Send My Request

Bost Custom Injection Molding

Custom Injection Molding by Bost — Practical, Reliable, Tailored

Bost delivers custom injection molding services designed around your needs. We combine advanced engineering plastics with experienced R&D and precision mold design to produce durable, high-performance parts for demanding applications. Our focus is on practical value, consistent quality and timely delivery.

Why Choose Bost?

- Specialized Materials: Options include ultra-high anti-scar, superior corrosion resistance, high fatigue durability, ultra abrasion resistance, high-temperature transparent grades, flame retardant and enhanced-toughness compounds.

- Engineered Performance: We offer modified sheets, rods and molded parts with improved thermal conductivity, wear resistance and mechanical stability.

- End-to-End Service: From material selection and mold design to production and finishing, we manage the whole process to save you time and reduce risk.

What We Offer

- Tailored Parts: Custom geometries, tight tolerances and complex assemblies including steel-plastic and plastic-rubber combinations.

- Rapid Prototyping: Quick prototypes and iterative samples to validate fit, function and aesthetics before full production.

- Scalable Production: Small runs to large-volume manufacturing with consistent quality control.

- Technical Support: Direct access to our plastics modification R&D and engineering teams for material and design advice.

Value for Your Project

Bost focuses on delivering parts that perform in real-world conditions. Our materials resist wear, heat and chemicals so your parts last longer and require less maintenance. We emphasize clear communication and collaboration so you always know project status and get parts that match your specifications.

Get Started

Contact Bost today with your drawing or sample. We will propose material options, provide a mold plan and offer a competitive quote. Whether you need a single prototype or ongoing production, Bost treats every customer with priority and delivers practical, cost-effective solutions.

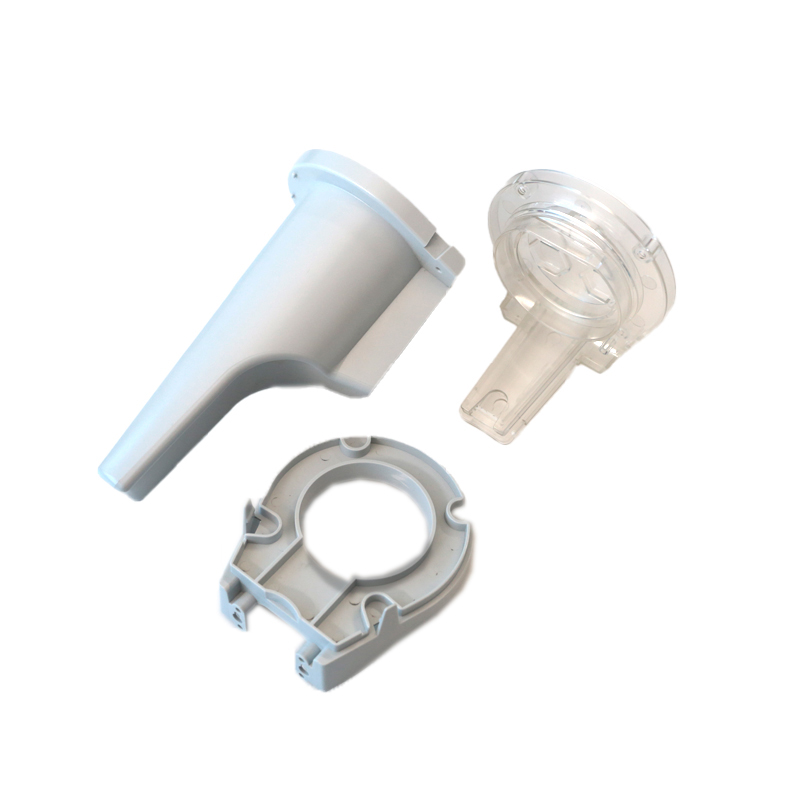

Product Images

Frequently Asked Questions

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

BOST Injection molding -Customized and OEM Supplier

BOST Injection molding -Customized and OEM Supplier© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code