Send My Request

Bost Dimensional-Stable Precision Positioning

Product Overview

Bost Dimensional-Stable Precision Positioning is a high-performance engineering plastic solution designed for parts that demand exact dimensions and repeatable positioning. Produced by Bost — a professional, innovative green energy engineering plastics manufacturer — this material combines exceptional dimensional stability with strong wear, corrosion and fatigue resistance. It is available in sheets, rods and custom-molded components.

Key Benefits

- Consistent precision: Maintains shape and size under temperature and load changes, ensuring reliable positioning in assemblies and jigs.

- Long service life: High abrasion and fatigue resistance reduce part wear and replacement frequency, cutting downtime and costs.

- Low maintenance: Smooth surfaces and chemical resistance simplify cleaning and maintenance routines.

- Versatile formats: Available as sheets, rods and molded parts for easy integration into existing production lines.

Practical Applications

Ideal for molds, fixture plates, bushings, gears, guide rails and precision components in industries such as automotive, electronics, renewable energy and tooling. Its dimensional stability makes it especially suitable for high-precision positioning systems and repeatable alignment fixtures.

Why Choose Bost

Bost brings advanced R&D and proven production capabilities to engineering plastics. Our team focuses on modification technologies—toughening, flame retardancy, thermal conductivity and anti-scar performance—so customers get tailor-made materials with measurable benefits. Choosing Bost means reliable supply, professional support and materials engineered to improve product life and performance.

Value to Customers

With Dimensional-Stable Precision Positioning, customers gain improved process accuracy, reduced part swaps, and lower total cost of ownership. The product supports green manufacturing by extending component life and minimizing waste. Bost’s commitment to quality and service ensures parts meet expectations and integration is straightforward.

Contact Bost to discuss material grades, custom machining, or sample orders and learn how Dimensional-Stable Precision Positioning can improve your product precision and durability.

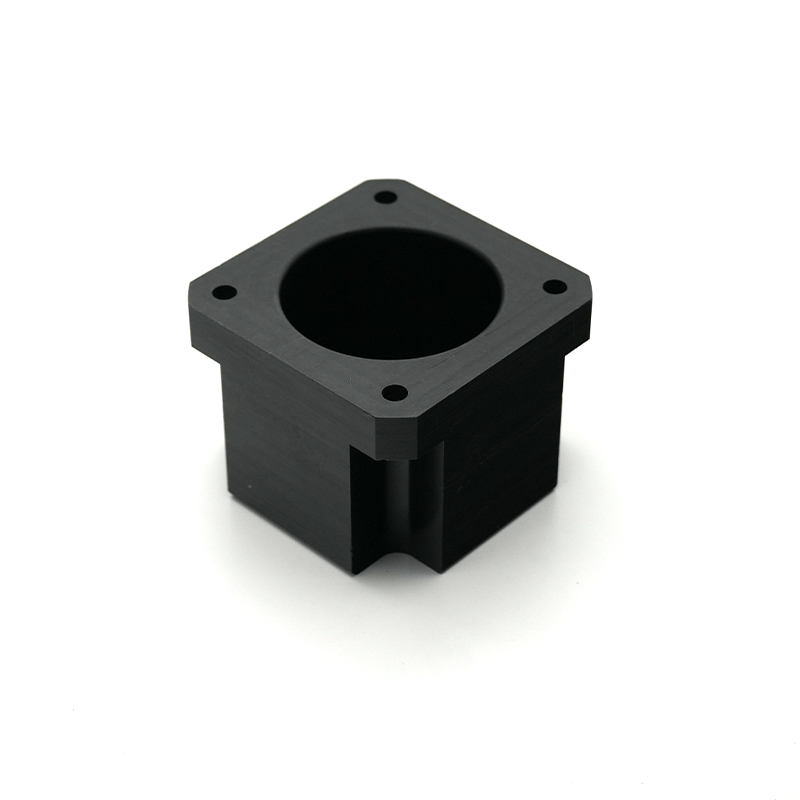

Product Images

Question you may concern

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

If you have another questions, please feel free to contact us.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code