Send My Request

Selecting Surface Finish and Coating for Black POM Spacers

- Selecting Surface Finish and Coating for Black POM Spacers

- Why surface finish matters for engineered plastic components

- Key performance drivers

- Common as-molded finishes and when to use them for black POM spacers

- Surface treatments to improve adhesion and performance on POM

- Coating options for black POM spacers and their trade-offs

- Design and manufacturing considerations for production of coated black POM spacers

- Testing and validation best practices for engineered plastic components

- Cost vs performance: building a decision matrix

- Case examples: selecting finishes for typical applications

- How Bost’s black POM spacer supports your engineered plastic components strategy

- Inspection, traceability, and supplier qualification

- Implementation checklist before production run

- Frequently Asked Questions (FAQ)

- Q: Do coatings always improve wear life for black POM spacers?

- Q: What surface treatment provides the best adhesion on POM?

- Q: How much coating thickness should I expect and how does it affect tolerances?

- Q: Can I plate metal onto a POM spacer?

- Q: Which is more cost-effective: polishing the mold or applying a coating?

- Q: How should I test adhesion and wear during qualification?

- Contact Bost / See product

- Authoritative references and further reading

Selecting Surface Finish and Coating for Black POM Spacers

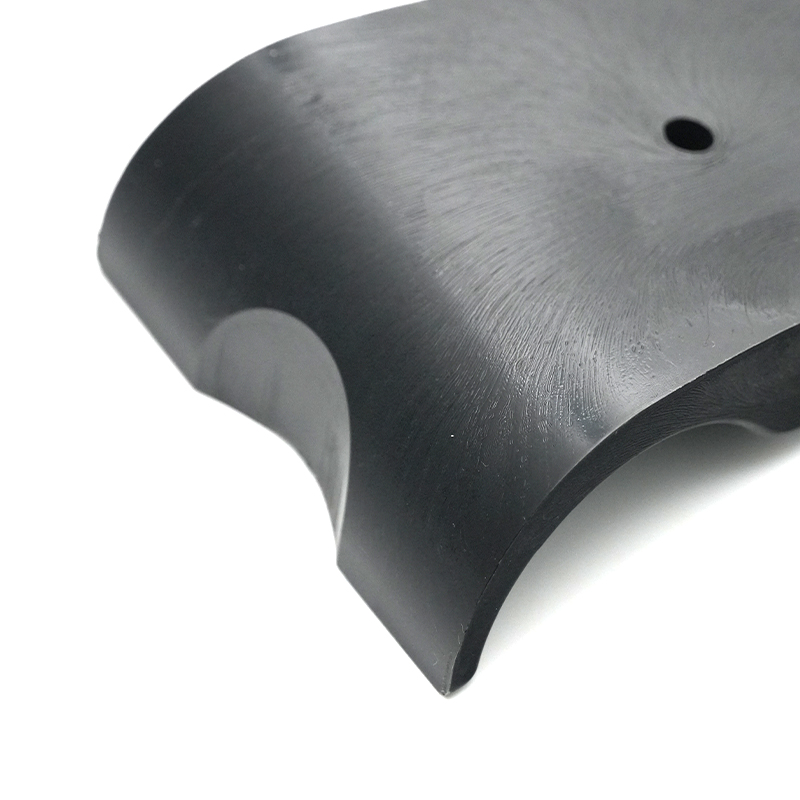

Bost’s black POM spacer made by injection molding delivers superior wear resistance and dimensional stability, ensuring precise positioning in demanding applications. This injection-molded black POM wear-resistant spacing product is designed for durability and long-lasting support in assemblies that rely on engineered plastic components. Choosing the right surface finish and coating is critical to getting the expected friction, durability, chemical resistance, and appearance from these spacers. This article explains practical selection criteria, common finishes and coatings, processing considerations, and test/inspection guidance so design and procurement teams can make informed choices for production and end-use.

Why surface finish matters for engineered plastic components

Surface finish affects multiple performance attributes of a black POM spacer: friction against mating parts, wear rate, dirt accumulation, sealing behavior, and cosmetic appearance. For engineered plastic components such as positioning spacers, small changes to surface roughness or coating chemistry can change wear life by orders of magnitude under sliding contact. POM (polyoxymethylene) inherently has low surface energy and good wear properties, but its surface is also relatively inert, which influences how well coatings adhere and how treatments modify friction.

Key performance drivers

When specifying finishes and coatings, prioritize these application-driven factors: contact load and sliding speed, environment (temperature, humidity, chemicals), dimensional tolerances, surface compatibility with mating materials, visual requirements, and cost/manufacturing throughput. Balancing these factors helps select an engineered solution that maximizes the value of the injection-molded black POM spacer.

Common as-molded finishes and when to use them for black POM spacers

Injection molding surface finish options typically mirror the mold surface treatment. Using the correct mold polish or texture can deliver the needed performance without secondary operations. Common as-molded finishes include:

- Textured (matte) finish: mask surface defects, reduce glare, and trap lubricant films. Good for visible components and where minor micro-asperities help retain lubrication.

