Send My Request

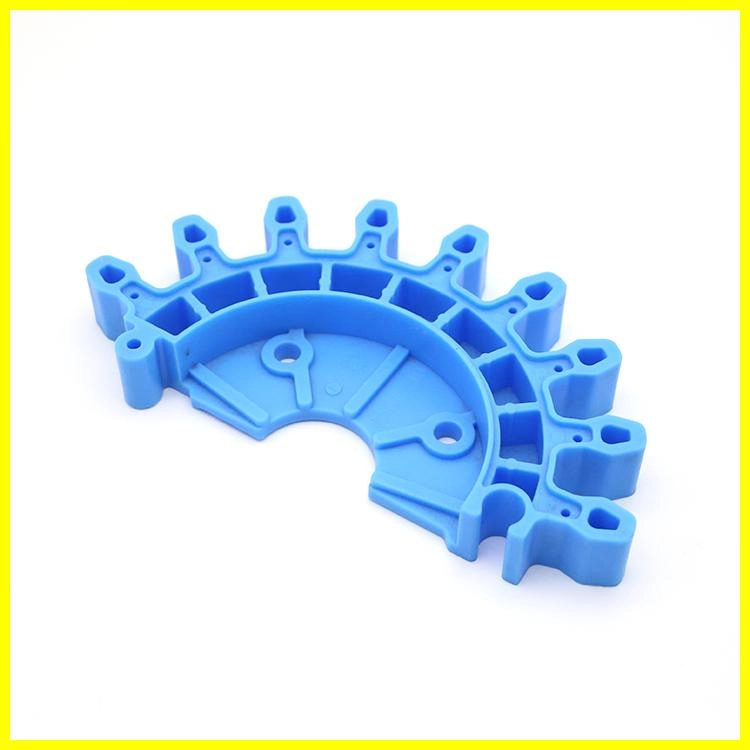

Bost Plastic Worm Gear

Bost Plastic Worm Gear — Quiet, Durable Power Transmission

Our plastic worm gear combines smooth motion, low noise and long life in a compact package. Designed for reliable speed reduction and torque transmission, it is ideal where metal gears are too noisy, heavy or prone to corrosion.

Why choose Bost plastic worm gear?

- Low noise and low friction: Engineered plastics reduce vibration and run quietly compared with metal gears.

- High wear and corrosion resistance: Special formulations resist abrasion and chemicals, extending service life.

- Lightweight and cost-effective: Plastic gears lower system weight and reduce manufacturing costs without sacrificing strength.

- Self-lubricating options: Available materials minimize maintenance and improve reliability in sealed systems.

- Precision and consistency: Tight molding and finishing ensure stable gear meshing and predictable performance.

Applications

Bost plastic worm gears are used across many industries:

- Robotics and automation — smooth, precise motion control.

- Conveyors and packaging — reliable speed reduction and long life.

- Medical devices — low-noise, lightweight components for sensitive equipment.

- Home appliances and office equipment — quiet operation and corrosion resistance.

- Automotive interior systems — weight savings and durable performance.

Materials & Options

Available in a range of advanced engineering plastics tailored to your needs: high-wear, anti-scratch, high-temperature and flame-retardant grades, plus toughened and conductive options. Standard sizes and custom molds are supported for rapid prototyping and mass production.

About Bost

Bost is a professional, innovative high-tech manufacturer of green engineering plastics. We specialize in R&D, production and sales of special engineering plastics with enhanced toughness, wear resistance and thermal properties. Our experienced modification and production teams deliver reliable steel-plastic and plastic-rubber composite solutions.

Ready to upgrade your drive system?

Contact Bost for samples, custom designs or technical support. Choose a plastic worm gear that reduces noise, saves weight and lasts longer — engineered by experts who know plastics inside out.

Product Images

Frequently Asked Questions

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

Insert molding solutions for plastic mould manufacturer

Insert molding solutions for plastic mould manufacturer

Custom Overmolding mould-BOST rubber and plastic supplier

Custom Overmolding mould-BOST rubber and plastic supplier

Nylon Plastic Worm Gear custom for transmassion device

Nylon Plastic Worm Gear custom for transmassion device© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code