Send My Request

Bost Custom Plastic Injection Molding — High-Performance Engineering Plastics

Product Overview

Bost custom plastic injection molding delivers tailored engineering plastic parts designed for long service life and reliable performance. Backed by a strong R&D team and advanced mold design capabilities, Bost produces components with superior abrasion resistance, corrosion resistance, high-temperature stability, and enhanced toughness. Our green-energy focus ensures production that values sustainability without compromising quality.

Why Choose Bost Custom Plastic Injection Molding?

- Precision and consistency: Accurate mold design and machining guarantee repeatable parts for high-volume production.

- Specialized materials: We work with ultra-abrasion, super-corrosion, high-temp transparent, flame-retardant, and conductive thermoplastic compounds.

- Durability: Enhanced fatigue resistance and toughening options extend component life and lower maintenance costs.

- Integrated solutions: Steel-plastic and plastic-rubber combinations provide high technical performance for complex applications.

- Fast prototyping and production: Rapid tooling and efficient processes speed time-to-market.

Applications

Our custom plastic injection molding parts serve industries such as renewable energy, automotive, industrial machinery, medical devices, and consumer products. Typical uses include housings, gears, wear pads, insulating parts, fluid-handling components, and precision inserts where reliability matters.

Product Value & Customer Benefits

Bost focuses on delivering practical value: lower total cost of ownership through long-lasting materials, reduced downtime, and optimized part design for performance. Customers receive dedicated technical support from concept through mass production—mold design, mechanical processing, and post-mold finishing are all handled in-house for quality control.

Quality & Sustainability

We maintain rigorous testing and quality assurance, combined with green manufacturing practices. Choosing Bost means choosing safer materials, efficient processes, and a partner committed to continuous improvement.

Contact Bost for custom plastic injection molding solutions that match your performance needs and production goals. Our team will help you choose the right material, optimize the mold design, and deliver parts on schedule.

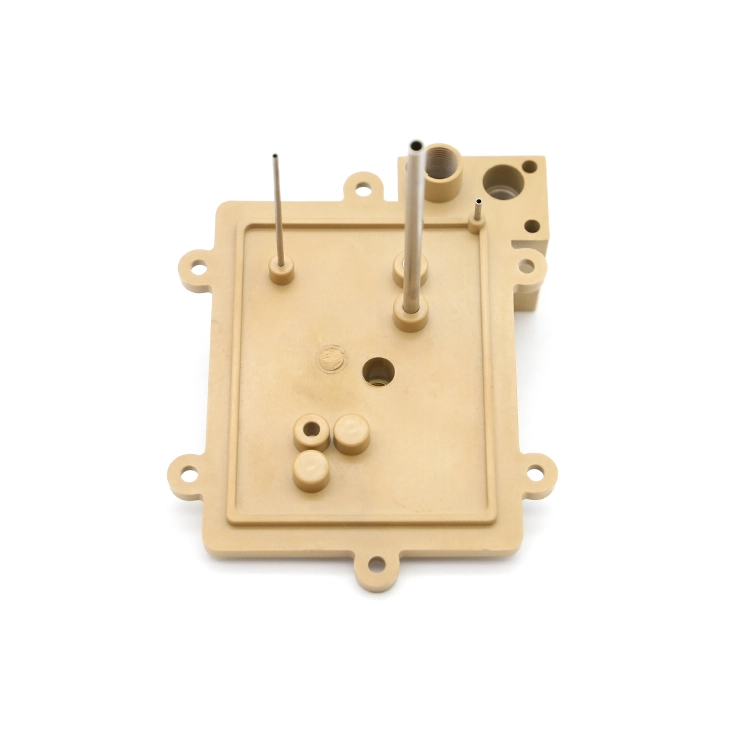

Picture Show

Frequently Asked Questions

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

BOST Injection molding -Customized and OEM Supplier

BOST Injection molding -Customized and OEM Supplier

Customized Plastic Injection molding -faster delivery and economical

Customized Plastic Injection molding -faster delivery and economical© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code