- Gloss/polished finish: lower friction and less wear particulate generation in sliding assemblies; used when tight friction control and cleanliness are required.

- Highly polished mirror finish: for precision guides or seals where low asperity contact is essential; more expensive mold prep but can extend wear life.

- As-molded with ejector-pin marks: acceptable for non-critical spacer locations, but may require post-processing or coatings if contact stresses concentrate at marks.

For many applications, Bost’s black POM spacer performs well as-molded with a controlled gloss level. If wear or friction is critical, consider mold polishing to a specified Ra value and pair with a compatible coating or surface treatment.

Surface treatments to improve adhesion and performance on POM

POM has low surface energy, which makes coating adhesion challenging. Surface activation steps are commonly required before applying functional coatings. Typical treatments include:

- Flame treatment - rapid and effective for large batches; increases surface energy by oxidizing the top layer.

- Corona or plasma treatment - controlled, consistent surface activation; plasma provides the best performance for small parts and precision coating adhesion.

- Grit blasting - mechanically increases surface area; useful when combined with primers but can alter dimensions and generate debris.

- Chemical etching or primer layers - primers chemically bond to POM and provide a good base for paints or functional coatings.

Choose the treatment compatible with production volume, tolerance sensitivity, and the selected coating chemistry. For engineered plastic components that require high coating adhesion, plasma plus a tailored primer is often the most reliable combination.

Coating options for black POM spacers and their trade-offs

Below is a summarized comparison of commonly used coatings and functional finishes for POM spacers. The table focuses on wear behavior, friction, chemical resistance, adhesion difficulty, and typical cost level.

| Coating / Finish | Primary Benefit | Relative Friction | Adhesion Difficulty on POM | Typical Cost Impact |

|---|---|---|---|---|

| As-molded, polished | Low friction, low cost | Low | None | Minimal |

| PTFE or fluoropolymer coating | Very low friction, good chemical resistance | Very low | Moderate (surface prep needed) | Moderate |

| Parylene (conformal vacuum-deposited) | Uniform thin film, good wear and barrier | Low | Low to moderate | High |

| Polyurethane/epoxy paints | Color/appearance and abrasion resistance | Medium | High unless primer/plasma used | Low to moderate |

| Dry-film lubricants (moly/PTFE) | Reduced friction, improved run-in | Low | Moderate | Low |

| Metal vapor deposition (thin metal) | Conductive or decorative finish | Varies | High | High |

Selection guidance: for most wear-critical spacer applications where friction reduction is primary, PTFE or dry-film lubricants paired with proper surface activation deliver the best value. Where chemical or barrier performance is paramount (e.g., harsh solvents), Parylene can provide excellent sealing and wear resistance but at a higher unit cost.

Design and manufacturing considerations for production of coated black POM spacers

When moving from prototype to production, align part design, mold finish, coatings, and assembly methods early. Key considerations include:

- Tolerancing: Coatings add thickness; specify tolerances that account for coating thickness or require post-coating machining/laser trimming if needed.

- Batch processing and throughput: Some coatings (Parylene, vacuum metallization) have longer lead times and batch constraints. Choose processes that match production cadence.

- Adhesion process control: Document plasma/primer parameters and include verification steps in the process control plan to avoid batch failures.

- Quality inspection: Develop acceptance criteria for coating thickness, adhesion (cross-hatch or peel tests), tribological performance, and visual defects.

- Repairability: Consider whether a damaged coating can be repaired in the field or requires full replacement of the spacer.

Testing and validation best practices for engineered plastic components

Before approving a coating for production use on black POM spacers, perform targeted tests that reflect end-use stresses:

- Tribological testing - pin-on-disk or reciprocating wear tests using mating material to quantify wear rate and friction coefficient.

- Adhesion testing - cross-hatch tape tests or peel tests after environmental conditioning.

- Chemical resistance - soak or wipe tests with expected solvents, lubricants, and cleaners.

- Thermal cycling - evaluate performance through operating temperature range to detect cracking or delamination.

- Dimensional assessment - measure critical dimensions before and after coating to ensure tolerances remain within specification.

Document pass/fail criteria and run pilot lots to confirm reproducibility. Reliable test data reduces warranty risk and supports supplier qualification of engineered plastic components.

Cost vs performance: building a decision matrix

Use a simple decision matrix to weigh cost, performance, and manufacturability. Below is an example matrix (qualitative) you can adapt for your project.

| Option | Wear Resistance | Friction | Adhesion Risk | Unit Cost Impact |

|---|---|---|---|---|

| Polished as-molded | Good | Low | Low | Minimal |

| PTFE coating | Very good | Very low | Moderate | Moderate |

| Parylene | Excellent | Low | Low | High |

| Dry-film lubricant | Good | Low | Moderate | Low |

Match the option to the top two project priorities. If minimizing total lifecycle cost is primary, a polished as-molded spacer with design features to distribute load may be best. If maximizing run-in life in high-cycle sliding is critical, invest in PTFE or Parylene despite higher up-front cost.

