Send My Request

Bost Custom Insert Molding — Reliable Engineering Plastics Solution

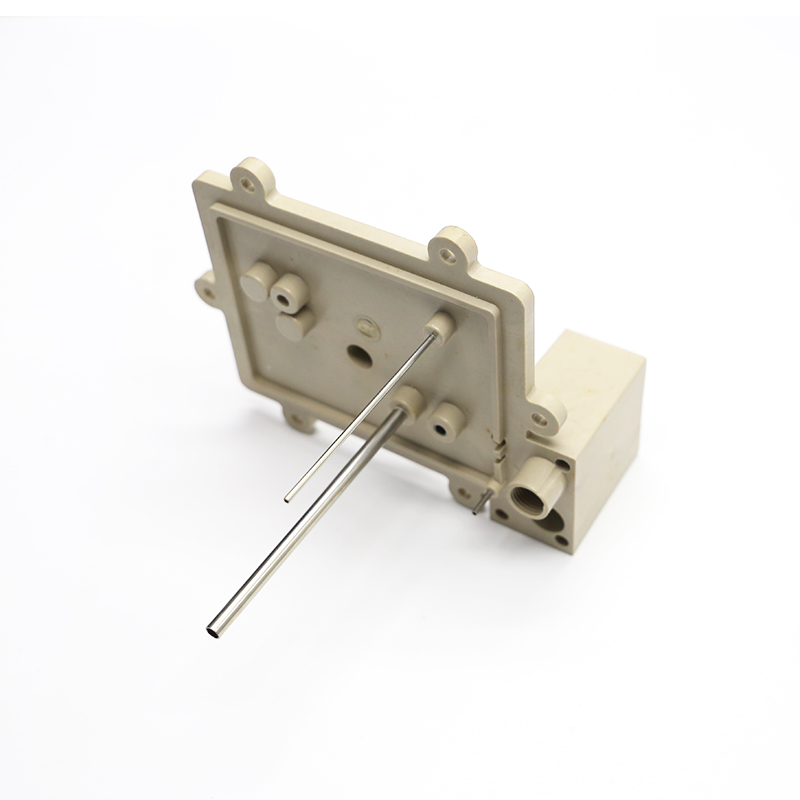

What is Bost Custom Insert Molding?

Custom insert molding is a process where metal or other components are placed into a mold and plastic is molded around them to form a single, unified part. Bost uses advanced engineering plastics and experienced mold design to deliver strong, accurate, and long-lasting components for demanding industries.

Why Choose Bost?

Bost is a professional, innovative, high-tech green energy engineering plastics manufacturer. We combine deep material know-how with precision mold-making and production capability. Our team focuses on special engineering plastics with properties such as high abrasion resistance, exceptional corrosion protection, fatigue durability, high-temperature transparency, flame retardancy, and thermal conductivity.

Key Benefits

- Strong bond between plastic and insert—reduces part failure and loosening.

- Improved durability—high resistance to wear, corrosion and fatigue.

- Precision fit—tight tolerances reduce assembly time and cost.

- Material customization—options for flame retardant, conductive, or transparent grades.

- Steel-plastic and plastic-rubber combinations—designed for high-performance products.

Applications

Our custom insert molded parts are used in automotive, electrical, renewable energy, industrial machinery, consumer electronics, and medical devices. Wherever a secure, integrated component is needed, insert molding reduces fasteners and improves product reliability.

Quality & Innovation

Bost maintains strict process control from R&D and mold design through to production and final inspection. Our modification team enhances toughness and other special properties to meet customer specifications. We emphasize eco-friendly practices and scalable production to support small runs and large volumes alike.

Get Started

If you need a reliable custom insert molding partner, Bost offers expert design support, prototype testing, and full production services. Contact us to discuss materials, tolerances, and cost-effective manufacturing solutions tailored to your product needs.

Product Images

Question you may concern

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

If you have any questions or concern, please contact us.

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code