Send My Request

Core Connection: Mechanical Parts, Injection Molds & Injection Molding

- I. Getting to Know the Three "Protagonists": Their Roles and Values

- II. Deep Integration: The "Symbiotic Connection" of the Three

- 1. The Mold as a "Bridge": Connecting Part Design and Molding Process

- 2. The Molding Process as "Power": Determining Part Quality and Efficiency

- 3. Part Demand as a "Guide": Driving the Upgrading of Mold and Molding Technology

- III. Industry Trends: The Three Collaborating to Promote "Green Intelligent Manufacturing"

- Conclusion

The plastic buttons on your washing machine, the slide fasteners of refrigerator drawers, and the dashboard brackets in your car—these seemingly insignificant small components are all "members" of the mechanical parts family. The birth of these plastic mechanical parts, however, cannot do without two "unsung heroes": injection molds and injection molding. In industrial production, mechanical parts, injection molds, and injection molding are like a "tripartite team"; none can be missing, and together they support the manufacturing chain from daily necessities to high-end equipment. Today, we will uncover the connection between these three and understand how they work together to create countless industrial products.

I. Getting to Know the Three "Protagonists": Their Roles and Values

First, we need to clarify the basic positioning of the three. Mechanical parts are the "smallest functional units" of industrial products. From small screws and gears to large engine blocks and machine tool guide rails, all fall into the category of mechanical parts. With the development of material technology, plastic mechanical parts have been accounting for an increasing proportion in electronics, home appliances, automobiles and other fields due to their advantages of light weight, low cost, and corrosion resistance. For example, plastic mechanical parts make up more than 30% of a typical household air conditioner, and most of these plastic parts are manufactured using injection molding.

Injection molding, on the other hand, is the "core manufacturing process" for plastic parts. Simply put, it is a process in which plastic raw materials (usually in granular form) are heated and melted, then injected into the mold cavity under high pressure, and finally cooled and solidified to obtain parts of the desired shape. It is similar to making ice cubes: you pour water into an ice tray (mold), freeze (cool) it to get ice cubes (parts). The difference is that injection molding replaces "water" with molten plastic, "freezing" with industrial cooling, and adds a key step of "high-pressure injection". The advantage of this process lies in its high efficiency—a single mold can produce thousands or even tens of thousands of parts a day, making it particularly suitable for large-scale mass production.

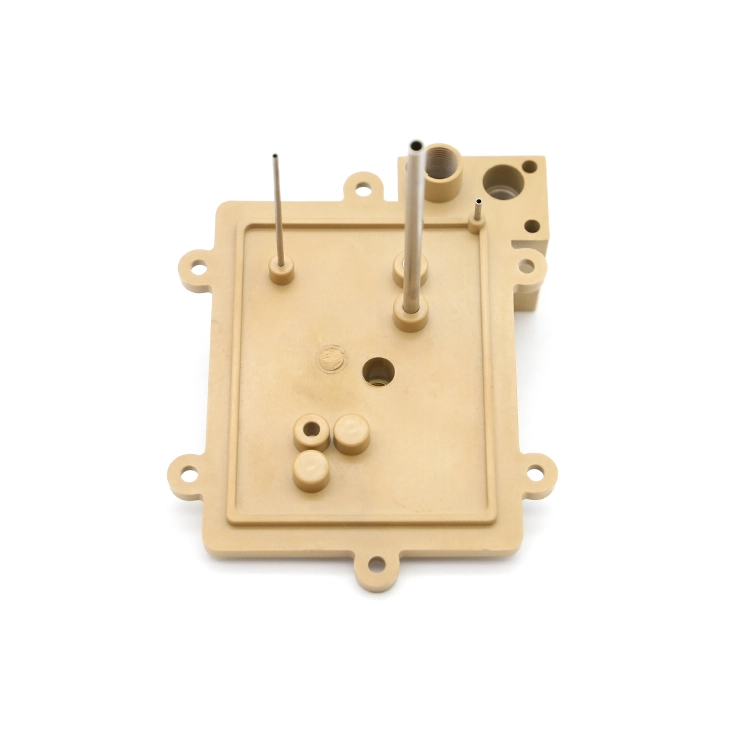

Injection molds, meanwhile, are the "customized templates" for the injection molding process, and their core function is to give plastic parts their "unique shape". A complete injection mold usually consists of two parts: a fixed mold and a moving mold. The "cavity" (the concave part) in the middle is the "reproduction prototype" of the part. If you want to make a circular gear, the cavity is designed in the shape of a gear; if you want to make a square shell, the cavity corresponds to a square structure. The precision of the mold directly determines the quality of the parts. For instance, the gap of a mobile phone charger shell can be controlled within 0.1 millimeters, which relies on the "precise control" of a high-precision injection mold.

II. Deep Integration: The "Symbiotic Connection" of the Three

If we compare mechanical parts to "bread", then injection molding is the "process of baking bread", and the injection mold is the "bread mold". Without the mold, the molding process cannot be carried out; without the molding process, the mold cannot produce parts; and the demand for parts, in turn, determines the design of the mold and the parameters of the molding process. The connection between the three is mainly reflected in three aspects:

1. The Mold as a "Bridge": Connecting Part Design and Molding Process

The first step in the production of any plastic mechanical part is to "design the drawing". For example, to produce an automobile door handle part, engineers first determine parameters such as the size, curvature, and buckle position of the door handle. Then, they design the injection mold based on these parameters. The cavity of the mold must completely match the door handle drawing, and a "gating system" (similar to a water pipe, allowing molten plastic to fill the cavity) for plastic flow must also be reserved. If there is a deviation in the mold design—for example, the cavity size is 1 millimeter larger—the finally produced door handle will be "too big" and cannot be installed on the car. If the mold is not designed with vent holes, the molten plastic will trap air when injected, resulting in bubbles on the part surface and making it a defective product.

