Send My Request

Customized Plastic Injection molding -faster delivery and economical

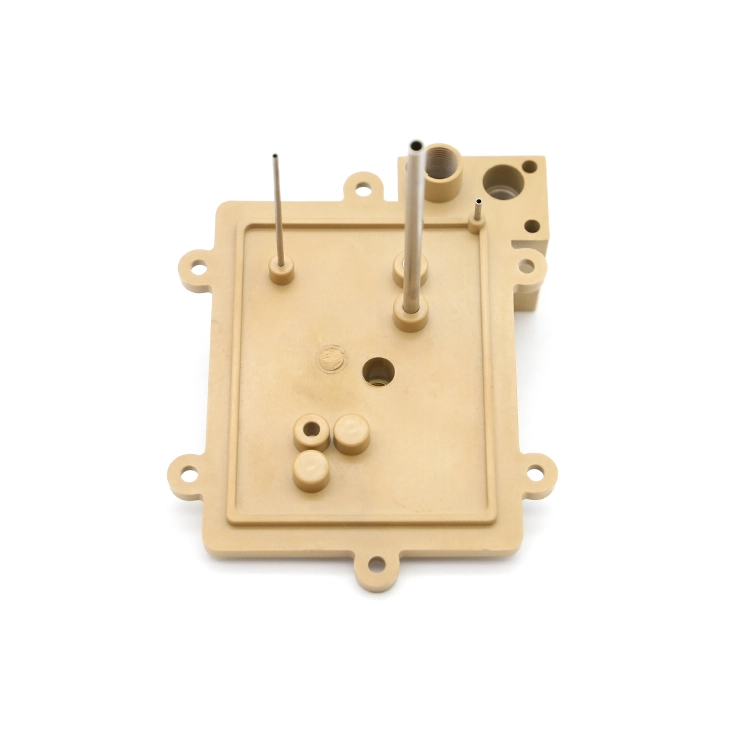

Plastic injection molding is a manufacturing process in which molten plastic is injected under high pressure into a mold cavity, then cooled and solidified to form a final product. Once the plastic has hardened, the mold opens, and the part is ejected.

Performance advantages and application fields of Plastic injection molding

Advantages of Plastic injection molding

This process offers several advantages. Firstly, it enables high-volume production with consistent quality, reducing per-unit costs significantly.

Secondly, it allows for the creation of complex geometries, including intricate internal structures, thin walls, and undercuts, with high precision.

Thirdly, the surface finish of injection-molded parts can be excellent, often requiring little to no post-processing.

Additionally, the process is highly automated, minimizing labor costs and human error.

Features of Plastic injection molding

A wide range of materials can be used in plastic injection molding.

Thermoplastics are the most common, including ABS (Acrylonitrile Butadiene Styrene), known for its impact resistance and ease of use; polyethylene, used in various packaging applications due to its flexibility and chemical resistance; and polypropylene, valued for its high melting point and fatigue resistance. Engineering plastics like nylon (polyamide), with its high strength and abrasion resistance, and polycarbonate, which offers excellent transparency and impact strength, are also popular.

Thermosetting plastics can be used in injection molding for applications requiring high heat resistance and chemical stability, although they are less common than thermoplastics.

Applications of Plastic injection molding

Products with complex shapes and those required in large quantities are ideal for plastic injection molding.

For example, automotive components such as dashboards, door handles, and engine parts; consumer electronics like smartphone cases and keyboard keys; and household items like toys, utensils, and furniture components. Parts that demand high dimensional accuracy and repeatability also benefit from this process.

You may also like

Get a Free Quote

Contact our team now for competitive pricing, detailed product specifications, and customized solutions—100% free.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code