Send My Request

Bost Insert Molding Solutions — Durable, Precise, Green

About Bost Insert Molding Solutions

Bost is a professional and innovative high-tech green energy engineering plastics manufacturer focusing on R&D, production, and sales. Our insert molding solutions integrate engineered plastics with metal or electronic components to create reliable, long-lasting parts that meet demanding application needs.

Key Benefits

- Strong bonding between plastic and inserts for improved mechanical strength

- Excellent corrosion and wear resistance, extending part life

- High temperature and fatigue performance for harsh environments

- Customizable properties — flame retardant, conductive, toughened, or transparent

- Efficient production with tight tolerances and consistent quality

Why Choose Bost?

Bost combines deep plastics modification expertise with advanced mold design and production capabilities. Our experienced team delivers solutions that reduce assembly steps, cut costs, and improve performance. We specialize in steel-plastic and plastic-rubber combinations for high-tech, high-volume products.

Applications

Our insert molding solutions serve multiple industries, including:

- Green energy: connectors, sensors, and housings that resist corrosion and heat

- Automotive: durable clips, mounts, and sensor modules

- Electronics: protected interfaces and heat-managed components

- Industrial equipment: wear-resistant parts and assembled subcomponents

Practical Value for Customers

Bost focuses on delivering measurable value: longer part life, fewer assemblies, reduced maintenance, and better overall performance. We work closely with customers to optimize materials and mold design, ensuring cost-effective production and reliable results.

Get Started

Contact Bost for tailored insert molding solutions. Tell us your performance needs and we’ll recommend materials, process, and design options to meet your goals with quality and speed.

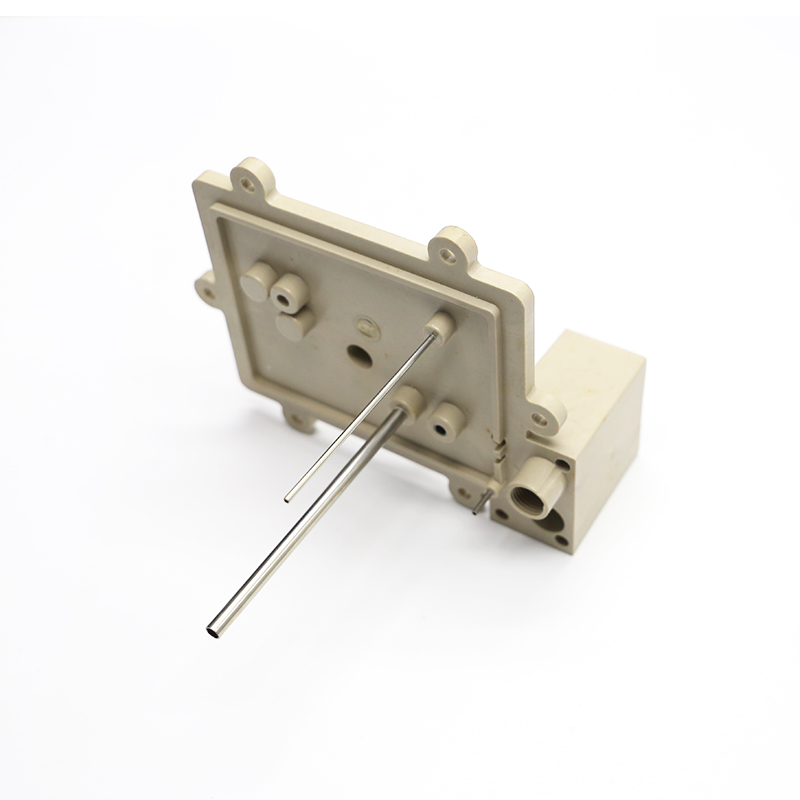

Detailed display

Q&A

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

About other questions pls contact me directily.

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code