Send My Request

Bost Chemical-Resistant Sealing Solutions

Product Overview

Bost Chemical-Resistant Sealing is a High Quality sealing solution made from specially modified engineering plastics. Designed for industrial and commercial applications, it resists aggressive chemicals, high temperatures, abrasion, and fatigue. Backed by Bost’s advanced R&D and production capabilities, this sealing material provides reliable performance and long service life with minimal maintenance.

Key Features

- High chemical resistance: Effective against acids, alkalis, solvents and many industrial fluids.

- Temperature stability: Maintains sealing integrity across wide temperature ranges.

- Abrasion and fatigue resistance: Engineered to withstand repeated motion and wear.

- Low friction and tight sealing: Ensures efficient performance and reduced leakage risk.

- Customizable forms: Available as sheets, rods, molded parts and bespoke profiles.

Applications

Suitable for valves, pumps, flanges, gaskets, chemical processing equipment, oil & gas systems, and any application where durable, chemical-resistant seals are required. Bost sealing materials are especially useful in environments with corrosive media or where long maintenance intervals are essential.

Why Choose Bost

Bost is a professional and innovative high-tech green energy engineering plastics manufacturer focusing on R&D, production and sales. Since its establishment, Bost has committed to producing high-quality and special engineering plastics. Our team excels in material modification, mold design, and combined steel-plastic solutions, ensuring each sealing product meets strict quality and safety standards.

Reliability and Support

Every product is backed by technical support and quality control. Bost offers guidance on material selection, custom machining, and installation to ensure the sealing performs as expected in your specific environment. Our goal is to deliver products that give customers confidence and reduce downtime.

Ordering and Customization

Bost provides standard sizes and custom solutions to fit unique requirements. Contact our team for material certification, sample testing, or to request a quotation. Choose Bost Chemical-Resistant Sealing for proven durability, consistent quality, and trusted performance.

