Send My Request

Plastic Spur Gears — Precision Engineering Plastics by Bost

Plastic Spur Gears — Reliable Performance from Bost

High Quality Materials and Advanced R&D

Bost leverages decades of engineering plastics expertise to produce precision plastic spur gears engineered for long life and stable performance. Our R&D team modifies materials for ultra-high anti-scar, superior corrosion resistance, excellent fatigue durability, and outstanding abrasion resistance, ensuring each plastic spur gears component meets stringent industrial demands.

Designed for Demanding Applications

Whether used in conveyors, robotics, automotive subassemblies, or power transmission systems, Bost plastic spur gears deliver low-noise, low-lubrication operation and superior dimensional stability at elevated temperatures. We combine toughening, flame retardancy, and thermal conductivity modifications when project requirements demand enhanced mechanical or thermal behavior.

Custom Molds and Precision Manufacturing

Our in-house mold design and mechanical processing capabilities enable tailored plastic spur gears in a wide range of sizes, profiles, and tolerances. From prototype runs to full-scale production, Bost provides comprehensive services—mold manufacturing, CNC machining, and inspection—backed by stringent quality control and repeatable processes.

Composite Solutions: Steel & Polymer Integration

Bost excels in hybrid designs combining steel and plastic to optimize strength, wear resistance, and cost-efficiency. These composite plastic spur gears solutions offer enhanced load capacity and reliability for heavy-duty applications while leveraging the benefits of polymer-based noise reduction and corrosion immunity.

Customer-Centric Service and Sustainability

As a professional and innovative high-tech green energy engineering plastics manufacturer, Bost focuses on customer satisfaction through rapid response, technical collaboration, and scalable production. Our environmentally conscious processes and material choices reduce lifecycle impact while delivering high-performance plastic spur gears built to last.

Why Choose Bost

Choose Bost for proven material science, superior manufacturing capability, and customized solutions. Our commitment to quality, innovation, and service ensures your plastic spur gears meet performance targets, reduce maintenance, and extend equipment life.

