Send My Request

Bost Plastic Injection Molding Service — High-Performance Engineering Plastics

Bost Plastic Injection Molding Service — Precision, Durability, Speed

Bost is a professional, innovative high-tech green energy engineering plastics manufacturer. We specialize in plastic injection molding services that turn advanced engineering plastics into reliable, high-performance parts. From prototype to mass production, Bost delivers quality, consistency, and fast turnaround.

What We Offer

- Custom injection molding and mold design

- Material modification: enhanced toughness, flame retardancy, conductivity

- Special properties: anti-scratch, corrosion resistance, fatigue durability, ultra abrasion resistance, high-temperature transparency

- Steel-plastic and plastic-rubber composite molding

- Rapid tooling, prototype validation, and high-volume production

Why Choose Bost?

Our experienced R&D and production teams excel in modifying engineering plastics to meet specific demands. We combine advanced material science with precise mold-making and mechanical processing. This means parts that last longer, perform better, and are produced with stable quality. Key advantages include:

- Superior material performance for harsh environments

- High dimensional accuracy and repeatability

- Cost-effective production from small batches to large runs

- Strong quality control and testing at every stage

Applications

Bost injection molded parts are used across industries: automotive components, electronic housings, green energy systems, medical devices, industrial machinery, and consumer products. Our ability to integrate steel-plastic designs and tailor material properties makes Bost ideal for demanding applications.

Fast, Clear Process

We keep the process simple: consult → design → prototype → validate → produce. Transparent communication and on-time delivery are core to our service.

Get Started

Whether you need a robust prototype or scalable production, Bost offers reliable injection molding solutions that boost product performance and reduce risk. Contact us today to discuss your project and get a fast quote.

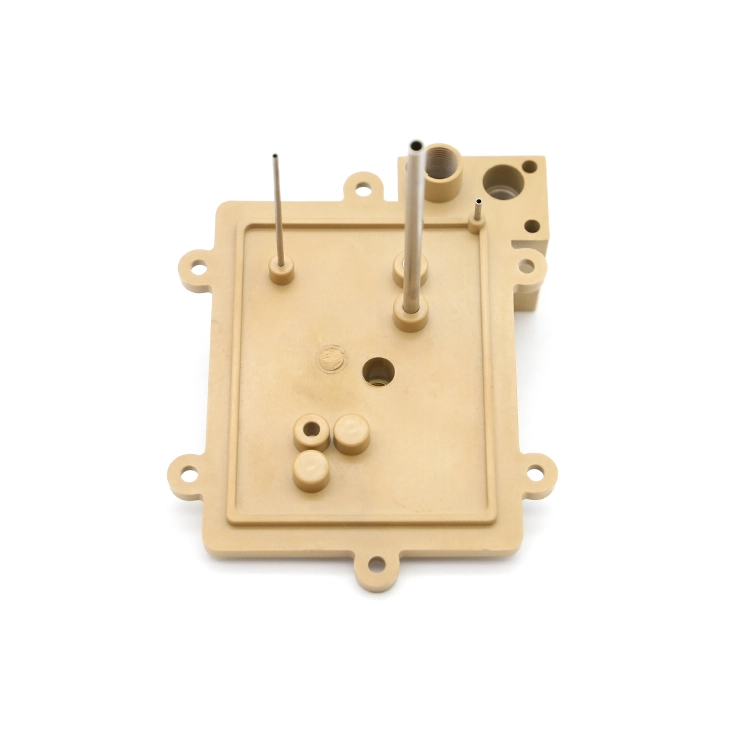

Product Image

Question you may concern

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code