Send My Request

Reducing Costs with High-Volume PP Plastic Spacer Sourcing

- Reducing Costs with High-Volume PP Plastic Spacer Sourcing

- Why PP plastic spacer is the economical choice for high-volume applications

- How injection molding delivers scale economies for plastic spacer sourcing

- Key cost drivers in high-volume PP plastic spacer sourcing

- Design-for-manufacturability (DFM) guidelines specific to PP plastic spacers

- Material selection and PP grades: balancing cost and performance

- Quality assurance and process controls that cut costs, not corners

- Supplier selection: what to require from a high-volume PP spacer molder

- Supply chain and logistics strategies to reduce landed cost for plastic spacer programs

- Illustrative cost comparison: injection molding vs. alternative manufacturing methods

- Real-world tactics procurement teams use to lower costs on PP plastic spacer programs

- Brand advantages: why choosing our PP plastic spacer by injection molding reduces your total cost

- Frequently Asked Questions (FAQ)

- What is a PP plastic spacer and where is it commonly used?

- Why choose injection molding over other manufacturing methods for spacers?

- How does tooling cost affect my unit price?

- Can recycled PP be used for spacers?

- How do I ensure quality at scale?

- What lead times should I expect for high-volume PP spacer programs?

- Contact us / View product

- Authoritative references and further reading

Reducing Costs with High-Volume PP Plastic Spacer Sourcing

Why PP plastic spacer is the economical choice for high-volume applications

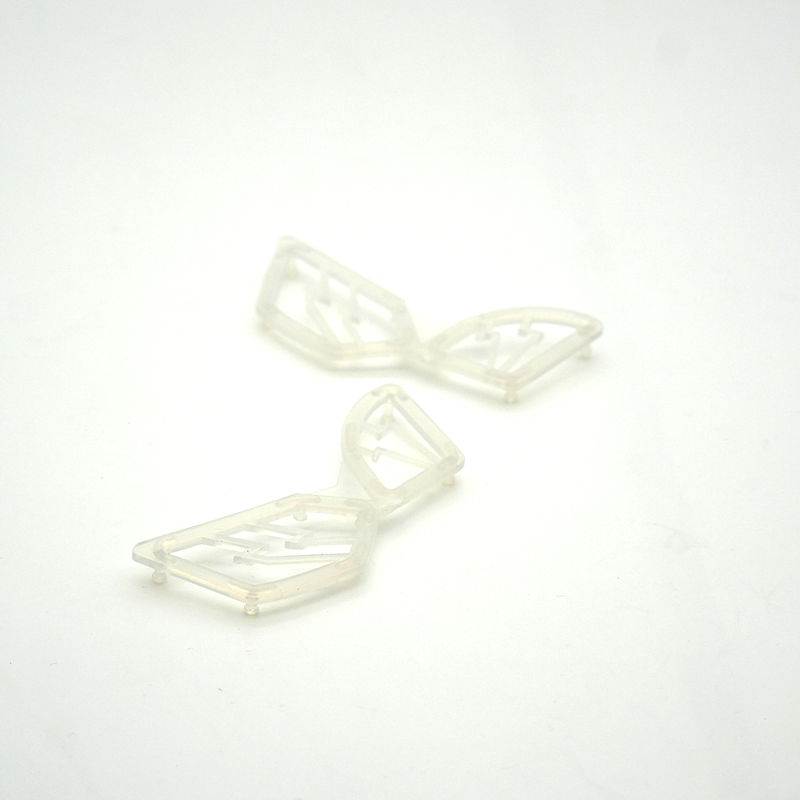

When procurement teams look for durable, lightweight, and cost-effective components, the plastic spacer—specifically the PP plastic spacer by injection molding—consistently ranks highly. Polypropylene (PP) offers excellent balance between performance and cost: it is low density, chemically resistant, and suitable for precision injection molding at high throughput. For applications that demand repeatability, dimensional stability, and low unit cost at scale, PP spacers produced by injection molding are often the optimal solution.

How injection molding delivers scale economies for plastic spacer sourcing

Injection molding is the dominant manufacturing process for high-volume thermoplastic parts. Its advantages for PP plastic spacers include:

- Very low unit cycle time once tooling and process are set.

- High repeatability and tight tolerances with appropriate molds and process controls.

- Ability to use multi-cavity molds to produce dozens or hundreds of spacers per cycle, lowering per-piece amortized tooling cost.

- Minimal secondary operations when designed for molded-in features, reducing labor and handling costs.

Understanding and optimizing these factors is central to reducing landed costs for large-volume spacer programs.

