Send My Request

A Comprehensive Guide to Insert Molding Technology 2026

Discover Bost's expert guide to insert molding technology 2026. High-quality plastics for superior manufacturing results.

- Introduction to Insert Molding: Combining Strength with Precision

- The Insert Molding Process: A Step-by-Step Breakdown

- Key Advantages and Benefits of Insert Molding

- Common Applications of Insert Molding Across Industries

- Materials Used in Insert Molding: A Synergistic Approach

- Design Considerations for Successful Insert Molding

- Insert Molding vs. Overmolding: Understanding the Differences

- How Customized Solutions Drive High-Performance Part Production

- The Future of Insert Molding: Trends and Innovations

- Conclusion: The Enduring Value of Insert Molding

- About us

- FAQ

- What is insert molding?

- What are the main advantages of using insert molding?

- What types of materials can be used as inserts in insert molding?

- How does insert molding differ from overmolding?

- What industries commonly use insert molding?

- Are there any design limitations or challenges with insert molding?

- Can insert molding be automated?

- What are typical applications of insert molding in electronics?

- References

Introduction to Insert Molding: Combining Strength with Precision

Insert molding is a game changer for modern manufacturing. It's like a glue that holds different materials together, creating strong, high-performance parts. Basically, insert molding is a special kind of injection molding where molten plastic is injected around a part that's already been put in place, called an "insert." Standard injection molding makes solid plastic parts. This technique lets you encapsulate metals, ceramics, or even electronic circuits within a plastic matrix.

More and more, manufacturers are using this technology to make lightweight yet durable parts. According to Business Research Insights, the global custom insert molding service market is growing rapidly. It was valued at about USD 0.99 billion in 2024 and is expected to reach USD 2.21 billion by 2033. This growth shows how important insert molding is to industries like automotive and medical devices. In these industries, it's crucial to mix strength (from metal inserts) and design flexibility (from plastic).

