Send My Request

Bost High Wear Resistance & Low Friction Engineering Plastics

Bost High Wear Resistance & Low Friction Engineering Plastics

Bost delivers engineered plastics designed for demanding industrial use where low friction and long wear life matter. Our materials reduce downtime, lower replacement costs, and improve equipment efficiency. Made by a green-energy high-tech manufacturer, these plastics are ideal for conveyor systems, bearings, wear liners, seals, and custom machine parts.

Key Features

- High wear resistance that extends service life

- Low friction to reduce energy loss and heat

- Good chemical and corrosion resistance

- Excellent machinability for fast prototyping and production

- Available in sheets, rods and custom molded parts

Practical Benefits

Choosing Bost materials means less frequent part replacement and lower maintenance costs. Low friction lowers power consumption and reduces noise, while high wear resistance preserves dimensions and performance over time. Simple machining and stable properties make our plastics easy to integrate into existing designs.

Common Applications

- Sliding guides, wear pads and liners

- Bushings, bearings and sleeves

- Conveyor components and chute liners

- Gears, sprockets and machine parts exposed to abrasion

Why Bost

Bost combines deep R&D in modified engineering plastics with strong production capability. We focus on performance improvements like anti-scar, fatigue durability, flame retardancy, and conductive thermal properties. Our team supports mold design, mechanical processing, and durable steel-plastic composite solutions for high-tech products.

Get Started

If you need a longer-lasting, low-friction solution, contact Bost for samples, material datasheets, or custom development. We prioritize quality and customer satisfaction to deliver practical materials that save time and cost.

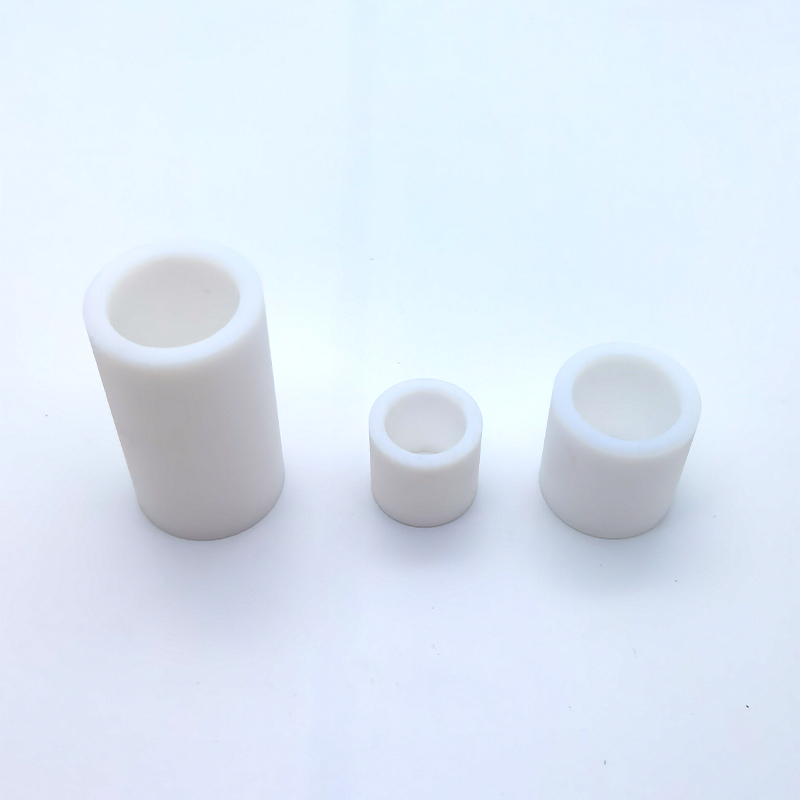

Product Image

FAQ

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code