Send My Request

China Custom Plastic Injection Molding by Bost

Bost — China Custom Plastic Injection Molding with High-Performance Engineering Plastics

Bost is a professional, innovative and green high-tech manufacturer specializing in engineering plastics R&D, production and sales. We offer China custom plastic injection molding services using advanced modified plastics to meet demanding applications.

Why choose Bost?

- High performance materials: ultra abrasion resistant, superior corrosion resistance, excellent fatigue durability and high-temperature transparency.

- Special properties: anti-scar, enhanced toughening, flame retardant options and thermally conductive formulations.

- Custom shapes and parts: sheets, rods and precision molds made to your specifications, including steel-plastic and plastic-rubber combinations.

What we deliver

Our China custom plastic injection molding service covers prototype to mass production. Bost combines a strong plastics modification R&D team with skilled tooling and machining capabilities. We design and manufacture molds, optimize material formulas, and deliver parts that meet mechanical, thermal and chemical requirements.

Benefits for your project

- Reliable performance: parts that resist wear, corrosion and fatigue, extending product life.

- Design flexibility: tailored materials and mold solutions for tight tolerances and multi-material assemblies.

- Eco-conscious production: we follow green manufacturing practices to reduce waste and energy use.

Fast, clear service

Bost makes ordering simple: share drawings or samples, get a quick quote, approve prototypes, and move to efficient production. Our team supports material selection and process suggestions to ensure cost-effective, durable results.

Choose Bost for China custom plastic injection molding when you need high-quality, specially modified engineering plastics and precise mold solutions. Contact us today for a quote and start building stronger, longer-lasting products with materials designed for real-world demands.

Product Image

Q&A

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Customized Plastic Injection molding -faster delivery and economical

Customized Plastic Injection molding -faster delivery and economical

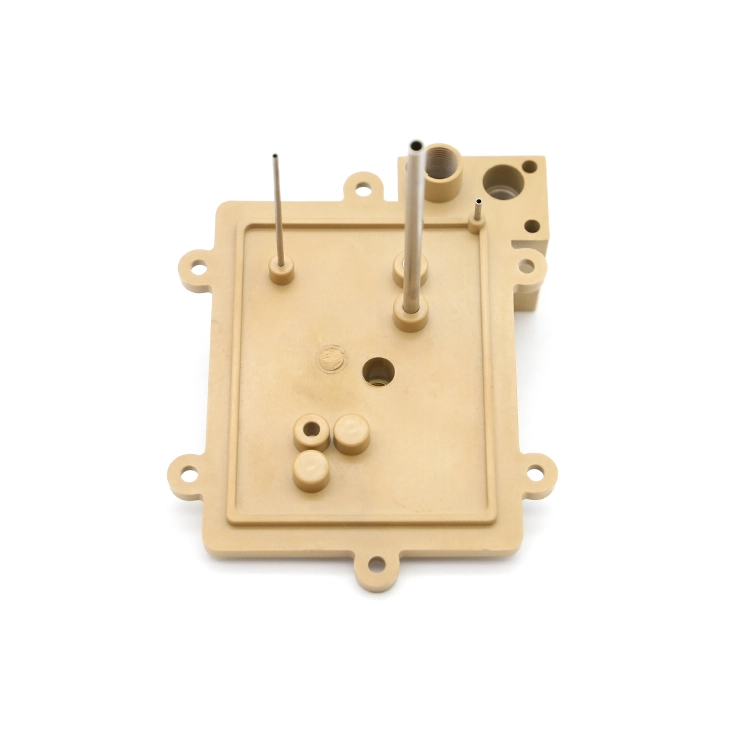

The Bost custom PPO flow valve by injection molding

The Bost custom PPO flow valve by injection molding© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code