Key cost drivers in high-volume PP plastic spacer sourcing

To reduce total cost, identify and manage the main cost drivers:

- Tooling amortization: Mold cost is fixed; maximizing cavity count and part nesting reduces amortized cost per part.

- Material cost: Resin price and grade selection (virgin PP vs. regrind or recycled content) directly affect unit cost and performance.

- Cycle time: Shorter cycle times reduce machine time and energy per part.

- Scrap and defect rate: Higher yield reduces effective unit cost—invest in process control and quality inspection.

- Secondary operations: Minimizing machining, assembly, or finishing reduces labor and lead time.

- Logistics and inventory: Consolidating shipments, optimizing MOQ, and planning safety stock affect total landed cost.

Design-for-manufacturability (DFM) guidelines specific to PP plastic spacers

Good DFM reduces cycle time, scrap, and tooling complexity. For PP plastic spacer designs, consider:

- Keep wall thickness uniform to avoid sink marks and warpage; use gradual transitions and ribs instead of thick sections.

- Design draft angles (typically ≥1–2°) for easy ejection from the mold.

- Use radiused corners rather than sharp angles to promote consistent flow and reduce stress concentrations.

- Where possible, design features that allow multi-cavity molds (identical parts or family molds) to increase throughput.

- Incorporate molded-in tolerance features instead of relying on post-process machining.

- Consider gate location and flow balance to minimize weld lines in critical areas.

Collaborating with your moldmaker and process engineers early—during prototype and tooling design—avoids expensive iterations later.

Material selection and PP grades: balancing cost and performance

Polypropylene comes in many grades: homopolymer PP, random copolymer, impact-modified, fillers, and UV-stabilized blends. For spacers, typical considerations are:

- Mechanical needs: If the spacer must sustain load, choose an impact-modified or glass-filled grade; if not, a homopolymer PP can be the most economical.

- Thermal resistance: Standard PP has a melting point around 160–170°C but has limited heat deflection; choose grade accordingly.

- Color and aesthetics: Natural PP is cheapest; color masterbatch adds cost.

- Regrind and recyclate: Controlled regrind can cut material costs substantially—ensure consistent quality and regulatory compliance.

Quality assurance and process controls that cut costs, not corners

Quality control (QC) prevents costly returns, recalls, and scrap. Effective QC strategies that reduce overall program cost include:

- First article inspections and PP-specific dimensional studies to validate tooling.

- Statistical process control (SPC) for cavity-to-cavity variation and cycle stability.

- In-line sensors (pressure, temperature, fill time) and automated rejection systems for consistent yields.

- Periodic material verification for melt flow index (MFI) and contamination.

Investing in these controls increases upfront expense but dramatically lowers lifecycle costs.

Supplier selection: what to require from a high-volume PP spacer molder

Choosing the right injection molder is as important as part design. For high-volume PP spacer programs, your supplier should offer:

- Proven experience with multi-cavity PP tooling and long-run campaigns.

- Robust tooling partnerships (local or regional moldmakers) and transparent tooling amortization models.

- ISO 9001 and, where applicable, IATF 16949 or other industry-specific certifications.

- Supply chain resilience: redundancy in resin sourcing, capacity flexibility, and logistics planning.

- Cost transparency: clear quoting that separates tooling, per-piece tooling amortization, material, cycle time, and secondary operations.

Supply chain and logistics strategies to reduce landed cost for plastic spacer programs

Cost reductions are often unlocked by smarter supply chains:

- Consolidate shipments and use vendor-managed inventory (VMI) to lower freight and holding costs.

- Negotiate long-term resin contracts or collaborate with suppliers on resin hedging to stabilize material costs.

- Localize production where feasible to reduce lead time and import duties, or use dual-sourcing to mitigate geopolitical risks.

- Optimize packaging to increase pallet density and reduce transportation spend.

Illustrative cost comparison: injection molding vs. alternative manufacturing methods

Below is an example table showing typical cost components for producing a common PP spacer (20 mm diameter, simple geometry) at different annual volumes. Numbers are illustrative; your program should use supplier quotes for exact budgeting.

| Method | Annual Volume | Tooling Cost (USD) | Unit Material & Process Cost (USD) | Estimated Unit Cost (amortized) (USD) |

|---|---|---|---|---|

| Injection Molding (multi-cavity) | 1,000,000 | USD 45,000 | 0.02 | 0.065 (tooling amortized over volume + process) |

| Injection Molding (single-cavity) | 100,000 | USD 15,000 | 0.03 | 0.18 |

| CNC Machining (PP billet) | 100,000 | USD 0 | 0.50 | 0.50 |

| Thermoforming / Stamp | 100,000 | USD 8,000 | 0.12 | 0.20 |

Interpretation: For high volumes (hundreds of thousands to millions), injection molding with a multi-cavity tool offers the lowest unit cost despite higher tooling investment. Alternative methods may be competitive for low volumes or complex materials but typically can’t match injection molding at scale.

