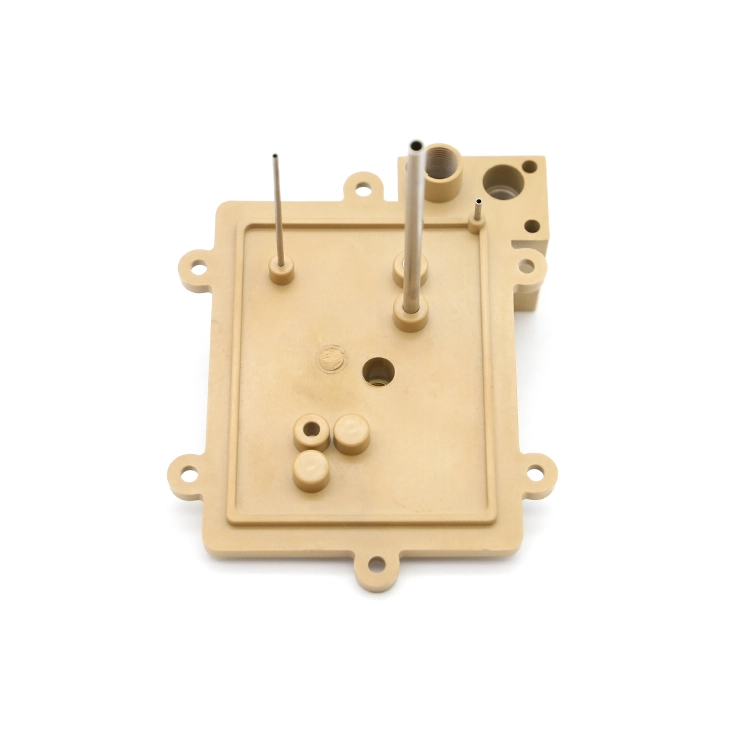

Bost delivers light-weighting: replace metal with High performance plastic parts using Injection molding and engineered plastics for superior strength, durability and cost savings. Discover how Bost improves performance and reduces weight.

- Light weighting - High performance plastic parts replacement Metal parts

- I. Defining

- II. Real-World Application Cases

- 1. Automotive: Battery Enclosures (Aluminum → Carbon-Fiber Reinforced Plastic)

- 2. Material Handling: Forklift Sliders (Brass → PA66 GF30)

- 3. Chemical Industry: Pipes & Valves (Stainless Steel → PP)

- III. Core Advantages of Plastics Over Metals

- 1. Cost Efficiency

- 2. Design Freedom & Manufacturing Speed

- 3. Lightweighting & Sustainability

- 4. Performance Superiority

- IV. Key Application Industries

- V. Future Trends

- Conclusion

Light weighting - High performance plastic parts replacement Metal parts

In the landscape of industrial innovation, the replacement of metal with high performance plastics—known as "plastic for metal"—has emerged as a pivotal trend. This shift is not merely a cost-cutting measure but a strategic transformation that enhances product performance, simplifies manufacturing, and reduces environmental impact. By leveraging the unique properties of engineered plastics, industries ranging from automotive to aerospace are redefining what’s possible in design and functionality. This article explores real-world applications, tangible benefits, and the sectors driving this material revolution.

I. Defining

At its core, "plastic for metal" refers to the substitution of traditional metal components with advanced engineered plastics without sacrificing quality or performance. The goal is to achieve light weighting, cost reduction, design flexibility, and improved durability. Unlike commodity plastics, engineered variants—such as glass-fiber reinforced polypropylene (PP), polyamide (PA66), and polycarbonate (PC) blends—deliver mechanical strength, chemical resistance, and thermal stability comparable to metals like steel, aluminum, and brass .

II. Real-World Application Cases

1. Automotive: Battery Enclosures (Aluminum → Carbon-Fiber Reinforced Plastic)

Background: New Energy Vehicles demand lightweight, fire-resistant battery protection. Traditional aluminum battery enclosures add weight and require complex assembly.

Solution: replaced aluminum with carbon-fiber reinforced plastic for a NEV battery power compartment.

Replacement Effects:

• 37% weight reduction, improving vehicle range by 8–10%.

• 11% more under-chassis space via optimized design.