The Insert Molding Process: A Step-by-Step Breakdown

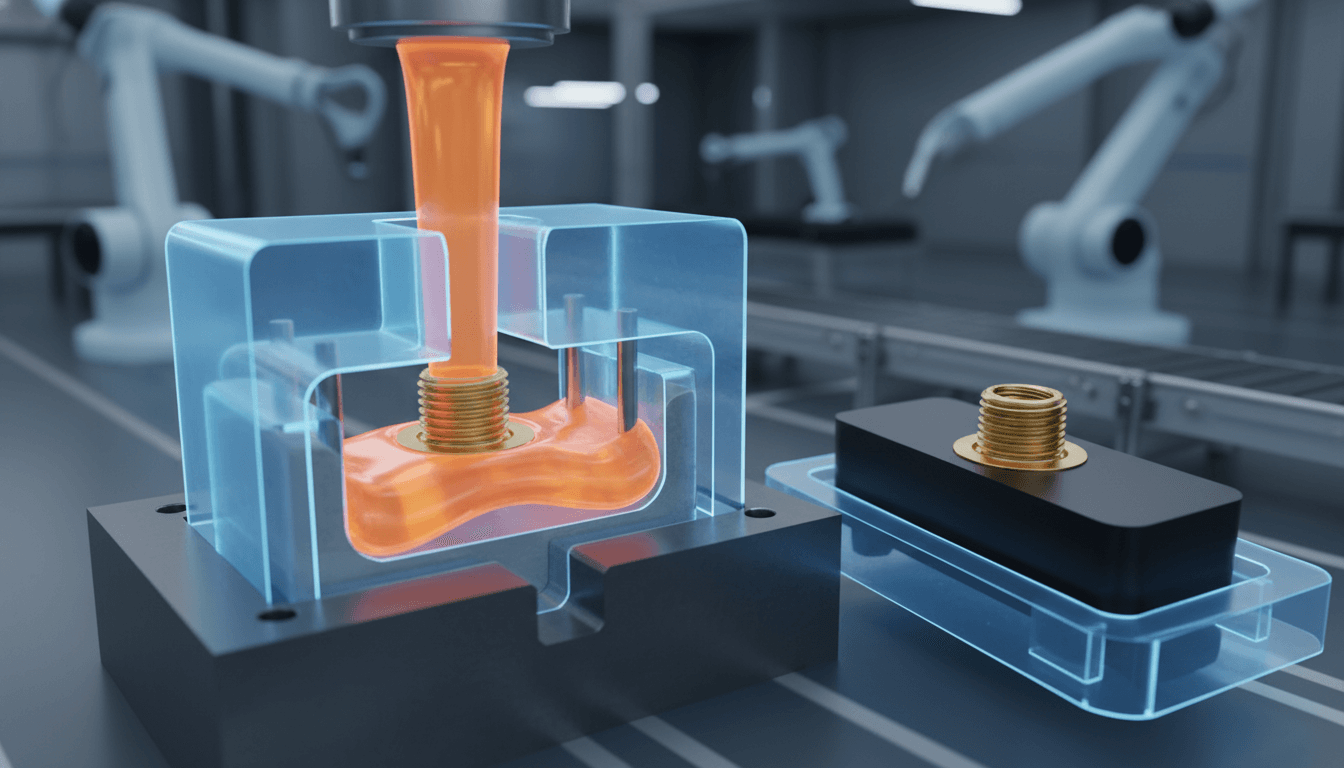

To get the high precision needed for insert-molded parts, manufacturers follow a strict, multi-stage process. Every step is important to make sure the insert is encapsulated right without damaging the component or messing up the structural integrity of the final part.

1. Insert Preparation: Before we start molding, we need to manufacture and prepare the inserts. These inserts can be threaded brass nuts, stainless steel pins, or complex electronic lead frames. This usually means cleaning to remove oils and heating the inserts to match the mold temperature. That improves adhesion and reduces thermal shock.

2. Insert Placement: This is the most delicate step. Inserts are put into the mold cavity, either by hand by an operator or automatically using high-precision robotic arms. It's crucial to get the placement right, because misalignment can lead to mold damage or defective parts.

3. Molding Cycle: Once the mold closes, molten thermoplastic is injected under high pressure. According to the technical info from Tuling, the injection pressures can range from 15,000 to 30,000 psi, depending on the material. This ensures the plastic flows into every crevice around the insert for a secure mechanical lock.

4. Cooling & Ejection: The mold is kept closed while the plastic solidifies. Proper cooling channels are essential to prevent warpage. Once it's cooled, the mold opens and the part is ejected.

5. Quality Control: The last step is a thorough inspection. We check the parts for flash (excess plastic), proper insert location, and adhesion quality to make sure they meet strict dimensional tolerances.

Key Advantages and Benefits of Insert Molding

Adopting insert molding offers some real advantages beyond just making parts. It's a smart move to boost production and improve the performance of the product.

· Enhanced Part Functionality: By putting metal contacts or bushings directly into plastic, manufacturers can make parts that can conduct electricity or bear heavy loads in a lightweight housing.

· Reduced Assembly Time & Costs: In traditional manufacturing, parts might be soldered, glued, or screwed together after they've been molded. Insert molding does away with these extra steps, cutting down on labor and logistics costs.

· Improved Part Strength & Durability: The plastic resin shrinks a little around the insert as it cools, creating a tight mechanical bond. This makes for better pull-out strength and vibration resistance compared to parts put together with fasteners.

· Increased Design Flexibility: Designers can incorporate complex geometries and innovative material combinations that would be impossible to assemble manually.

· Miniaturization & Weight Reduction: Since insert molding removes bulky fasteners and connectors, it allows for smaller, lighter, and more compact designs. This is a critical factor in the aerospace and portable electronics industries.

· Cost Efficiency: Having fewer parts on the production line and more streamlined production lines means you'll end up spending less overall.

· Enhanced Aesthetics: The result is a smooth, polished look with no visible screws or messy adhesives.

Common Applications of Insert Molding Across Industries

The versatility of insert molding has made it a staple in virtually every high-tech sector:

· Automotive: From rugged sensors and control panel switches to specialized gear shift knobs, the automotive industry relies on insert molding for parts that must withstand heat and vibration.

· Electronics: It is essential for manufacturing durable connectors, encapsulating circuit boards, and creating protective housings for delicate sensors.

· Medical Devices: Surgical instruments, dental implants, and precision drug delivery systems utilize insert molding to combine sterile plastic surfaces with robust metal cores.

