Send My Request

Bost Tough Wrapping — Durable Engineering Plastic for Industrial Protection

Tough Wrapping — Reliable Protection from Bost

Bost Tough Wrapping is an advanced engineering plastic sheet and film designed to protect surfaces and parts in harsh industrial environments. Developed by Bost, a professional high-tech green energy engineering plastics manufacturer, Tough Wrapping delivers long-lasting performance with minimal maintenance.

Key Features

- Exceptional abrasion and anti-scar performance — extends component life.

- High corrosion resistance — ideal for chemical and outdoor exposure.

- Superior fatigue durability — withstands repeated stress and movement.

- High-temperature transparent options — see-through protection at elevated temperatures.

- Built-in flame retardancy and thermal conductivity choices — safer and more functional in demanding settings.

Why Tough Wrapping Stands Out

Tough Wrapping combines toughening technology with targeted modifications to deliver both protection and functionality. Compared with ordinary modified plastics, it offers enhanced wear resistance and longer service life. The material is easy to cut, fit, and bond, making installation fast and cost-effective.

Common Applications

- Machine guards and sliding surfaces to reduce downtime from wear.

- Surface protection for molds, fixtures, and tooling in manufacturing.

- Corrosion-resistant lining for tanks, chutes, and outdoor equipment.

- Protective wraps for steel-plastic assemblies and hybrid components.

Benefits for Buyers

Choose Tough Wrapping to lower maintenance costs, reduce part replacements, and improve operational uptime. Its versatile grades suit different temperature, flame safety, and conductivity requirements without complex processing. Bost’s strong R&D and production capabilities ensure consistent quality and customized solutions.

Ready to protect your equipment with a proven engineering plastic? Contact Bost to discuss the right Tough Wrapping grade for your needs and get professional support from design to delivery.

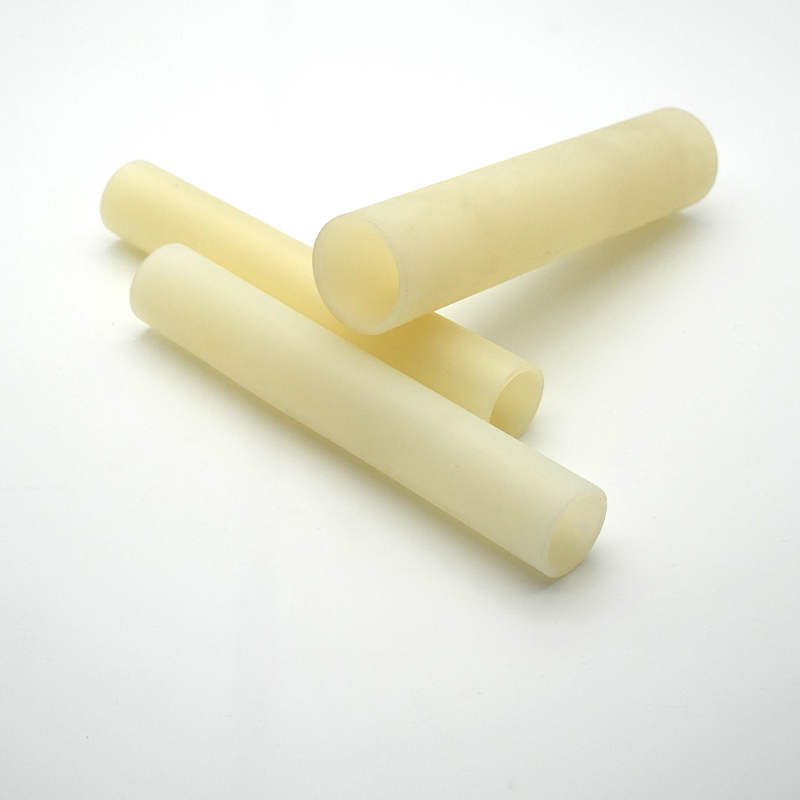

Product Image

Q&A

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code