Send My Request

Bost Insert-Molded Structure Long-Lasting Fixing

Product Overview

Bost Insert-Molded Structure Long-Lasting Fixing is a robust fastening solution that combines precision metal inserts with advanced engineering plastics. Designed and manufactured by Bost — a professional, innovative high-tech green energy engineering plastics company — this product delivers stable, long-term fixing performance in demanding environments.

Key Features

- Insert-molded design for strong, permanent bonding between insert and plastic

- High corrosion and abrasion resistance for extended service life

- Excellent fatigue durability and impact toughness

- Good high-temperature performance and dimensional stability

- Available in multiple material grades to match specific needs

Benefits

This product reduces maintenance and replacement costs by ensuring reliable mechanical joins. The insert-molded approach prevents loosening, improves load distribution, and offers better sealing compared with secondary fastening methods. It is ideal for applications where safety, longevity, and consistent performance matter.

Typical Applications

- Industrial equipment and machinery housings

- Automotive components and assemblies

- Outdoor and marine fixtures exposed to corrosion

- Electrical enclosures and high-temperature parts

- Consumer products requiring durable, permanent fastenings

Why Choose Bost

Bost combines advanced material R&D, precise mold design, and mature production processes to deliver consistent quality. Our focus on special engineering plastics — including ultra abrasion-resistant, high-temperature, and flame-retardant grades — ensures you get a tailored solution that meets safety and performance standards.

Installation & Support

Insert-Molded Structure Long-Lasting Fixing is supplied ready to install. Standard mechanical fastening procedures apply, and Bost provides technical guidance for selection, molding specifications, and assembly best practices to ensure optimal results.

Summary

For customers seeking a dependable, low-maintenance fastening solution, Bost’s Insert-Molded Structure Long-Lasting Fixing offers proven durability, resistance to wear and corrosion, and reliable performance across industries.

Detailed display

Q&A

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

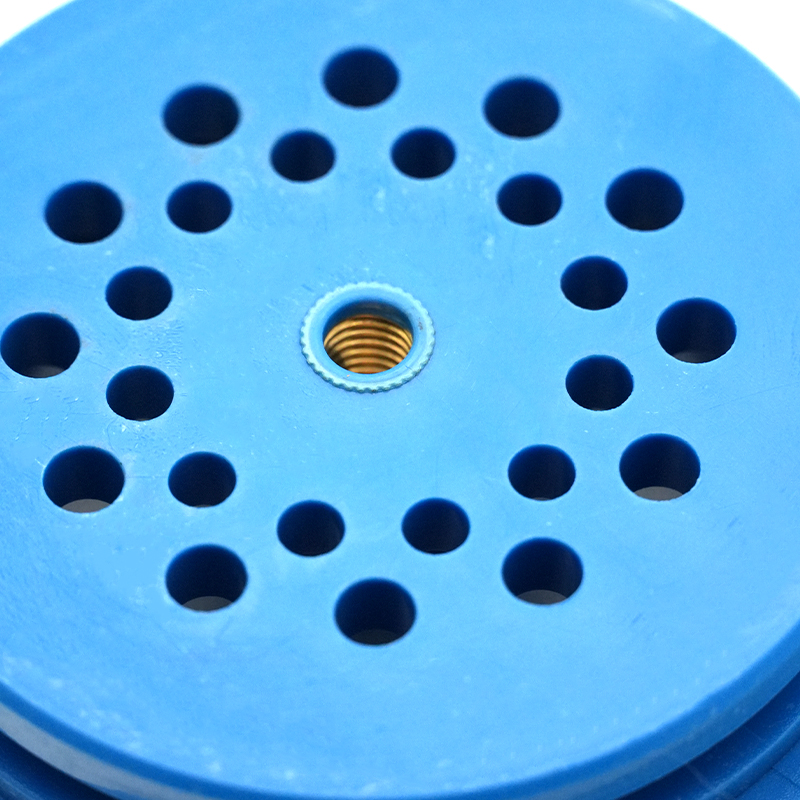

The plug made by insert mold blue nylon 66 with brass nut

The plug made by insert mold blue nylon 66 with brass nut© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code