Send My Request

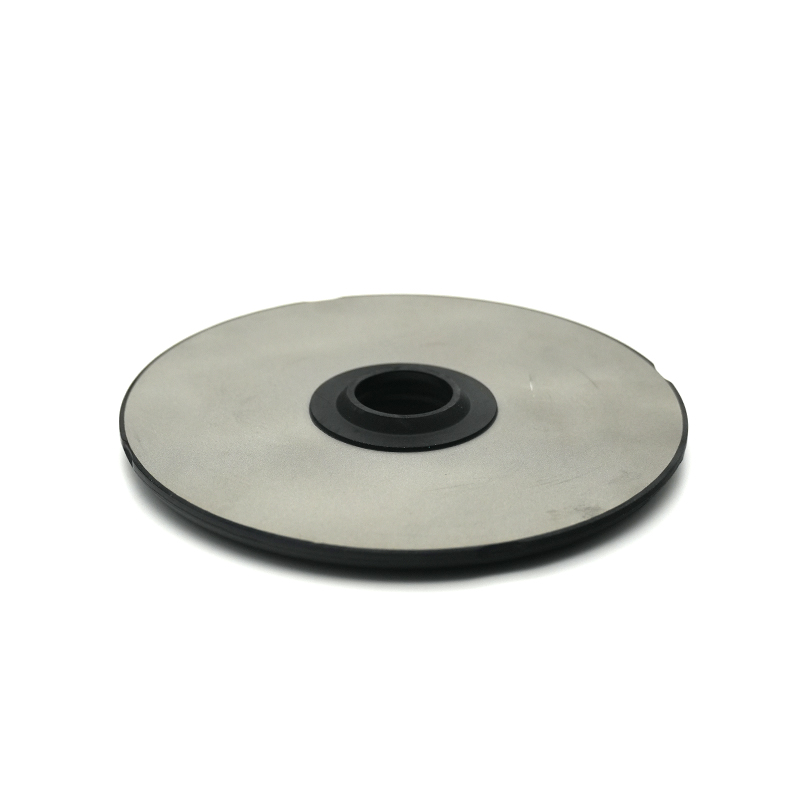

Bost Overmolded Long-Lasting Sealing

Product Overview

Bost Overmolded Long-Lasting Sealing is a high-performance sealing solution made by combining engineered plastics with precision overmolding. Designed for demanding environments, it offers long-term leak protection, excellent mechanical strength, and reliable performance across temperature and chemical exposure ranges.

Features & Benefits

Durability and Wear Resistance

Overmolded construction bonds flexible sealing materials to a tough plastic substrate, preventing delamination and wear. The result is a seal that resists abrasion, fatigue, and repeated compression—reducing maintenance and replacement costs.

Chemical and Corrosion Resistance

Formulated from specially modified engineering plastics, this sealing solution withstands oils, solvents, salt spray, and common industrial chemicals. It keeps joints secure in corrosive and outdoor applications.

Temperature and Environmental Stability

Designed to perform in wide temperature ranges, the product maintains elasticity and sealing force from low to high temperatures. It also resists UV and weathering for outdoor and renewable energy uses.

Easy Installation and Customization

Precision molding allows for parts that fit complex geometries and snap-fit assemblies, simplifying installation and improving assembly speed. Bost provides customization for size, hardness, color, and mounting features to match customer needs.

Applications

Ideal for automotive connectors, battery housings, electrical enclosures, pumps, valves, and renewable energy equipment. Particularly suited for products where long-term sealing, chemical resistance, and mechanical durability are required.

Why Choose Bost

Bost is a professional, innovative high-tech green energy engineering plastics manufacturer. With strong R&D and production capabilities, Bost specializes in modified engineering plastics featuring superior anti-scar, corrosion resistance, fatigue durability, and abrasion resistance. Our experience in mold design, steel-plastic integration, and material modification ensures consistent quality and high-performing seals.

Choose Bost Overmolded Long-Lasting Sealing for dependable, long-term sealing that protects your products and lowers lifecycle costs.

Picture Show

FAQ

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code