• Elimination of welding/riveting: assembly time cut by 60%.

• Cost reduction of 28% (from material and labor savings).

2. Material Handling: Forklift Sliders (Brass → PA66 GF30)

Background: Brass sliders in forklift attachments require constant lubrication and corrode in harsh environments.

Solution: Technoform and KAUP replaced brass with glass-fiber reinforced PA66 (PA66 GF30) .

Replacement Effects:

• 10,000-cycle endurance test passed (with/without lubricant).

• 40% less energy required for part movement (reduces forklift fuel consumption).

• Suitable for food-grade applications (lubricant-free, no contamination risk).

• 75% lower CO₂ footprint (GWP: 4.3 vs. 20.9 kg CO₂eq/m for brass).

3. Chemical Industry: Pipes & Valves (Stainless Steel → PP)

Background: Metal pipes corrode in acidic/alkaline environments, leading to leaks and frequent replacements.

Solution: A chemical plant replaced 316 stainless steel with PP rods .

Replacement Effects:

• 2-year resistance to 5% hydrochloric acid (no corrosion vs. steel’s 3-day failure).

• 8-year maintenance-free lifespan (vs. steel’s annual upkeep).

• 60% lower total cost of ownership (TCO).

III. Core Advantages of Plastics Over Metals

1. Cost Efficiency

• Direct Savings: Plastics reduce costs by 25–50% . For example, a 38-part metal automotive assembly became a 1-part plastic component .

• Indirect Savings: Fewer fasteners, no secondary finishing (painting/plating), and longer mold life (500k+ cycles for plastic vs. 100k for metal die-casting) .

2. Design Freedom & Manufacturing Speed

• Complexity: Injection molding creates integrated features (threads, clips, ribs) that metal machining cannot match. A plastic part can replace 5+ metal components .

• Speed: Metal parts take 5–7 days (cutting → heat treatment → finishing); plastic parts take 1–2 days (cutting → molding) .

3. Lightweighting & Sustainability

• Weight: PP’s density (0.9g/cm³) is 1/8 of steel and 1/3 of aluminum . Aerospace weight reduction of 1kg saves $10k/year in fuel .

• Eco-Friendliness: Plastic scrap is 100% recyclable (vs. <60% for metal) , and production uses 1/5 the energy of metal processing .

4. Performance Superiority

• Corrosion Resistance: PP outlasts stainless steel in chemicals and saltwater .

• Insulation: Plastics are natural insulators)(15kV/mm for PP vs. metal’s need for coatings) .

• Wear Resistance: Self-lubricating plastics (e.g., oil-filled nylon) eliminate grease needs .

IV. Key Application Industries

|

Industry |

Typical Replacements |

Driver Benefit |

|

Automotive |

Engine covers, door handles, battery enclosures |

Lightweighting, cost cut |

|

Aerospace |

Interior panels, cable trays |

Fuel efficiency |

|

Renewable Energy |

Solar frames, wind turbine parts |

Durability, installation ease |

|

Medical |

Surgical instruments, device housings |

Sterilizability, corrosion resistance |

|

Chemical |

Pipes, valves, tanks |

Chemical resistance |

|

Logistics |

Forklift parts, conveyor components |

Low maintenance |

V. Future Trends

The "plastic for metal" revolution is accelerating with advancements in composite materials (e.g., carbon-fiber reinforced plastics) and digital design tools. Future innovations will focus on:

• Metal-plastic hybrids (combining strength and flexibility).

• Recycled engineered plastics (reducing GWP by 5x) .

• AI-driven material selection (matching plastics to exact performance needs).

Conclusion

"Plastic for metal" is more than a material swap—it’s a paradigm shift that empowers industries to build better, lighter, and more sustainable products. From automotive battery enclosures to solar frames, real-world cases prove that plastics not only match metal performance but often exceed it. As engineered plastics continue to evolve, their role in manufacturing will only grow, driving efficiency and innovation for decades to come.

Recommended for you

FAQ

FAQs

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

You may also like

Insert molding solutions for plastic mould manufacturer

Injection molding parts-Precision plastic parts custom

Customized Plastic Injection molding -faster delivery and economical

Leave a Message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2026 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code