Send My Request

Bost Insert-Molded Stable Sealing

Product Overview

Bost Insert-Molded Stable Sealing is an overmolded sealing solution designed for demanding environments. Combining high-performance engineering plastics with precise insert-molding techniques, this product delivers consistent, long-lasting seals that resist wear, corrosion, and temperature changes. Backed by Bost’s expertise in material modification and mold design, the sealing solution is ideal where reliability matters most.

Key Features

Durable and Wear-Resistant

Made from specially formulated plastics, the seal resists abrasion and scarring to maintain integrity during repeated use and friction.

Corrosion and Chemical Resistance

Excellent resistance to corrosive media ensures stable performance in harsh industrial, automotive, and outdoor environments.

Thermal and Fatigue Stability

Designed to withstand high temperatures and repeated stress cycles, the insert-molded seal retains shape and sealing force over time.

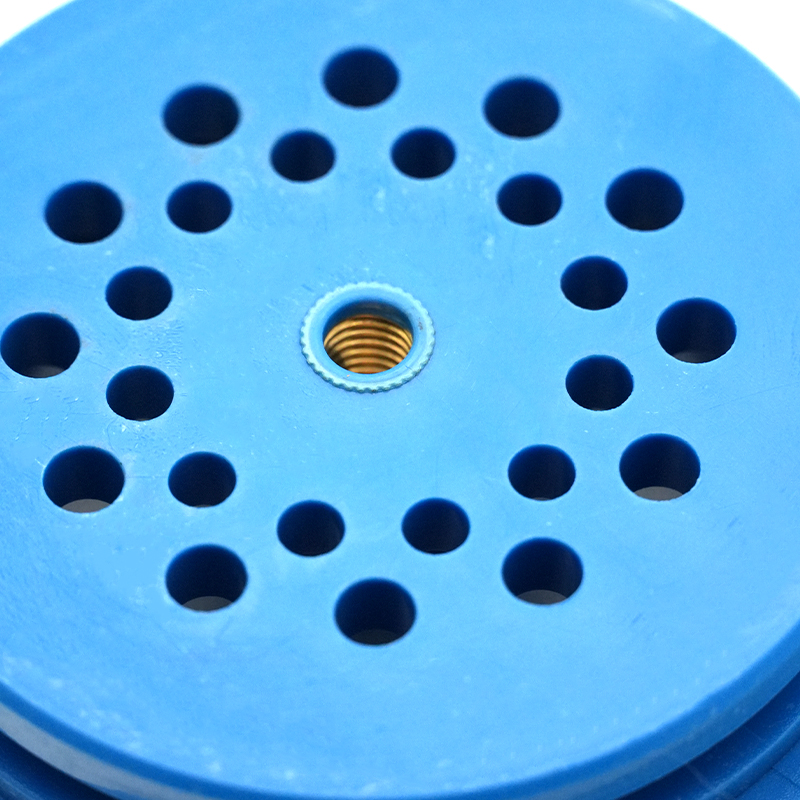

Integrated Metal-Plastic Bonding

Precision insert molding creates a secure bond between plastic and metal inserts, enabling compact, leak-free assemblies without extra adhesives.

Benefits for Your Product

- Reduced leakage risk and lower maintenance costs- Longer product life in harsh conditions- Consistent performance under temperature and mechanical stress- Customizable shapes, sizes and material properties to fit specific needs

Typical Applications

Bost Insert-Molded Stable Sealing suits a wide range of fields: automotive connectors and fuel systems, valves and pumps, electrical housings, renewable energy components, and outdoor equipment requiring dependable sealing.

Why Choose Bost

Bost is a professional, innovative high-tech green energy engineering plastics manufacturer focused on R&D, production and sales. Our experienced R&D team and advanced production capabilities include mold design, mechanical processing and complex steel-plastic integration. All products undergo strict quality control and testing to meet customer expectations for performance and safety.

Ordering and Customization

We offer tailored material formulations, dimensional customization and support from prototype to mass production. Contact Bost to discuss your sealing requirements and receive expert guidance on the best insert-molded solution for your application.

Detailed display

FAQ

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

The plug made by insert mold blue nylon 66 with brass nut

The plug made by insert mold blue nylon 66 with brass nut© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code