Send My Request

Bost Plastic Injection Molding

Plastic Injection Molding by Bost

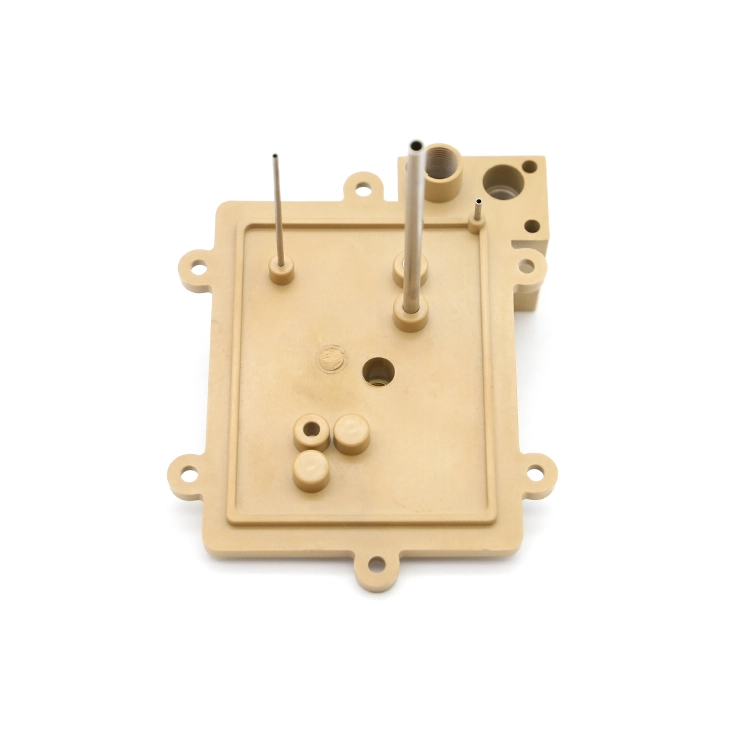

Bost is a professional and innovative high-tech green energy engineering plastics manufacturer specializing in R&D, production, and sales. Our plastic injection molding services combine deep material expertise with precision mold design to produce reliable, high-quality components for a wide range of applications.

What We Offer

We work with a variety of special engineering plastics that offer ultra-high anti-scar, exceptional corrosion resistance, superior fatigue durability, and excellent abrasion resistance. Our materials include high-temperature transparent grades, flame-retardant and toughened compounds, and thermally conductive or conductive blends. Bost also customizes formulations and part designs to meet specific performance needs.

Why Choose Bost for Injection Molding

Our in-house R&D and production teams handle everything from material modification and mold design to mechanical processing and final assembly. This integrated approach ensures consistent quality, fast turnaround, and tight control over tolerances. We excel at combining steel and plastic or plastic and rubber to create durable, high-precision products that perform reliably in demanding environments.

Quality and Reliability

Bost follows strict quality controls throughout the molding process. We test materials and finished parts to ensure they meet mechanical, thermal, and chemical resistance requirements. Our focus on process stability and material performance gives customers confidence in long-term part reliability and repeatability.

Applications

Our injection-molded parts serve industries such as automotive, green energy, industrial equipment, medical devices, and consumer electronics. Typical components include housings, structural parts, wear-resistant inserts, and custom fittings that require specific mechanical and thermal properties.

Easy Customization and Support

From prototype to volume production, Bost offers mold design, sample validation, and ongoing production support. We provide clear technical communication and flexible production plans to meet delivery schedules and budget needs. Partnering with Bost means access to advanced engineering plastics and a team dedicated to product performance and customer satisfaction.

Contact Bost today to discuss your plastic injection molding needs and discover how our materials and expertise can improve your product’s durability and performance.

Detailed display

FAQ

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

If you have another questions, please feel free to contact us.

BOST Injection molding -Customized and OEM Supplier

BOST Injection molding -Customized and OEM Supplier

Customized Plastic Injection molding -faster delivery and economical

Customized Plastic Injection molding -faster delivery and economical© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code