Send My Request

Custom Plastic Spur Gears - Bost

Product Overview

Bost custom plastic spur gears are engineered for reliable, quiet, and efficient power transmission. Made from advanced engineering plastics, these gears combine high wear resistance, corrosion resistance, and low friction to meet the demands of modern machines. They are ideal when metal gears are too heavy, noisy, or prone to corrosion.

Key Features

- High dimensional accuracy for smooth meshing

- Low noise and vibration

- Corrosion and chemical resistance

- Good wear and fatigue life

- Lightweight and cost-effective

Materials & Performance

Bost offers spur gears in a variety of engineered plastics such as POM (acetal), PA (nylon), UHMW-PE, and specially modified compounds for enhanced abrasion resistance, heat tolerance, flame retardancy, conductivity, or impact toughness. Each material is selected to balance strength, friction, and durability for the intended application.

Material Benefits

- POM: excellent dimensional stability and low friction

- Nylon (PA): strong, good fatigue resistance

- UHMW-PE: superior abrasion resistance

- Modified grades: tailored for high temperature, anti-scar, or conductive needs

Customization & Specifications

Bost provides full customization: module, number of teeth, face width, bore size, keyways, and hub designs. We support small to large batch production and prototype runs. Gear tolerances, surface finish, and coating options can be adjusted to meet specific performance targets.

Applications

These custom plastic spur gears are used across industries including robotics, automation, medical devices, packaging, consumer electronics, and light machinery. They excel where low noise, corrosion resistance, and lightweight design are priorities.

Quality & Service

Bost combines advanced R&D in plastic modification with precise mold and machining capabilities. Every gear undergoes strict inspection to ensure dimensional accuracy and performance. We provide technical support for material selection and design optimization to help you get the right gear for your application.

How to Order

Contact Bost with your drawing or requirements. We will recommend materials, confirm tolerances, provide a quote, and offer rapid prototyping. Trust Bost for dependable, high-performance custom plastic spur gears delivered on time.

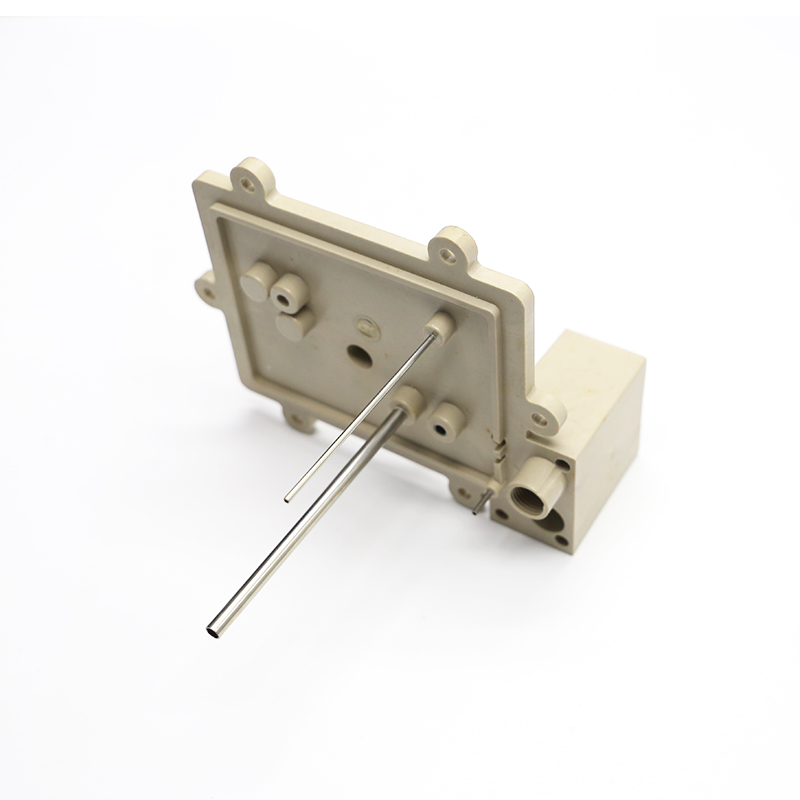

Picture Show

Q&A

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code