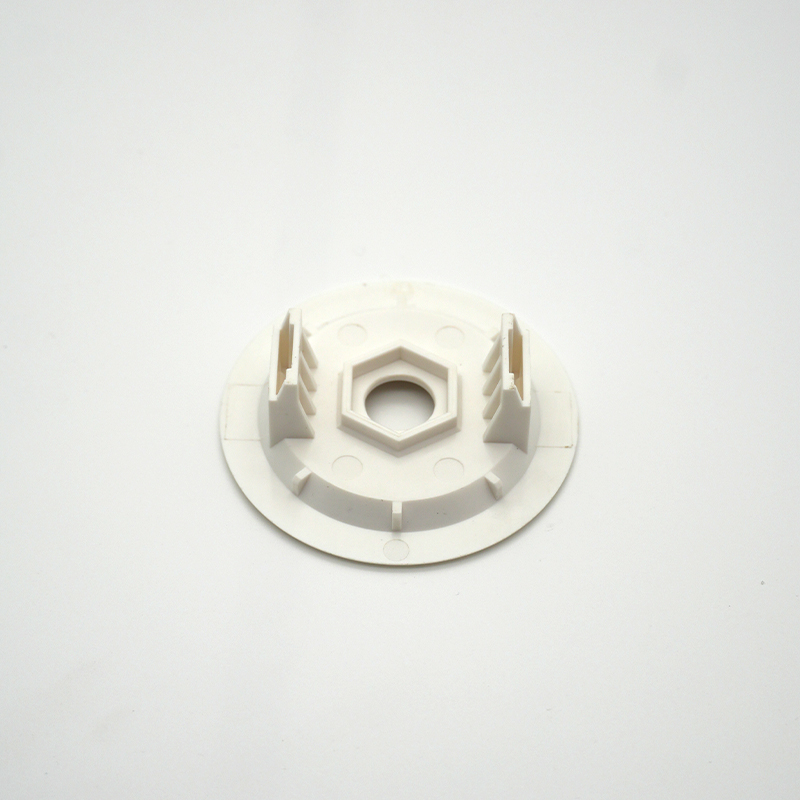

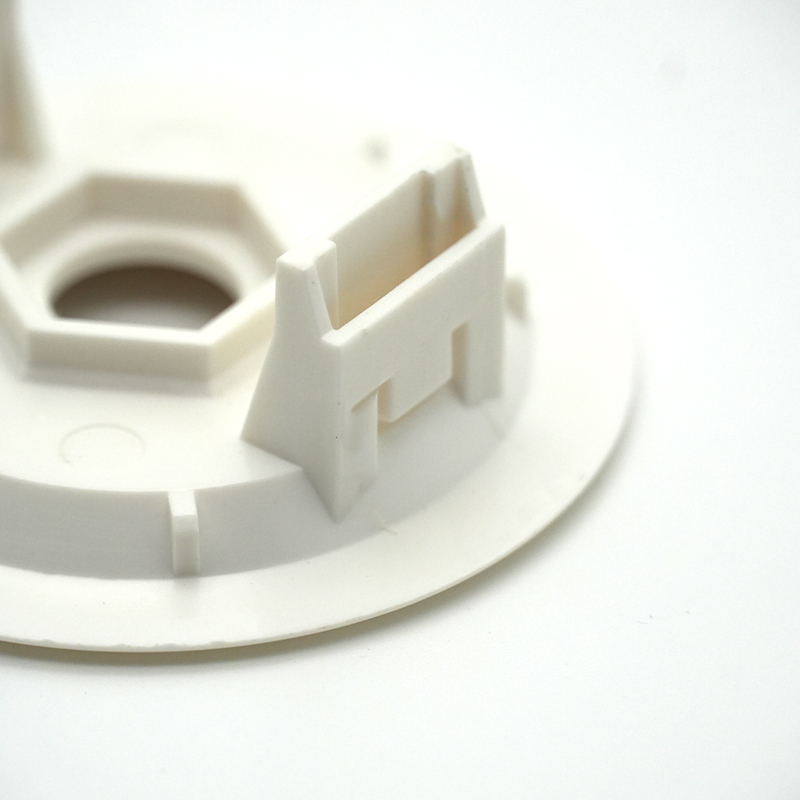

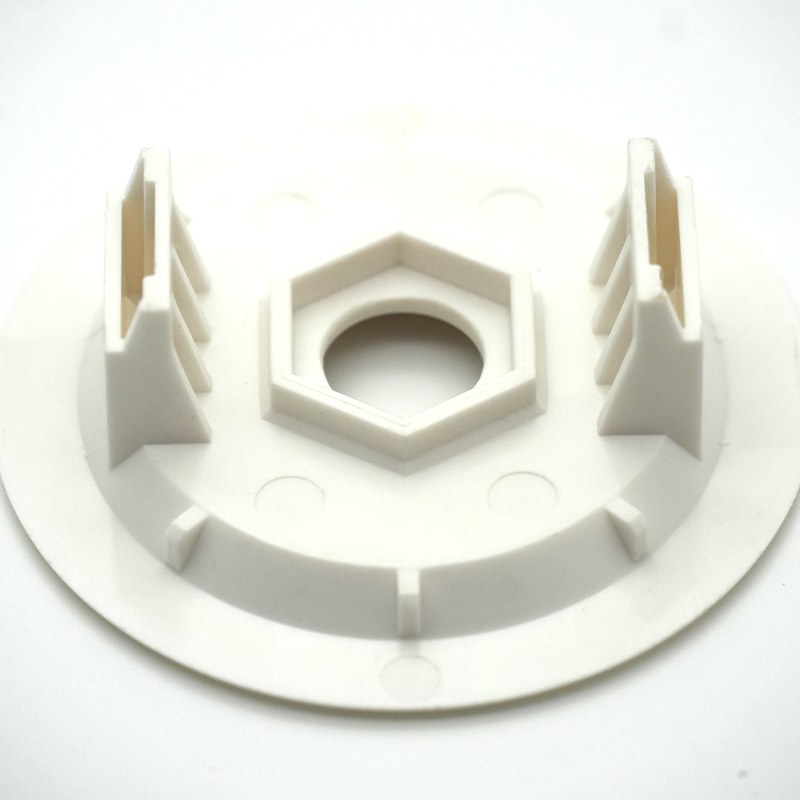

Product Images

Question you may concern

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code