Send My Request

Bost Injection Molding Plastic — Durable Engineering Plastics for High-Performance Parts

About Bost and Our Injection Molding Plastics

Bost is a professional and innovative high-tech green energy engineering plastics manufacturer. We specialize in R&D, production and sales of engineering plastics designed for injection molding. Since our founding, we have focused on producing reliable materials that meet strict performance and quality needs.

Key Features of Our Injection Molding Plastic

- Ultra-high anti-scar and abrasion resistance for long-lasting parts.

- Excellent corrosion resistance and fatigue durability for harsh environments.

- High-temperature transparent grades for optical and high-heat applications.

- Enhanced toughening, flame retardancy and balanced thermal conductivity.

- Available as sheets, rods and molded components with precise tolerances.

Manufacturing Strengths

We combine advanced plastic modification technology with in-house mold design and manufacturing. Our team integrates steel-plastic and plastic-rubber solutions to produce complex parts reliably and at scale. Injection molding offers repeatable precision, fast cycle times and minimal waste — ideal for high-volume production.

Practical Benefits and Value to Customers

Bost injection molding plastic is designed to solve real problems. Parts made from our materials last longer, reduce maintenance costs and perform consistently under stress. Our products are easy to process, compatible with automated mold systems and supported by technical guidance from our experienced R&D team.

Who Should Choose Bost

If you need durable components for industrial, automotive, electrical or consumer applications, Bost provides tailored grades and professional support. We prioritize customer satisfaction, timely delivery and product performance so your projects run smoothly.

Contact and Next Steps

Choose Bost for reliable injection molding plastics that deliver measurable value. Contact our technical team for material selection, mold recommendations and samples tailored to your application.

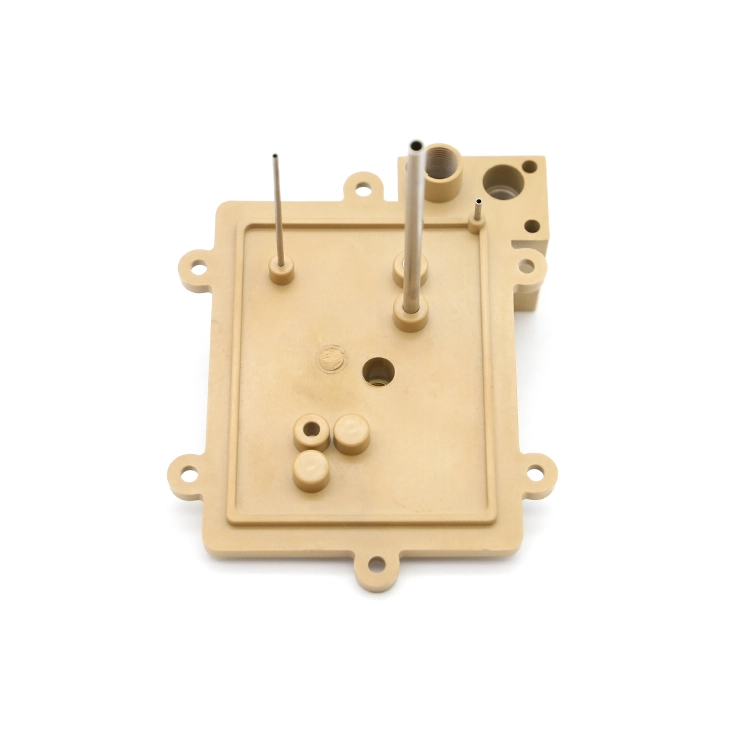

Product Images

Frequently Asked Questions

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code