Send My Request

Bost Customized Injection Moulding Services

About Bost Customized Injection Moulding

Bost is a professional, innovative and green-energy focused manufacturer of engineering plastics. Our customized injection moulding service turns advanced plastic materials into precise, high-performance parts for a wide range of industries. We combine experienced R&D, careful mold design, and skilled production to ensure consistent quality and on-time delivery.

What We Offer

Tailored Solutions

We provide tailored injection moulding solutions to meet your product requirements. Whether you need parts with ultra-high abrasion resistance, superior corrosion resistance, high fatigue life, or transparent high-temperature properties, Bost can adapt materials and processes to match your needs.

Material and Process Expertise

Our team specializes in modifying engineering plastics to add toughness, flame retardancy, conductivity and thermal properties. We work with rods, sheets and custom molds, and we are skilled at combining steel, plastic and rubber for hybrid products. This expertise ensures parts perform reliably in demanding conditions.

Why Choose Bost

Quality and Reliability

Bost emphasizes strict quality control across mold design, tooling, and production. Our experienced engineers and production teams deliver repeatable results, minimizing defects and keeping production stable. Customers trust us for parts that meet performance and safety requirements.

Sustainability and Support

As a green-energy oriented company, Bost focuses on efficient processes and responsible material choices. We provide clear communication throughout the project, from prototype to mass production, and offer technical support to optimize part design and manufacturing costs.

Applications

Our customized injection moulding parts are used in automotive, electronics, industrial equipment, consumer goods and more. If your project requires durable, corrosion-resistant or high-temperature plastic components, Bost delivers practical, tested solutions.

Contact Bost today to discuss your custom injection moulding needs and get a reliable quote backed by technical expertise and proven production capability.

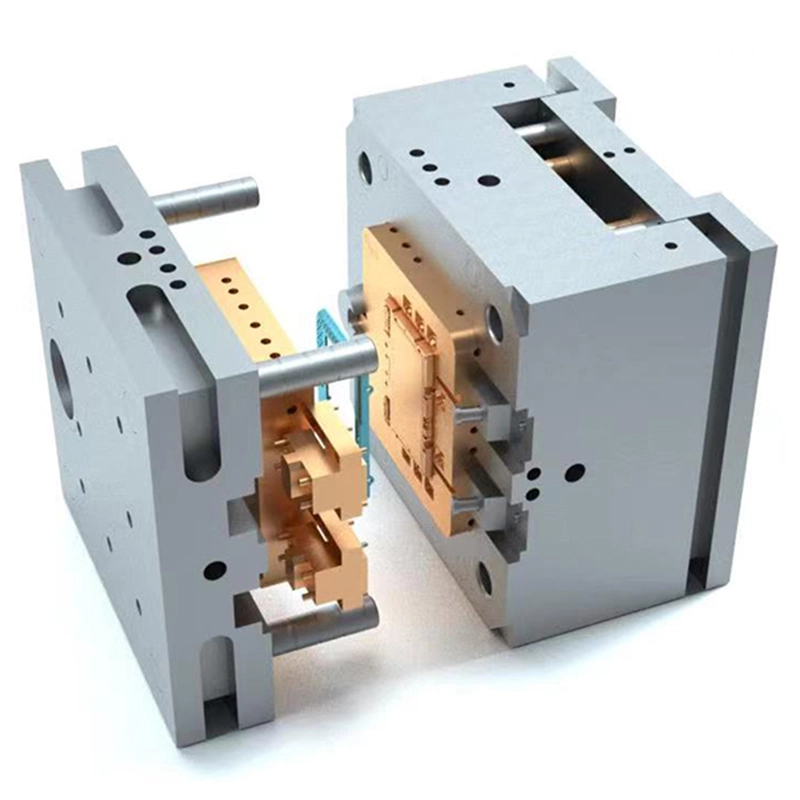

Product Images

Q&A

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

Custom Larger and precision injection mould with high performance plastic

Custom Larger and precision injection mould with high performance plastic© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code