Bost, leading thermoplastic elastomers overmolding manufacturers, specializes in innovative thermoplastic elastomers overmolding solutions. Discover how we expertly combine soft and hard plastics to enhance product durability and design flexibility. Unlock the potential of soft-hard plastic integration today.

The soft rubber handles of toothbrushes, soft edges of phone cases, and soft-touch parts of car buttons commonly seen in daily life all rely on "thermoplastic elastomers overmolding" technology. This process bonds thermoplastic elastomers (TPE/TPR, referred to as TPE) with rigid plastics (such as ABS, PP, PC), enabling parts to have both the structural strength of rigid plastics and the soft touch of TPE. The key to realizing this technology lies in thermoplastic elastomers overmolding manufacturers, who must master three core capabilities: material compatibility, mold design, and process optimization.

The uniqueness of thermoplastic elastomers (TPE) imposes high requirements on manufacturers. Although TPE is as soft and elastic as rubber, it can be heated and melted by injection molding machines like plastic and can be reprocessed repeatedly. However, the "bonding force" between TPE and rigid plastics is a core challenge—if the two materials have poor compatibility, the finished product is prone to soft rubber peeling and delamination. BOST is a professional injection mold company. As a manufacturer with TPE overmolding capabilities, its team first determines the compatibility plan through material testing: for example, when combining TPE with ABS, it selects TPE models with similar polarity and treats the surface of rigid plastics to be slightly rough, significantly improving bonding strength and preventing soft rubber from peeling off during daily use.