· Consumer Products: Look at the durable handles on your power tools or the integrated components in kitchen appliances—these are often insert molded for longevity.

· Aerospace: Lightweight structural components that require metal-grade strength for fastening but plastic-grade weight savings.

· Industrial Equipment: Critical valve components, bushings, and bearings are manufactured using this method to ensure reliability in harsh environments.

Materials Used in Insert Molding: A Synergistic Approach

Picking the right materials is key to successful insert molding. How long the part will last depends on how the insert interacts with the molten plastic.

Here are some of the most common inserts that industry experts like Neway Precision talk about:

· Metals: We use brass for threaded nuts, stainless steel for medical and high-strength parts, aluminum for lightweighting, and copper for electrical conductivity.

· Non-Metals: You can use ceramics, glass, and even high-temperature plastics as inserts.

Molding Materials (Thermoplastics) The encapsulating material should provide the necessary environmental resistance and mechanical properties. Some of the most common polymers are:

· Engineering Plastics: ABS, polycarbonate (PC), and nylon (PA6/PA66) are industry standards because they're so tough.

· High-Performance Polymers: PEEK and LCP (liquid crystal polymer) are used in extreme environments.

· Flexible Materials: TPE (thermoplastic elastomers) are used for grips and seals.

Material Compatibility Crucially, the thermal expansion coefficients of the insert and the plastic must be considered. If they differ too drastically, the plastic may crack around the insert as it cools.

Design Considerations for Successful Insert Molding

To avoid costly defects, engineers must adhere to specific design guidelines:

· Insert Design: Inserts should feature undercuts, knurling, or grooves. These features allow the plastic to physically "grab" the insert, providing the mechanical retention needed to prevent rotation or pull-out.

· Mold Design: Mold design plays an important role in insert molding quality.Proper gating and venting are vital to prevent air traps near the insert. Support pins may be needed to keep the insert from shifting during the high-pressure injection phase.

· Tolerance Management: Designers must account for the shrinkage of the plastic. A metal insert will not shrink, so the plastic dimensions must be adjusted to ensure the final part meets specifications.

· Parting Line Considerations: The mold must shut off precisely against the insert to prevent "flash" (excess plastic leaking onto the insert's functional surfaces).

· Automation Potential: For high-volume runs, parts should be designed to allow robotic grippers to easily load the inserts.

Insert Molding vs. Overmolding: Understanding the Differences

While the terms are often used interchangeably, Aberdeen Technologies clarifies the distinct technical differences:

· Defining Insert Molding: This process involves molding plastic around a pre-existing non-plastic component (usually metal). It is typically a "single-shot" process where the insert is placed, and plastic is shot around it.

· Defining Overmolding: This usually refers to molding one plastic material over another pre-existing plastic component (the substrate). It is often a "two-shot" process used to add soft-touch grips (TPE) over rigid handles.

· Key Distinctions: The primary difference lies in the substrate material (metal vs. plastic) and the objective (structural integration vs. surface enhancement).

· Similarities: Both result in integrated, multi-material parts that reduce assembly needs.

How Customized Solutions Drive High-Performance Part Production

When it comes to making high-performance parts, customized solutions are key, especially for processes like insert molding. This technique involves putting a metal or other material insert into a mold before injecting plastic, which makes the part stronger and better. By tweaking the mold design, material choice, and insert placement to meet specific performance needs, manufacturers can boost the part's durability, precision, and how well it works with other components. With custom solutions in insert molding, you can make complex, multi-material parts that take less time to assemble and are cheaper. Because they guarantee that parts fulfill their precise specifications, these solutions are excellent for any type of application, including automotive, electronics, and medical. This leads to better overall performance and more satisfied customers.

The Future of Insert Molding: Trends and Innovations

As Industry 4.0 matures, insert molding is evolving. Insights from MoldAll and Fictiv highlight several emerging trends:

· Automation & Robotics: The integration of 6-axis robots for insert loading is becoming standard, increasing throughput and precision while reducing human error.

· Advanced Materials: Research is pushing the boundaries of conductive polymers and biodegradable plastics, allowing for more sustainable and "smart" insert molded parts.

