Send My Request

Bost Pipe & Container Closures

Product Overview

Bost pipe and container closures are engineered from advanced specialty plastics to deliver dependable sealing and long-term performance in demanding environments. As a professional green-energy engineering plastics manufacturer, Bost combines material innovation and precision production to offer closures that resist corrosion, wear, high temperatures and fatigue while remaining lightweight and easy to install.

Key Features

- Excellent chemical and corrosion resistance for acids, alkalis and solvents

- High abrasion and fatigue resistance for repeated use and handling

- Stable at elevated temperatures for thermal processes and hot fluids

- Tight sealing to prevent leaks, vapour loss and contamination

- Options for conductive, flame-retardant or transparent grades

- Custom sizes, threads and profiles for pipes, drums and containers

Practical Benefits

Bost closures reduce downtime and maintenance costs by providing reliable seals that last. Their toughness minimizes cracking under stress, while abrasion resistance extends service life in abrasive media. Lightweight design simplifies installation and handling, and custom molding ensures compatibility with existing fittings and standards.

Applications

- Industrial pipelines and fittings

- Chemical storage tanks and drums

- Fuel and lubricant containers

- Water treatment systems

- Renewable energy equipment and battery housings

Why Choose Bost

Bost brings deep expertise in modifying engineering plastics to meet real-world needs. We focus on practical performance: achieving superior sealing, enhanced toughness, and targeted properties like flame retardancy or conductivity. Our production team supports mold design, precision manufacturing and quality control to ensure consistent product performance.

Technical Support & Customization

We offer material selection guidance, custom mold design and testing to match your sealing, temperature and chemical requirements. Bost works closely with customers to deliver closures that integrate seamlessly into your systems.

Order & Service

Contact Bost for samples, technical data sheets and quotes. Our responsive team ensures fast lead times and after-sales support to keep your operations running smoothly.

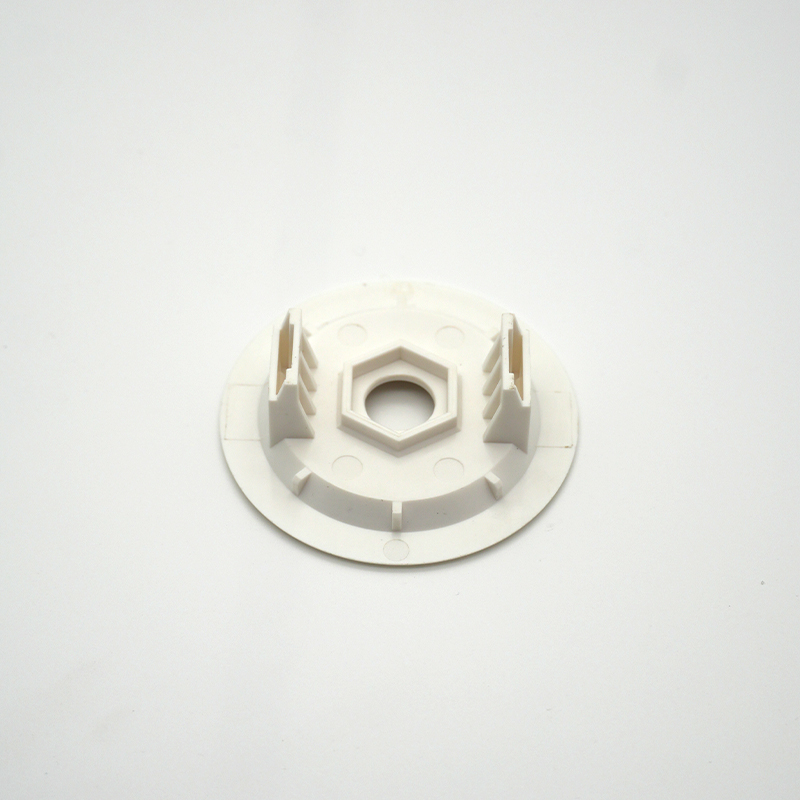

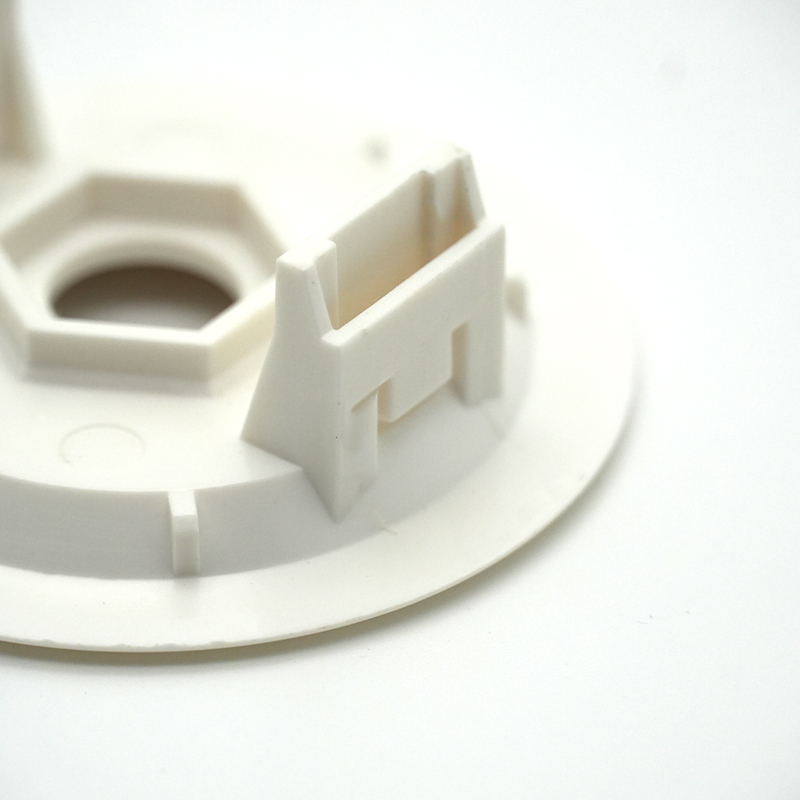

Picture Show

Q&A

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code