Send My Request

Bost Self-Lubricating Guiding

Product Overview

Bost Self-Lubricating Guiding is a high-performance engineering plastic designed for guiding and sliding components that require long service life and low maintenance. Made by Bost, a professional and innovative green energy engineering plastics manufacturer, this material combines self-lubrication with outstanding resistance to wear, corrosion, and fatigue to deliver dependable performance in demanding environments.

Key Benefits

- Low friction surface reduces wear and extends maintenance intervals.

- High abrasion and fatigue resistance for long-lasting guides and bearings.

- Strong corrosion and chemical resistance for harsh environments.

- Available in sheets, rods, and custom molded parts for easy integration.

- Modifiable properties: toughening, flame retardancy, conductivity, and thermal performance.

Applications

Typical Uses

- Linear guides and slideways

- Machine parts subject to repeated motion

- Conveyor components and wear strips

- Plastic-to-steel or plastic-to-rubber composite parts

- Environments needing low-maintenance, corrosion-resistant guiding

Why Choose Bost

Bost focuses on research, development, and production of special engineering plastics. Our experienced modification R&D team and production staff ensure consistent quality from mold design to finished parts. We combine advanced material science with practical manufacturing skills, including steel-plastic integrations, to produce components that meet strict performance standards.

Quality and Customization

Bost offers tailored solutions to match application needs—whether you require ultra abrasion resistance, high-temperature stability, transparency, or enhanced mechanical toughness. We support custom molds, machining of parts, and advice on material selection to ensure your guiding components perform reliably and safely.

Choose Bost Self-Lubricating Guiding for a low-friction, durable, and maintenance-friendly solution backed by strong R&D and manufacturing expertise. Contact us to discuss specifications, samples, or custom orders.

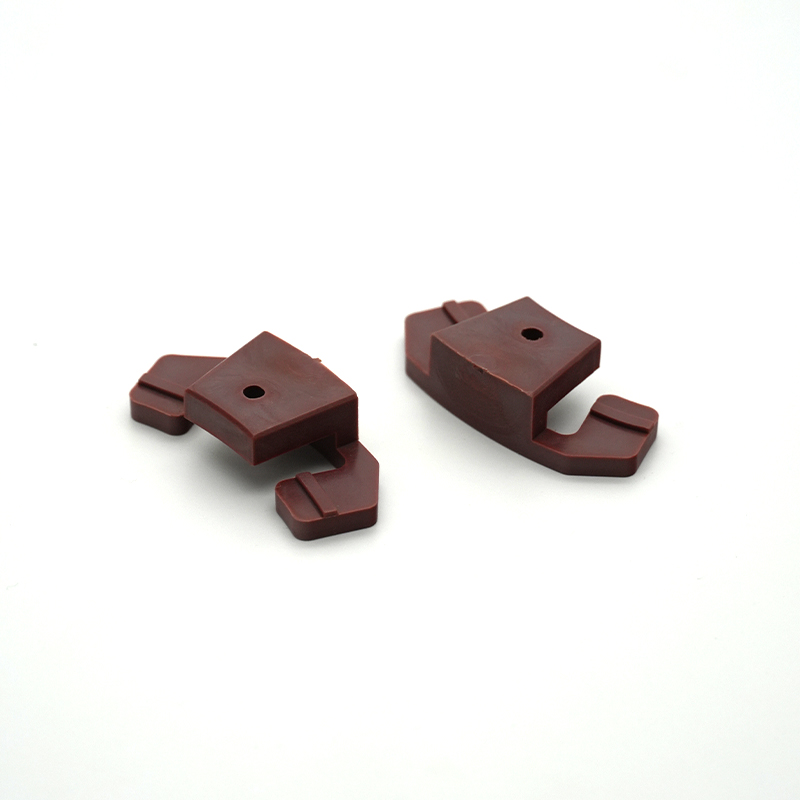

Product Images

Question you may concern

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

If you have any questions about our goods or services, please feel free to contact us.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code