· Miniaturization: As electronics shrink, insert molding is adapting to micro-molding scales, enabling the production of tiny medical implants and micro-sensors.

· Smart Manufacturing: IoT sensors embedded in molds now monitor pressure and temperature in real-time, predicting maintenance needs before defects occur.

· Sustainability: There is a growing shift toward using recyclable thermoplastic resins and reducing runner waste to minimize the environmental footprint of the process.

Conclusion: The Enduring Value of Insert Molding

Insert molding remains a cornerstone of efficient manufacturing, offering a unique combination of strength, precision, and economic value. By eliminating secondary assembly steps and enabling the creation of complex, multi-functional parts, it empowers engineers to design products that are lighter, stronger, and more reliable. As mentioned by Virtue Market Research, the continued growth of the injection molding sector suggests that insert molding will only become more critical as industries strive for innovation in automotive, medical, and consumer technology.

About us

Bost is a high-tech green energy engineering plastics manufacturer specializing in R&D, production, and sales. We deliver high-quality, sustainable solutions to meet the diverse needs of our customers. Bost holds multiple certifications, ensuring our products meet international safety, quality, and environmental standards.

Product Features:

· Anti-Scar: Resists surface damage.

· Corrosion-Resistant: Durable against chemical exposure.

· Fatigue-Durable: Withstands repeated stress.

· Abrasion-Resistant: Excellent wear resistance.

· High-Temperature Transparency: Stable under heat.

· Enhanced Properties: Improved flame retardancy and thermal conductivity.

Advantages:

· Expert Team: Skilled in plastics modification and production.

· Advanced Production: High-volume, quality-focused manufacturing.

· Material Integration: Combining steel, plastic, and rubber for advanced solutions.

· Sustainability: Eco-friendly processes and materials.

· Customer-Focused: Tailored solutions for customer satisfaction.

FAQ

What is insert molding?

Insert molding is a manufacturing process where pre-formed components (inserts), often made of metal, ceramic, or another plastic, are placed into an injection mold. Molten thermoplastic is then injected around these inserts, encapsulating or bonding with them to create a single, integrated part.

What are the main advantages of using insert molding?

Key advantages include enhanced part functionality, reduced assembly costs and time, improved part strength and durability, increased design flexibility, and the ability to achieve miniaturization and weight reduction in products.

What types of materials can be used as inserts in insert molding?

Inserts can be made from a variety of materials, including various metals (brass, steel, aluminum), ceramics, glass, other plastics, and even electronic components or circuitry.

How does insert molding differ from overmolding?

Insert molding involves molding plastic around a pre-existing non-plastic component (like a metal pin). Overmolding typically involves molding one plastic material over another pre-existing plastic component, often in a multi-shot process to create a soft-touch or aesthetic layer.

What industries commonly use insert molding?

Insert molding is widely used across industries such as automotive, electronics, medical devices, consumer products, aerospace, and industrial equipment due to its ability to create complex, multi-functional parts.

Are there any design limitations or challenges with insert molding?

Challenges can include managing material compatibility (thermal expansion, adhesion), ensuring precise insert placement, designing for proper melt flow around inserts, and accounting for potential insert movement or flash during injection.

Can insert molding be automated?

Yes, insert molding processes can be highly automated, especially for high-volume production. Robots are frequently used for precise and rapid loading of inserts into the mold cavity, improving efficiency and consistency.

What are typical applications of insert molding in electronics?

In electronics, insert molding is commonly used for producing electrical connectors, switches, sensor housings, circuit board encapsulation, and integrated components that require both structural integrity and electrical functionality.

References

· Business Research Insights - Custom Insert Molding Service Market Industry Analysis

· Tuling - Insert Molding vs Overmolding

· Neway Precision - What Types of Materials Are Commonly Used in Insert Molding?

· Aberdeen Technologies - Insert Molding & Overmolding: A Complete Guide

· MoldAll - Cutting-Edge Trends in Injection Molding Technology

· Fictiv - The Future of Injection Molding: 7 Trends to Watch

· Virtue Market Research - Global Injection Molding Market Size, Share, Growth

Recommended for you

FAQ

FAQs

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

You may also like

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Leave a Message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code