Real-world tactics procurement teams use to lower costs on PP plastic spacer programs

Procurement and engineering teams that consistently lower costs employ these tactics:

- Buyoff-first approach: prototype on low-cost tooling, then validate design before committing to high-cavity production tools.

- Volume bundling: aggregate demand across product lines or regions to increase order volumes and lower per-piece pricing.

- Design simplification: remove non-essential features that add cycle time or secondary operations.

- Material consolidation: standardize on a few PP grades to achieve better pricing and improve supplier leverage.

- Regular cost reviews with suppliers: quarterly metrics on scrap, cycle time, and material usage to drive continuous improvement.

Brand advantages: why choosing our PP plastic spacer by injection molding reduces your total cost

Our company specializes in engineering plastics and high-volume injection molding for components like PP plastic spacers. Here are the competitive advantages we bring:

- End-to-end capability: In-house tooling, molding, and secondary operations minimize handoffs and lead times.

- DFM expertise: Experienced design engineers collaborate early to ensure molds are optimized for high yield and minimal cycle time.

- Quality systems: ISO 9001 and SPC-based production ensure consistent output and low defect rates.

- Material sourcing: Long-term supplier relationships and negotiated resin contracts reduce material volatility risk and cost.

- Flexible capacity: Multi-cavity tooling and scalable floor capacity allow us to service both rapid ramp and long-term steady-state production economically.

- Transparent costing: Clear separation of tooling, per-piece, and logistics in quotations helps sourcing teams make informed decisions.

By partnering with a supplier that can demonstrate these advantages, buyers typically capture the largest share of potential savings without sacrificing quality.

Frequently Asked Questions (FAQ)

What is a PP plastic spacer and where is it commonly used?

A PP plastic spacer is a small component used to maintain gap/clearance, provide insulation, or align parts in assemblies. Common applications include electronics, automotive trim, furniture, fastener isolation, and construction hardware where chemical resistance, low cost, and low weight are required.

Why choose injection molding over other manufacturing methods for spacers?

Injection molding has the lowest unit cost at high volumes, excellent repeatability, and the ability to produce complex features and tight tolerances. For million-piece runs, it’s almost always the most economical choice compared to CNC, stamping, or thermoforming.

How does tooling cost affect my unit price?

Tooling is a fixed upfront investment. The more parts you produce, the lower the tooling cost contribution per part. Multi-cavity molds significantly reduce the amortized tooling contribution per unit.

Can recycled PP be used for spacers?

Yes—regrind or post-industrial recycled PP can reduce raw material cost. However, ensure consistent melt flow, absence of contaminants, and that mechanical properties meet requirements. For critical or load-bearing spacers, a controlled blend or virgin material may be necessary.

How do I ensure quality at scale?

Use strong initial validation (FAI), implement SPC during production, monitor process parameters, and perform regular material checks. Automated inspection (vision systems, CMM spot checks) helps maintain yield as volume increases.

What lead times should I expect for high-volume PP spacer programs?

Typical timelines: 4–8 weeks for prototype/tooling validation on low-cost molds; 8–16 weeks for full-production multi-cavity tooling depending on complexity. After tooling approval, cycle time and available press capacity determine steady-state throughput.

Contact us / View product

Cost efficiency must always be balanced with reliability, which is why procurement teams rely on a detailed quality control checklist for PP plastic spacer suppliers.If you’re evaluating PP plastic spacers for a high-volume program, contact our sales and engineering team to get a tailored cost analysis, DFM assessment, and sample parts. We can provide tooling estimates, multi-cavity options, and volume price breaks to help you optimize total cost of ownership. Email: sales@example.com | Request a quote: https://www.example.com/contact

Authoritative references and further reading

- Polypropylene — Wikipedia: https://en.wikipedia.org/wiki/Polypropylene

- Injection moulding — Wikipedia: https://en.wikipedia.org/wiki/Injection_molding

- PlasticsEurope: Polypropylene (PP) factsheet: https://www.plasticseurope.org/en/about-plastics/what-are-plastics/major-plastics/pp-polypropylene

- ISO 9001 Quality management systems — International Organization for Standardization: https://www.iso.org/iso-9001-quality-management.

PVC vs. ABS in Injection Molding: Material Comparison and Selection Guide

Design Tips for Injection Molding Black POM Spacers at Scale

Metal vs Plastic Inserts: Pros and Cons for Engineering Applications

Sustainable Practices in Insert Injection Molding: A Practical Guide for Manufacturers

FAQs

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Get in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code