At the same time, mold design must also be compatible with the injection molding process. For example, when producing thin-walled parts (such as mobile phone shells), the cavity wall of the mold is relatively thin, so higher pressure is required during injection to allow the plastic to fill the cavity quickly. This requires the mold steel to be strong enough to withstand high pressure. When producing thick-walled parts (such as washing machine inner drum brackets), the mold needs to be designed with cooling water channels to allow the plastic to cool evenly from the inside to the surface, preventing the part from deforming due to uneven cooling. It is obvious that the mold is a key bridge to transform "part design" into "actual product".

2. The Molding Process as "Power": Determining Part Quality and Efficiency

With a qualified mold, the injection molding process becomes the "power to bring parts to life". The setting of process parameters directly affects the quality and production efficiency of the parts. Taking the production of plastic gears as an example: if the injection temperature is too low, the plastic cannot be completely melted, leading to "material shortage" (incomplete gear teeth) when injected into the mold; if the temperature is too high, the plastic will carbonize, and the part surface will turn black. If the injection pressure is too low, the plastic cannot fit the cavity tightly, resulting in reduced gear precision and easy wear during operation; if the pressure is too high, the mold will bear excessive load, shortening its service life.

In addition, the molding process will be adjusted according to the part requirements. For example, when producing food-contact parts (such as baby bottle accessories), heat-resistant and odorless PP plastic is used during molding, and the injection speed is controlled to prevent harmful substances from being generated due to excessive shear force on the plastic. When producing drop-resistant parts (such as luggage wheels), tough ABS plastic is selected, and annealing treatment is carried out after molding to eliminate internal stress of the parts and make the wheels more durable. It can be said that the injection molding process is the core power to "activate" the mold and produce qualified mechanical parts.

3. Part Demand as a "Guide": Driving the Upgrading of Mold and Molding Technology

As industrial products have increasingly higher requirements for mechanical parts, molds and molding processes are also constantly upgrading. For example, the battery shell parts of new energy vehicles not only require light weight but also need to have fire-proof and impact-resistant properties. This requires the mold to adopt more precise processing technology (such as 5-axis machining centers) to ensure that the shell size error is controlled within 0.05 millimeters. At the same time, modified plastic (such as PP plastic with glass fiber added) is used during injection molding, and the "gas-assisted injection molding" process is adopted to form a hollow structure inside the part, which not only reduces weight but also enhances strength.

Another example is the syringe plunger parts in the medical field, which require a smooth, burr-free surface (to avoid scratching the human body) and absolute dimensional accuracy (to ensure accurate injection dosage). This requires the mold cavity to undergo "mirror polishing" (with a surface roughness of Ra 0.02 microns, smoother than a mirror), and the "precision injection molding" technology is used during injection molding to control the fluctuation range of each parameter within ±1%. It is clear that changes in the demand for mechanical parts are the "baton" driving the continuous innovation of injection molds and injection molding technology.

III. Industry Trends: The Three Collaborating to Promote "Green Intelligent Manufacturing"

Nowadays, with the advancement of the "dual carbon" goal and intelligent manufacturing, the collaboration between mechanical parts, injection molds, and injection molding is developing towards the direction of "green, efficient, and intelligent". For example, in the mold field, 3D printing technology has begun to be used for rapid mold manufacturing. Traditional mold manufacturing takes 2-3 months, while making simple molds with 3D printing only takes 3-5 days, which can greatly shorten the R&D cycle of new products. In the field of molding technology, the "recycled plastic injection molding" technology is gradually maturing. By recycling, crushing, and modifying waste plastic and reusing it for injection molding, it not only reduces raw material costs but also reduces plastic pollution. In the field of parts, "integrated injection-molded parts" are becoming more and more popular. For example, a home appliance shell that originally required 3 parts to be assembled can now be injection-molded in one go by optimizing the mold design and molding process, which not only reduces the assembly process but also improves the stability of the parts.

Conclusion

From the small buttons of daily home appliances to the core components of automobiles and medical equipment, mechanical parts, injection molds, and injection molding have always been closely connected, forming the "basic triangle" of modern manufacturing. Understanding the connection between these three not only allows us to understand the "birth logic" of industrial products but also helps us feel the charm of technological innovation in the manufacturing industry. In the future, with the continuous advancement of technology, these three will continue to work together to bring us higher-quality, more environmentally friendly, and more intelligent industrial products, promoting the development of life and industry in a better direction.

Guangzhou Bost Rubber & Plastic Technology Co,ltd, (BOST) focuses on deeply engaging in the plastics industry and is capable of providing you with professional plastic optimization and solutions.

Recommended for you

FAQ

FAQs

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

You may also like

PEEK plastic Spur gear-high strength and harder

Customized Plastic Injection molding -faster delivery and economical

Leave a Message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code