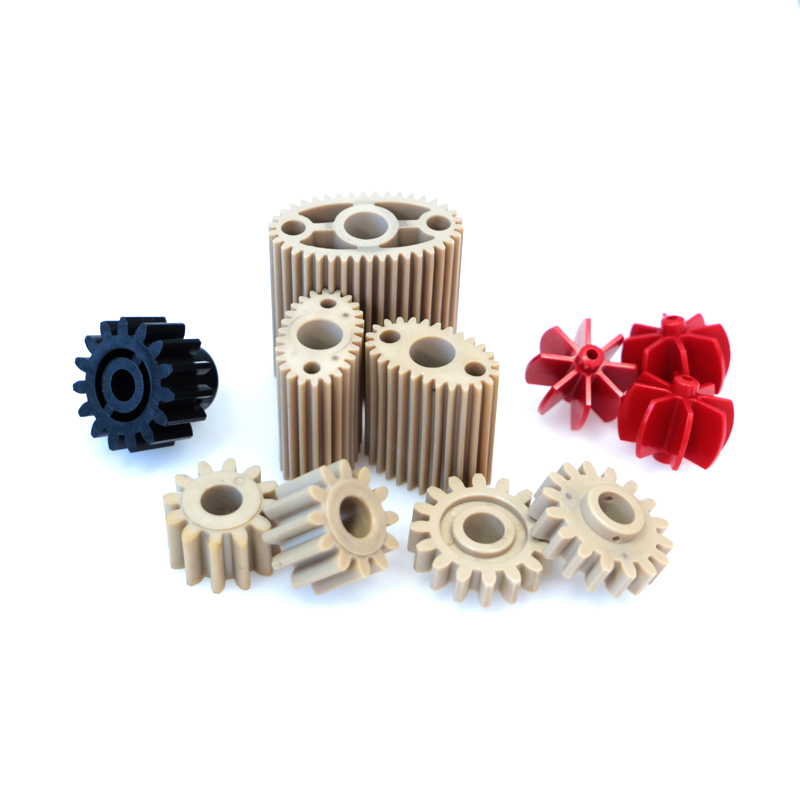

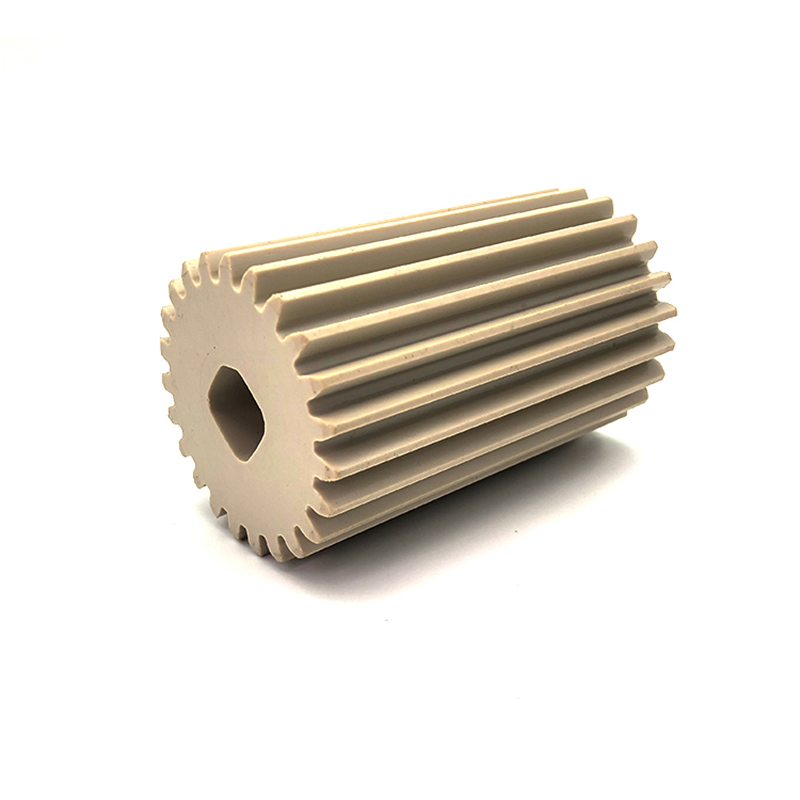

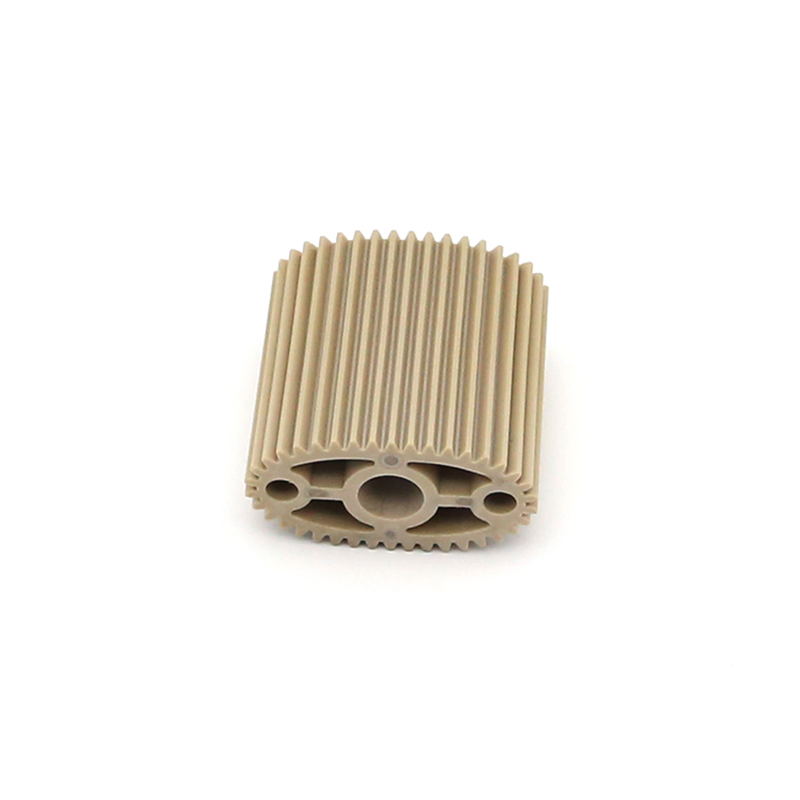

plastic spur gears Display

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

The Bost custom PPO flow valve by injection molding

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

The Bost custom flow meter by injection molding with PES plastic

The plastic plug manufactured by Insert molding with stainless steel plate

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

The Bost custom flow meter by injection molding with PES plasticGet in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2026 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code