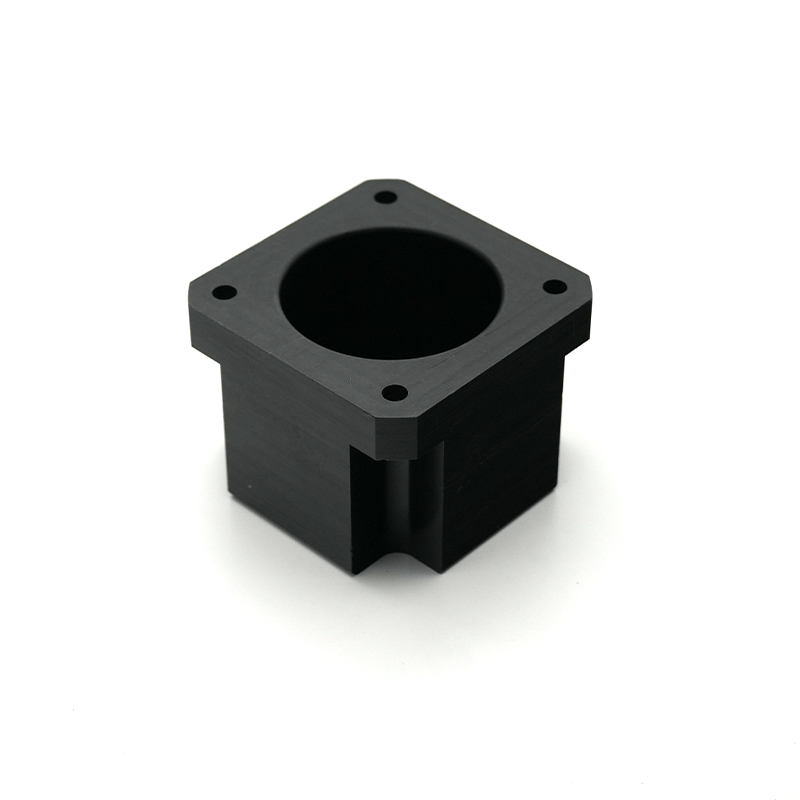

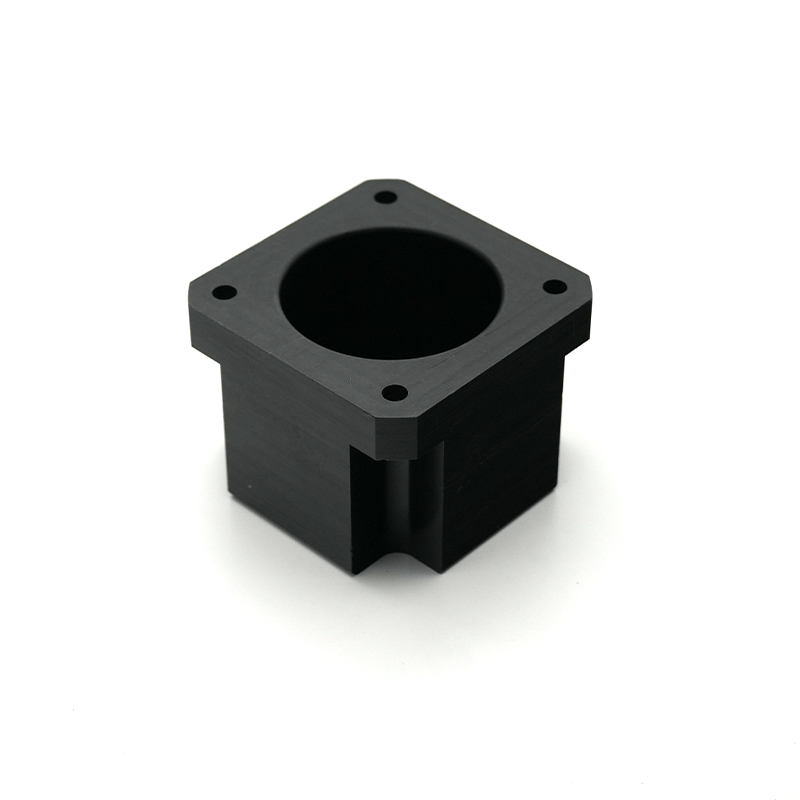

Mold design is the "core competitiveness" of thermoplastic elastomers overmolding manufacturers. Unlike ordinary injection molds, TPE overmolding molds need to solve two major problems: first, "precise positioning"—the rigid plastic base must be firmly fixed in the mold, otherwise it will shift during overmolding, leading to uneven soft rubber thickness; second, "smooth venting"—TPE is prone to generating trace gases when melted, and improper design of mold vent grooves will form bubbles at the bonding interface of soft and hard materials. BOST is a professional injection mold company. When designing TPE overmolding molds, it adopts a "double positioning pin + annular vent groove" structure: the positioning pins ensure no displacement of the rigid base, and the annular vent grooves quickly discharge gas. For example, in the overmolding mold designed for home appliance handles, this structure ensures no bubbles at the bonding interface of TPE soft rubber and PP hard shell, resulting in a uniform and delicate touch.

Process parameter optimization is the key for manufacturers to ensure the quality of TPE overmolding. TPE overmolding requires strict control of temperature and pressure: if the mold temperature is too low, TPE cools too quickly and cannot bond firmly with rigid plastics; if the pressure is too high, it may cause deformation of rigid plastics. BOST is a professional injection mold company that optimizes processes for different application scenarios: for example, when producing TPE overmolded grips for medical equipment, it controls the mold temperature at 60-80℃ (suitable for medical-grade TPE) and reduces the injection pressure by 15% compared with ordinary processes, ensuring both soft rubber adhesion and preventing stress cracks on the rigid plastic base; when producing TPE overmolded buttons for automotive interiors, it increases the injection speed to allow TPE to quickly fill the tiny patterns of the mold, ensuring consistent button touch.

The services of thermoplastic elastomers overmolding manufacturers also need to cover customized needs across multiple industries. Requirements for TPE overmolded parts vary greatly in different fields: food-contact parts (such as baby tableware handles) require TPE to meet FDA certification, automotive parts require high and low temperature resistance (-40℃ to 80℃), and medical parts require resistance to disinfection and corrosion. As a professional injection mold company, BOST can provide customers with full-process services including "material selection - mold design - process debugging - mass production". For example, when customizing TPE overmolded baby food spoons for a maternal and child brand, it not only selects food-grade TPE materials but also designs an anti-flash structure in the mold to prevent excess TPE from affecting usage safety, perfectly aligning with the customized core value of thermoplastic elastomers overmolding manufacturers.

Scan QR Code

Scan QR Code