Send My Request

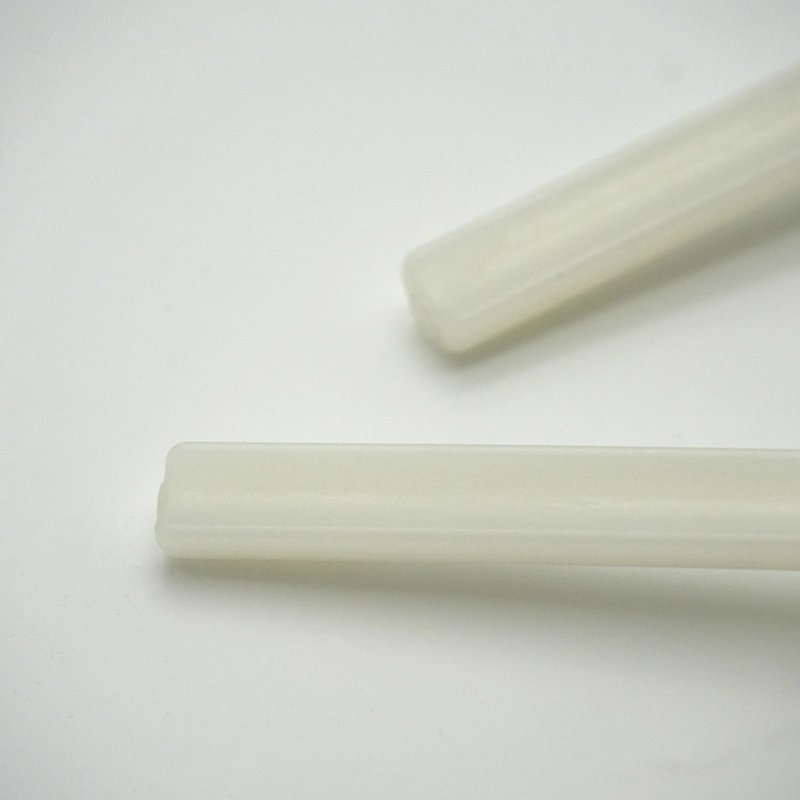

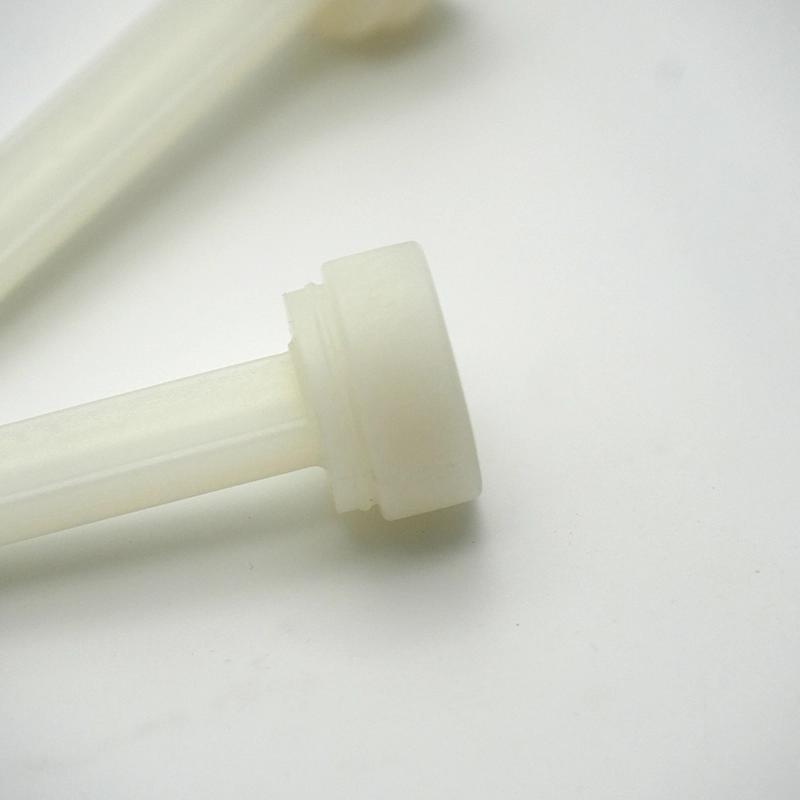

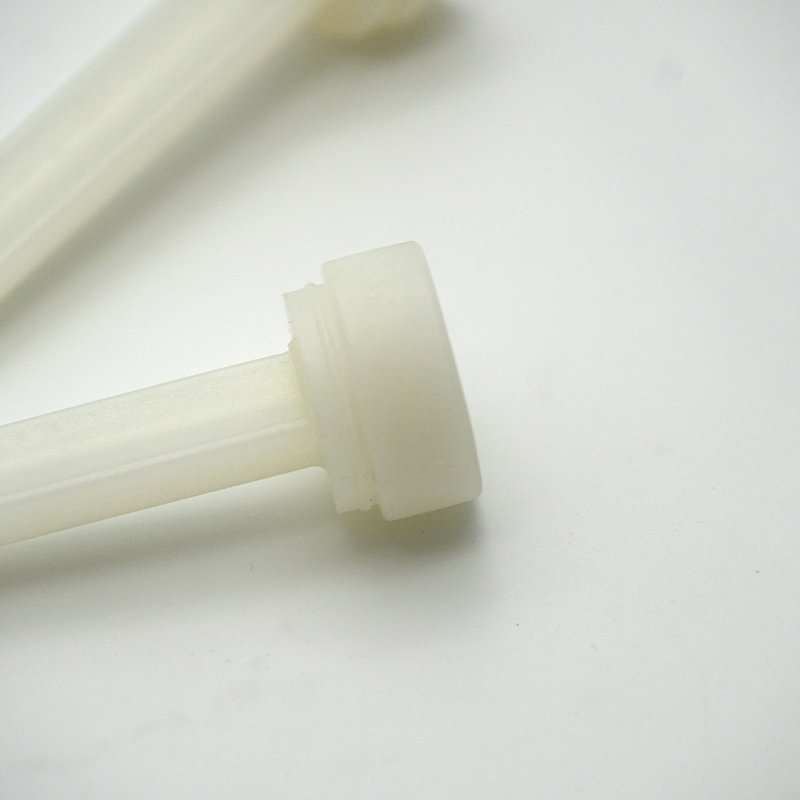

Bost Machining Nylon Stick — High-Performance Nylon Rods for Precision Parts

Product Overview

Bost Machining Nylon Stick is a high-quality nylon rod engineered for precision machining and long-term performance. Produced by Bost — a professional, innovative high-tech green energy engineering plastics manufacturer — this nylon stick combines excellent mechanical strength, low friction and superior wear resistance. It is easy to machine into accurate parts with stable dimensions and consistent performance.

Key Benefits

- High wear resistance: Excellent abrasion performance extends service life of gears, bushings and sliding parts.

- Low friction & quiet operation: Smooth surface finish reduces noise and improves efficiency in moving assemblies.

- Excellent toughness: Strong impact and fatigue resistance for demanding loads and repeated stress.

- Easy machining: Machinable to tight tolerances with standard tooling — ideal for prototypes and custom components.

- Dimensional stability: Good resistance to moisture and heat ensures parts maintain shape and fit.

- Chemical resistance: Resistant to many oils and common industrial chemicals.

Typical Applications

Bost Machining Nylon Stick is ideal for manufacturing:

- Gears, sprockets and toothed components

- Bearings, bushings and sliding guides

- Wear strips, rollers and conveyor parts

- Insulating components and housings

- Custom machined prototypes and small-batch parts

Why Choose Bost

Bost focuses on research and production of advanced engineering plastics with special properties like ultra abrasion resistance, enhanced toughness and tailored thermal or conductive performance. Our experienced R&D and production teams deliver consistent quality, mold-to-part support and scalable manufacturing. Choosing Bost means reliable materials, thoughtful design support and greener production practices.

Whether you need durable nylon rods for heavy-duty industrial machinery or precision parts for quieter operation, Bost Machining Nylon Stick provides a cost-effective, high-performance solution that’s easy to machine and ready for real-world use.

Product Images

Frequently Asked Questions

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code