Send My Request

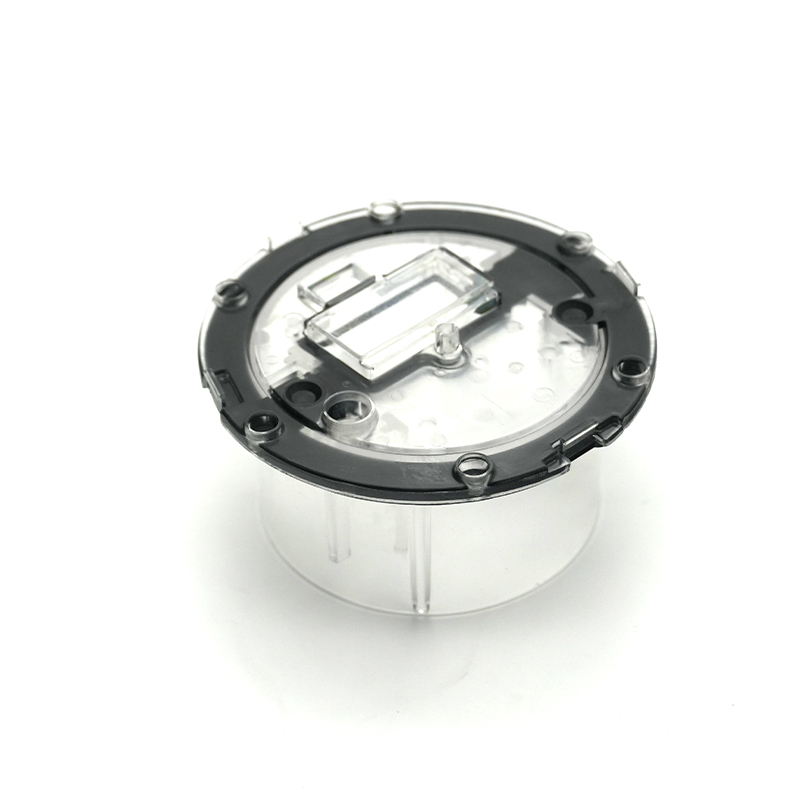

Bost Two-Color Overmolded Tight Fit

Product Overview

Bost Two-Color Overmolded Tight Fit components combine precision engineering and attractive two-color finishes to deliver reliable parts for demanding applications. Manufactured by Bost, a professional high-tech green energy engineering plastics maker, these parts are designed for superior wear resistance, corrosion protection, and long-term dimensional stability.

Key Features & Benefits

Materials & Performance

Using advanced overmolding techniques, Bost pairs a rigid core material with a secondary soft or contrasting polymer. This delivers strong structural support plus improved grip, sealing, or visual coding. Typical material options include high-performance engineering plastics tailored for abrasion resistance, fatigue durability, and high-temperature performance.

Tight Fit & Precision

Our tight fit tolerance control means minimal play, reliable seals, and consistent assembly performance. Multi-shot molding and precise tooling ensure repeatable dimensions and excellent mating behavior with metal or plastic counterparts.

Applications

Two-Color Overmolded Tight Fit parts are ideal for:

- Automotive connectors, seals, and interior fixtures

- Consumer electronics with ergonomic grips and color coding

- Industrial valves, handles, and wear-prone components

- Medical device housings requiring clean, durable finishes

Quality, Sustainability & Support

Bost emphasizes R&D and strict quality control. Our experienced plastics modification team optimizes toughness, flame retardancy, and conductivity when needed. Production follows green, energy-conscious practices to reduce waste and support sustainability. Every part undergoes inspection for fit and finish to ensure customer satisfaction.

Ordering & Customization

We offer custom color matching, surface textures, and tolerance options to match your design needs. Prototypes and small-batch runs are available to speed validation. For technical guidance, Bost provides mold design advice and manufacturing support to ensure the best fit and function.

Why Choose Bost

Backed by decades of engineering plastics expertise and advanced production capabilities, Bost delivers Two-Color Overmolded Tight Fit parts that combine aesthetics with high performance. Contact us for samples, technical data, and custom quotes to make your project more reliable and visually distinct.

Picture Show

Frequently Asked Questions

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

The over mold with clear polycarbonate and black TPE

The over mold with clear polycarbonate and black TPE© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code