Send My Request

Bost Custom Plastic Injection Molding

About Bost

Bost is a professional, innovative and high-tech manufacturer of green energy engineering plastics. We focus on R&D, production and sales of special engineering plastics, offering reliable products and attentive service to ensure customer satisfaction.

Custom Plastic Injection Molding Services

We provide custom plastic injection molding that turns your design into durable parts. Our services include material selection, mold design and manufacturing, precision molding, and post-processing. Bost specializes in modified engineering plastics with special properties such as ultra anti-scar, super corrosion resistance, fatigue durability, ultra abrasion resistance, high temperature transparency, flame retardancy and enhanced toughness.

What we deliver

Every project receives a tailored approach. We match material and process to the part function, whether you need strength, wear resistance, thermal conductivity, electrical conductivity, or a combination of steel-plastic and rubber-plastic assemblies. Our team handles prototype to production, ensuring consistent quality and on-time delivery.

Why choose Bost?

- Technical expertise: experienced R&D team for plastic modification and mold engineering.

- Full production capability: in-house mold making, mechanical processing and assembly.

- Material variety: sheets, rods and molded parts in special engineering plastics.

- Customer focus: clear communication, quality checks and responsive after-sales support.

Practical Value for Your Project

Custom injection molding with Bost reduces development time and production risk. By choosing the right modified engineering plastic, you get parts with longer life, better performance, and lower maintenance. Our solutions help you meet stricter product requirements without sacrificing manufacturability or cost control.

Applications

Our molded parts serve industries such as automotive, electronics, industrial machinery, energy, and consumer products. Typical uses include wear components, housings, connectors, seals and structural parts that require special resistance or toughness.

Get Started

Contact Bost to discuss your requirements. We offer technical consultation, rapid prototyping, and scalable production to bring your idea from concept to reliable product. Trust Bost for custom plastic injection molding that balances performance, quality and cost.

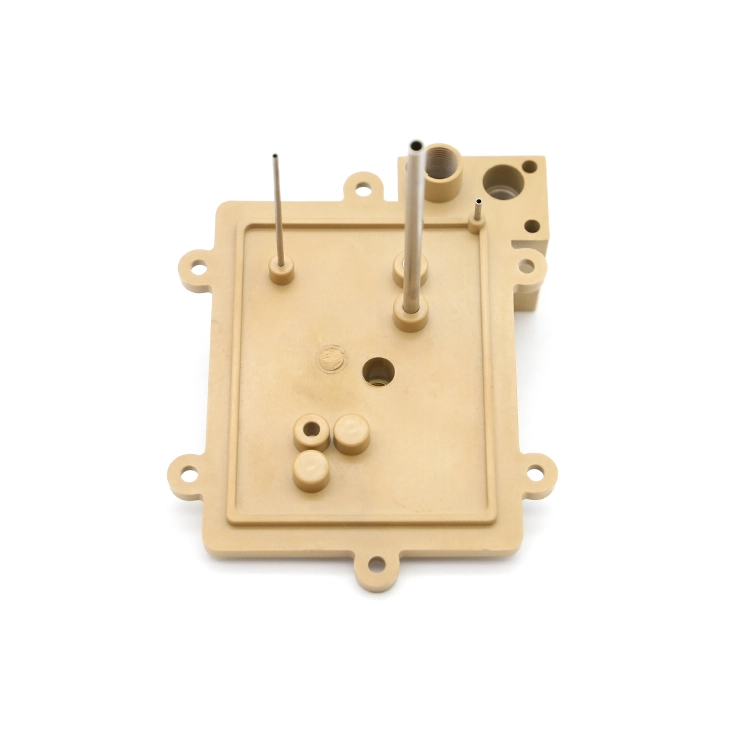

Picture Show

Question you may concern

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

BOST Injection molding -Customized and OEM Supplier

BOST Injection molding -Customized and OEM Supplier

Customized Plastic Injection molding -faster delivery and economical

Customized Plastic Injection molding -faster delivery and economical© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code