Case examples: selecting finishes for typical applications

Example 1: A precision linear guide using a black POM spacer that slides against anodized aluminum. Requirement: low friction, long wear life, and consistent dimensional control. Recommendation: Polished as-molded finish plus PTFE topcoat with plasma pretreatment to ensure adhesion.

Example 2: An exterior automotive trim spacer exposed to road salts and cleaning chemicals. Requirement: chemical resistance and stable appearance. Recommendation: Parylene coating for barrier protection, with design allowances for coating thickness and a high-durability mold texture for appearance.

How Bost’s black POM spacer supports your engineered plastic components strategy

Bost’s black POM spacer made by injection molding combines the dimensional stability of POM with process controls to deliver consistent part geometry. The product is engineered for wear resistance and precise positioning, making it an excellent base part for additional surface treatments. Bost partners with coating specialists and uses validated surface activation methods so customers receive spacers that meet both mechanical and coating adhesion requirements. Benefits include:

- Repeatable molded geometry that minimizes post-process adjustments

- Compatibility with common treatments (plasma, flame) and coatings (PTFE, dry-film lubricants, Parylene)

- Quality control plans that include coating adhesion and tribology testing

- Production scalability for prototype to high-volume programs

Inspection, traceability, and supplier qualification

For critical assemblies, require traceability for batch, molding parameters, and coating lot numbers. Include inspection checkpoints for coating thickness, adhesion, and dimensional compliance. When qualifying suppliers of engineered plastic components, request process capability (Cp/Cpk) data for critical dimensions and documented coating process windows. This reduces risk of field failures and supports continuous improvement.

Implementation checklist before production run

Use this checklist to ensure readiness:

- Define performance targets: friction coefficient, allowable wear volume, environmental resistance

- Select finish/coating and document surface prep method

- Prototype and run tribo/adhesion/chemical tests to validate choice

- Update CAD tolerances to account for coating thickness

- Agree inspection and acceptance criteria with suppliers

- Plan for pilot run and monitor first-article inspection

Frequently Asked Questions (FAQ)

Q: Do coatings always improve wear life for black POM spacers?

A: Not always. Coatings can reduce friction and wear but must be compatible with POM and the mating material. Poor adhesion or inappropriate coating thickness can cause flaking or increased wear. Validate through tribological testing and adhesion checks.

Q: What surface treatment provides the best adhesion on POM?

A: Plasma treatment combined with an appropriate primer typically gives the most consistent adhesion for subsequent coatings on POM. Flame treatment is effective at scale, while grit blasting is mechanical and may alter tolerances.

Q: How much coating thickness should I expect and how does it affect tolerances?

A: Coating thickness varies by process: dry-film lubricants and PTFE can range from 1 to 10 microns, Parylene from 1 to 25 microns, and paints from 20 to 100 microns. Always specify tolerances relative to the post-coating dimension or plan for selective masking and post-coating machining if needed.

Q: Can I plate metal onto a POM spacer?

A: Direct metal plating on POM is difficult due to low surface energy. It usually requires aggressive pretreatments or conductive interlayers. Consider metallization only when absolutely required and after technical feasibility studies.

Q: Which is more cost-effective: polishing the mold or applying a coating?

A: Polishing the mold gives permanent as-molded finish with minimal per-part cost but higher mold preparation cost. Coatings add per-part processing cost but can provide functional properties not achievable by polishing alone. Choose based on required function and volume.

Q: How should I test adhesion and wear during qualification?

A: Use industry-standard adhesion tests (cross-hatch/tape, peel tests) and application-specific tribology tests (pin-on-disk, reciprocating wear) under representative loads and speeds. Include environmental conditioning before testing.

Contact Bost / See product

If you need assistance selecting the right surface finish or coating for your black POM spacer or want a sample run for validation, contact Bost’s technical sales team. Request a datasheet, sample parts, or testing protocol to accelerate your design validation and supplier qualification.

Authoritative references and further reading

- Polyoxymethylene (POM) - Wikipedia: https://en.wikipedia.org/wiki/Polyoxymethylene

- Injection molding - Wikipedia: https://en.wikipedia.org/wiki/Injection_molding

- Delrin by DuPont (POM product info): https://www.dupont.com/brands/delrin.

- Coatings for plastics overview - AZoM: https://www.azom.com/article.aspx?ArticleID=11957

- About plastics - PlasticsEurope: https://www.plasticseurope.org/en/about-plastics/what-are-plastics/major-plastics

Environmental Impact and Recycling of PE Plastic Bushes

top high-performance polymers for medical devices 2026

Overmolding and Insert Molding Techniques for Plastics

best polymers for high-temperature seals 2026

FAQs

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Get in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code