Send My Request

Bost Insert Injection Molding – Reliable Overmolding Solutions

What is Insert Injection Molding?

Insert injection molding is a manufacturing method where metal or pre-formed components are placed into a mold and plastic is injected around them to form a single, integrated part. This process creates strong, sealed assemblies with excellent mechanical and thermal performance. Bost applies its deep expertise in engineering plastics to deliver parts that meet demanding industrial standards.

How Bost Does It Differently

At Bost, we combine advanced material science with precise mold design and experienced production teams. Our focus on modified engineering plastics—such as high-heat, abrasion-resistant, and corrosion-resistant grades—ensures that insert molded parts stand up to tough environments. We also provide enhanced properties like improved toughness, flame retardancy, and thermal conductivity when required.

Key Benefits of Bost Insert Injection Molding

- Strength and Durability: Overmolded parts produced by Bost resist fatigue, wear, and impact.

- Corrosion and Temperature Resistance: Suitable for harsh environments and high-temperature applications.

- Precision and Consistency: Tight tolerances and repeatable results thanks to advanced molds and quality control.

- Improved Functionality: Integrated seals, electrical insulation, or conductive paths can be built into a single part.

- Cost-Effective Production: Combines multiple components into one assembly, lowering assembly time and cost.

Typical Applications

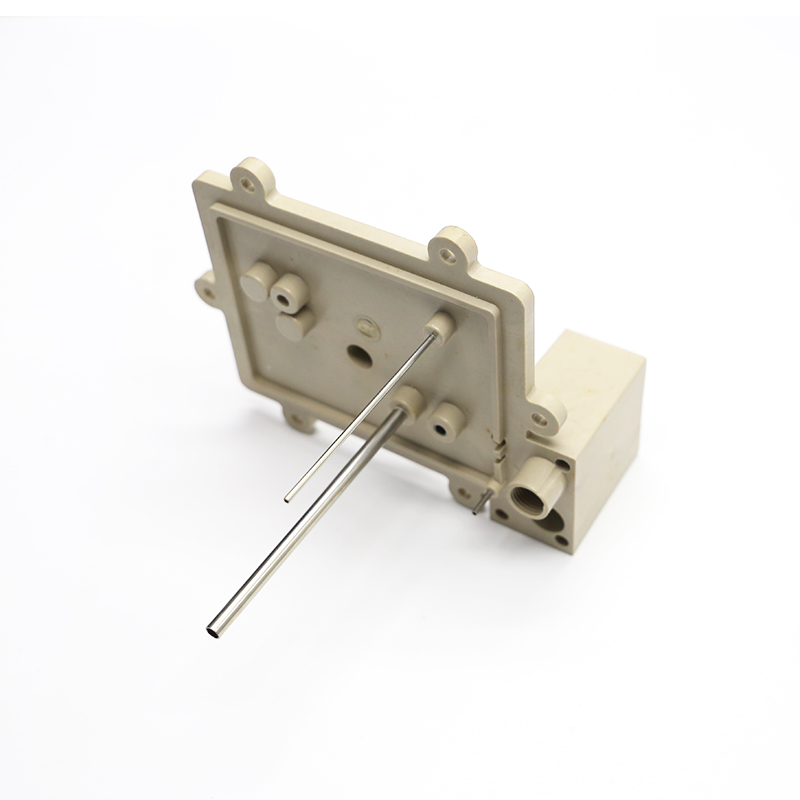

Bost insert injection molding serves industries such as automotive, electronics, renewable energy, medical devices, and industrial equipment. Common parts include threaded inserts, metal-to-plastic housings, sensors, connectors, and structural components requiring combined material properties.

Quality, Customization, and Support

Bost is a professional, innovative high-tech green energy engineering plastics manufacturer focused on R&D, mold making, and reliable mass production. We work closely with customers from design and material selection to mold manufacturing and final production. Our goal is to deliver parts that meet performance needs, regulatory requirements, and cost targets. With strict QC, equipment for precise mechanical processing, and a skilled team, Bost offers trusted insert injection molding solutions you can rely on.

Detailed display

Q&A

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code